A kind of positive and negative extrusion forming die and forming method of curved generatrix shell

A forward and reverse extrusion and forming die technology, applied in metal extrusion dies and other directions, can solve the problems of uneven deformation and large differences in mechanical properties, achieve uniform strain, solve uneven deformation, and promote the effect of forward flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

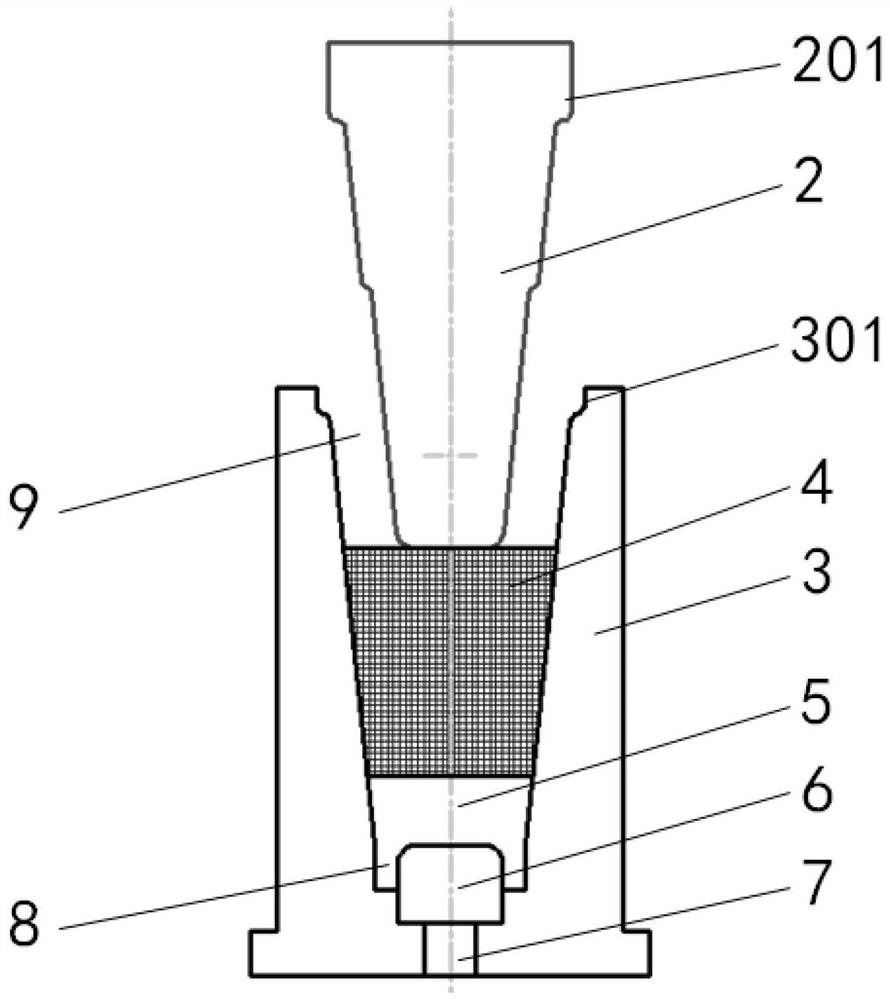

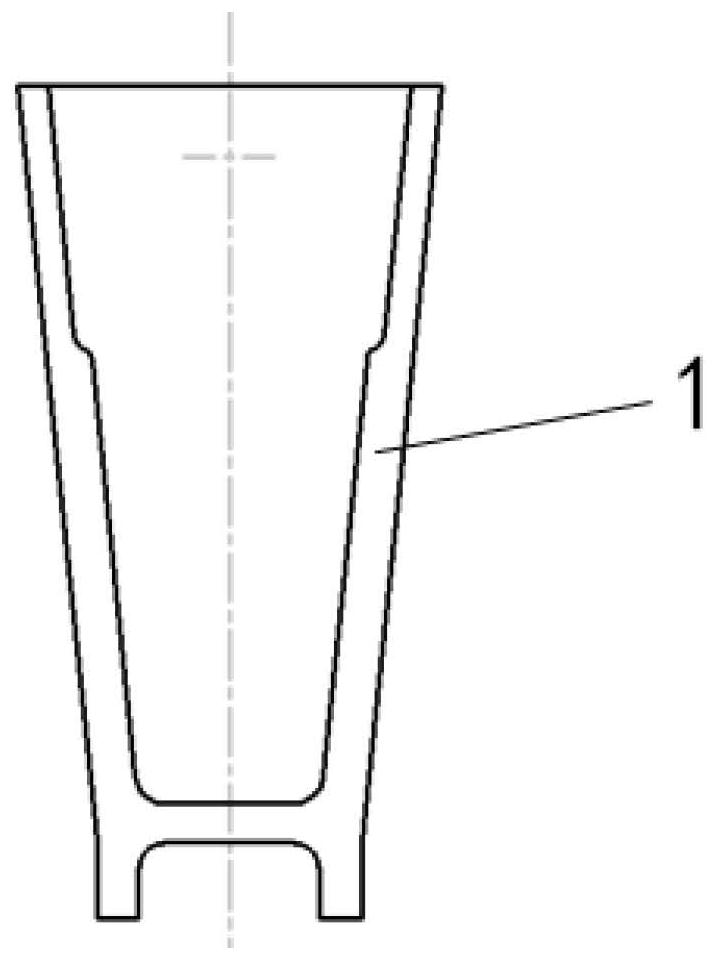

[0046] see image 3 , a method for positive and negative extrusion forming of a curved generatrix shell, using the positive and negative extrusion forming mold of the curved generatrix type shell in the first embodiment, the specific steps are as follows:

[0047] S1: The upper platen drives the extrusion punch 2 to press down, and the blank 4 at the lower end of the extrusion punch 2 flows forward and fills the positive extrusion forming space 5, so as to increase the strain of the dead zone material;

[0048] S2: the extrusion punch 2 continues to press down, the blank 4 at the lower end of the extrusion punch 2 flows in reverse and fills the forming cavity 9;

[0049] S201: The extrusion punch 2 continues to press down, and the blank 4 at the lower end of the extrusion punch 2 flows to the material flow groove 8, which further increases the material flow in the dead zone of the material, so as to ensure the uniformity of the curved generatrix shell 1 deformation;

[0050]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com