Missile-borne electronic product storage period acceleration test method based on multistage acceleration factors

An acceleration factor and accelerated test technology, which is applied in the direction of measuring electricity, measuring electrical variables, environment/reliability testing, etc., can solve the problem of poor verification effect during the storage period of weaponry electronic products, inability to trigger product failures, and inability to respond to weaponry activation Can wait for the problem, to achieve the effect of accurate verification results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

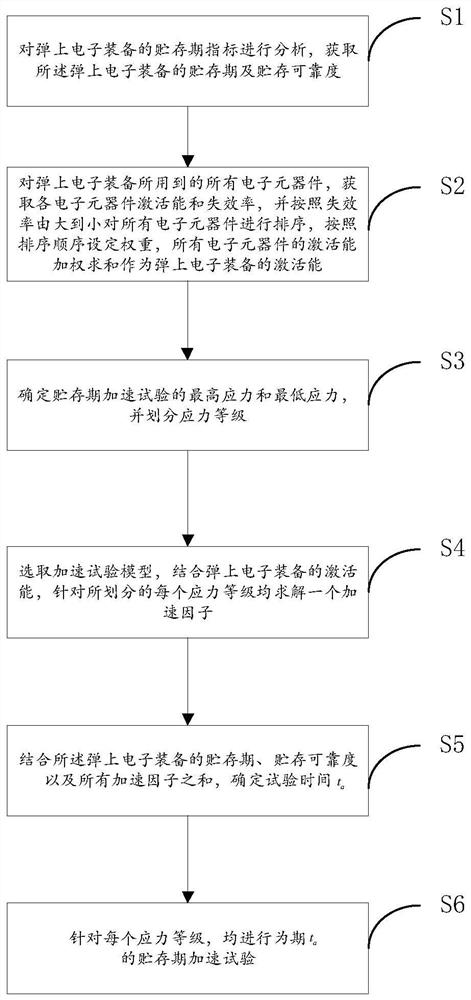

[0030] The invention provides an accelerated test method for the storage period of the electronic product on the bomb based on the multi-level acceleration factor, and its flow process is as follows figure 1 shown, including the following steps:

[0031] S1. Analyze the storage period index of the electronic equipment on the missile, and obtain the storage period and storage reliability of the electronic equipment on the missile; firstly, analyze the storage period index of the weapon equipment, and obtain the storage period and the corresponding The period is generally expressed by time t, and the unit is hour, and the storage reliability is generally expressed by γ, which is dimensionless.

[0032] S2. Obtain the activation energy and failure rate of each electronic component for all the electronic components used in the electronic equipment on the bomb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com