High-altitude projection fire extinguishing equipment

A technology of fire extinguishing equipment and hot air balloon, which is applied in fire rescue and other fields, and can solve the problems of small impact on the ground, affecting fire extinguishing efficiency, and scattering of sand and soil, and achieves high fire extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

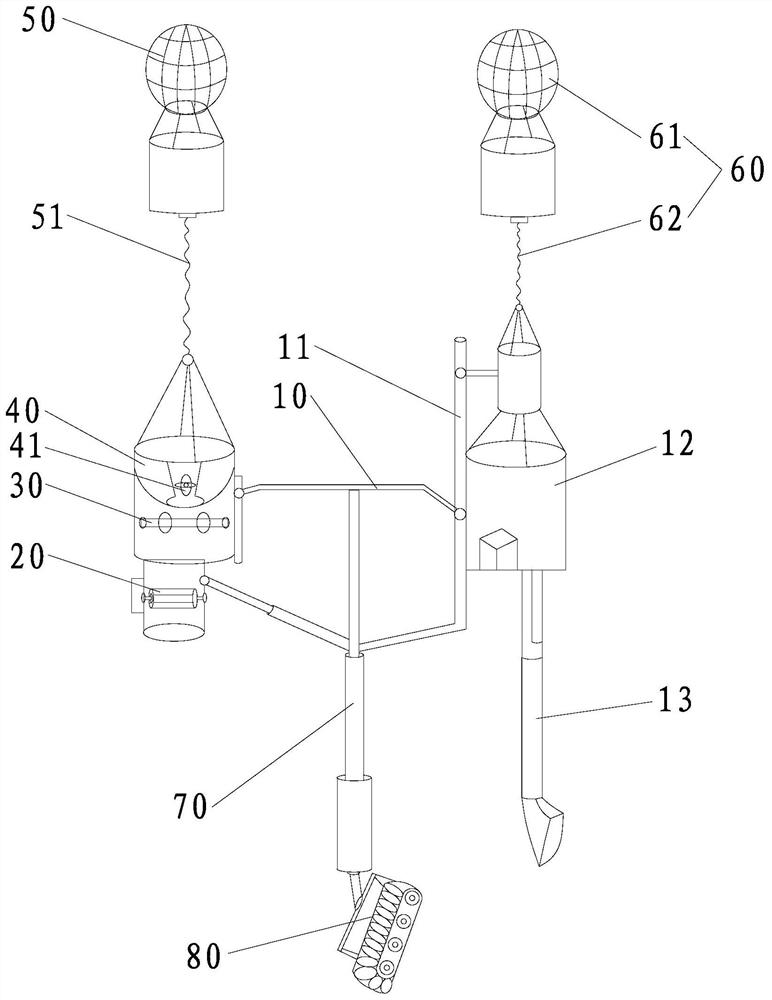

[0033] Such as figure 1 As shown, this embodiment provides a high-altitude projectile fire extinguishing equipment, including a bracket 10, a projectile device 20 fixedly connected to the support 10, a crushing device 30 located above the projectile device 20 and connected to the feed port of the projectile device 20, located at The feeding box 40 above the crushing device 30 and connected to the feed port of the crushing device 30, the first hot air balloon 50 above the feeding box 40, and the first stay rope connected between the first hot air balloon 50 and the support 10 51, wherein, the material inlets of each of the above devices are located at the upper end of the corresponding device, and the material outlets are located at the lower end of the corresponding device, and each device is fixedly connected to the bracket 10 respectively. The discharge port of the projecting device 20 is arranged vertically downward or inclined downward relative to the horizontal plane. In ...

Embodiment 2

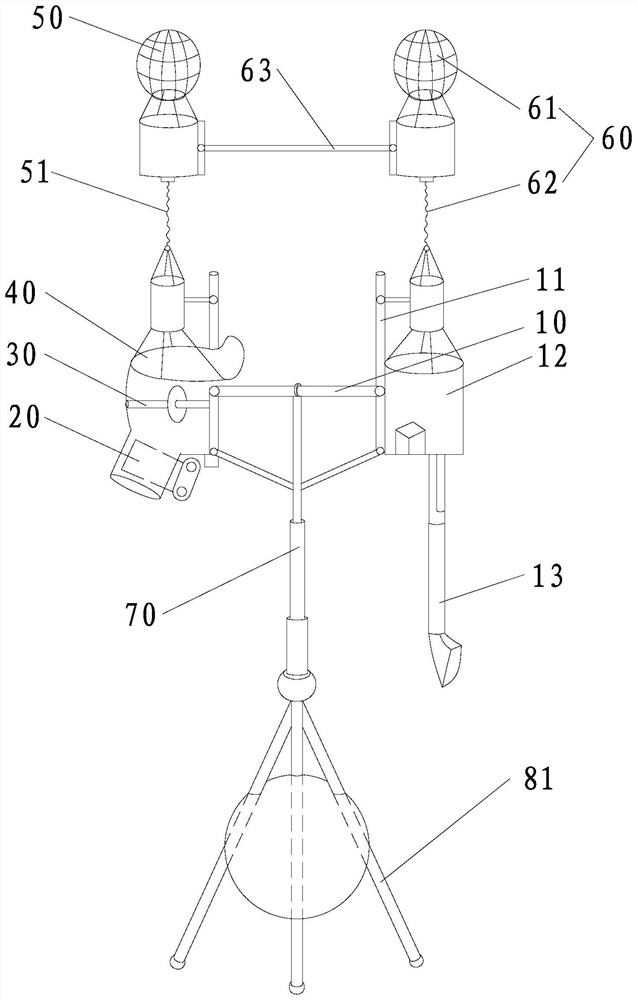

[0041] Such as figure 2 As shown, the difference between the high-altitude projectile fire extinguishing equipment provided by this embodiment and the first embodiment is that this embodiment uses a triangular support base 81 instead of a crawler-type walking chassis 80, so that the entire equipment can be directly lifted by a hot air balloon without the need Move to the fire site by walking on the ground, and the deployment speed is relatively fast.

[0042] Secondly, in this embodiment, a tie rod 63 is connected between the first hot-air balloon 50 and the second hot-air balloon 61, which facilitates the two hot-air balloons to work together.

[0043]In addition, in this embodiment, the discharge port of the projecting device 20 is vertically arranged downwards relative to the horizontal plane, and the feeding box 40 in this embodiment is not provided with a pre-crushing mechanism. At the same time, the shell of the projecting device 20, The casing of the crushing device 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com