A continuous washing device for polyphenylene sulfide resin

A technology of polyphenylene sulfide resin and washing device, which is applied to mixers with rotary stirring devices, transportation and packaging, separation methods, etc., can solve the problem of small processing capacity, large energy consumption of washing liquid and solvent, and large consumption of washing liquid And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

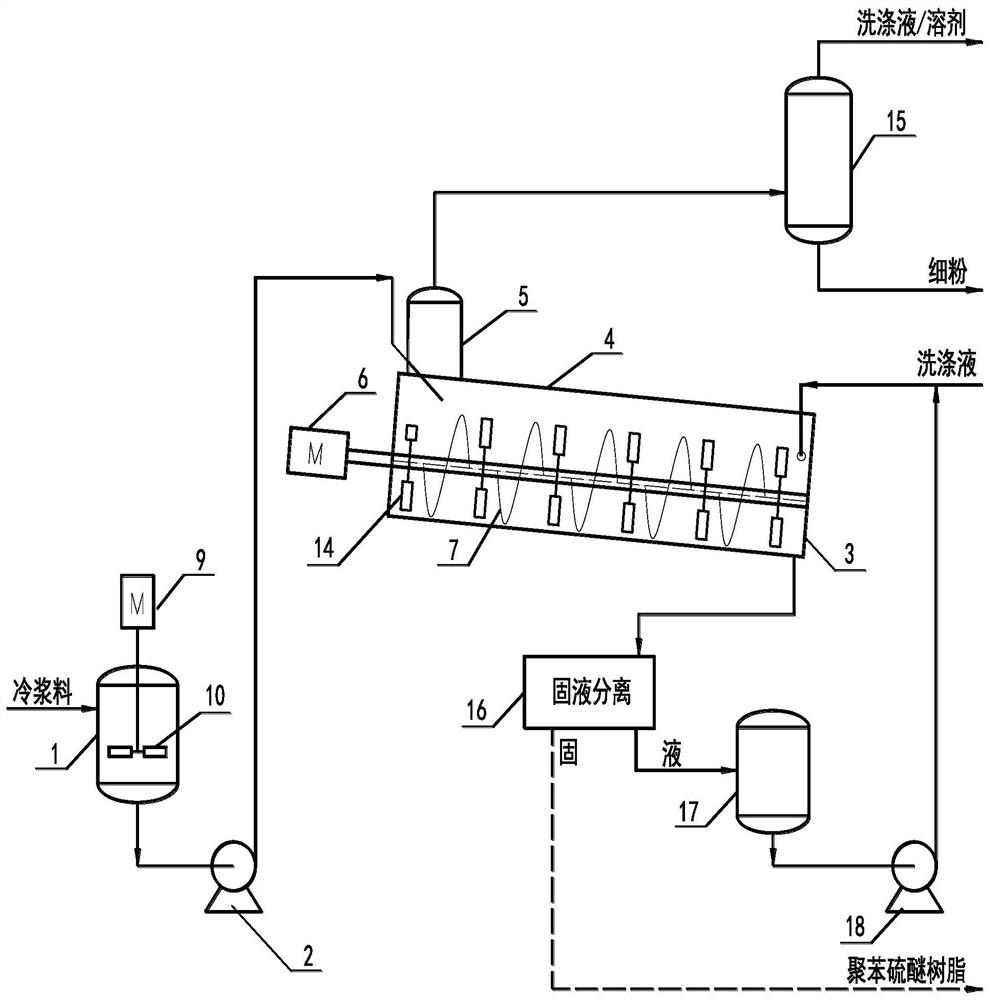

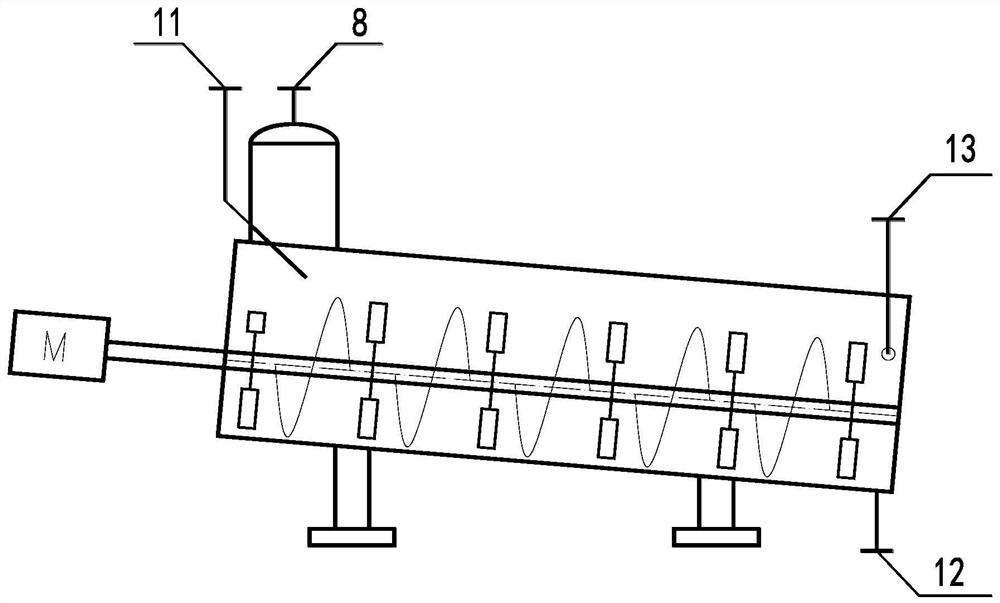

[0038] Such as Figure 1-2 As shown, the continuous washing device for polyphenylene sulfide resin includes a feeding mechanism, a washing mechanism 3 , a precision filter 15 and a solid-liquid separator 16 .

[0039] Wherein, the washing mechanism 3 includes a horizontal cylinder 4 arranged obliquely and a vertical cylinder 5 connected thereto, and the vertical cylinder 5 is installed on the upper part of the relatively higher side of the horizontal cylinder 4 . Such as figure 2 The left end of the middle horizontal cylinder 4 is higher than the right end, the inclination angle between the horizontal cylinder 4 and the horizontal plane is 10°, the inclination angle between the vertical cylinder 5 and the horizontal plane is 90°, and the vertical cylinder 5 is installed on the horizontal cylinder The left end upper part of body 4, both form " L " shape structure. Hereinafter, the relatively higher side and the relatively lower side of the horizontal cylinder 4 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com