Diaphragm water pump

A diaphragm and water pump technology, applied in the field of diaphragm water pumps, can solve the problems of troublesome diaphragm replacement, increase work cost, increase work cost and labor intensity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

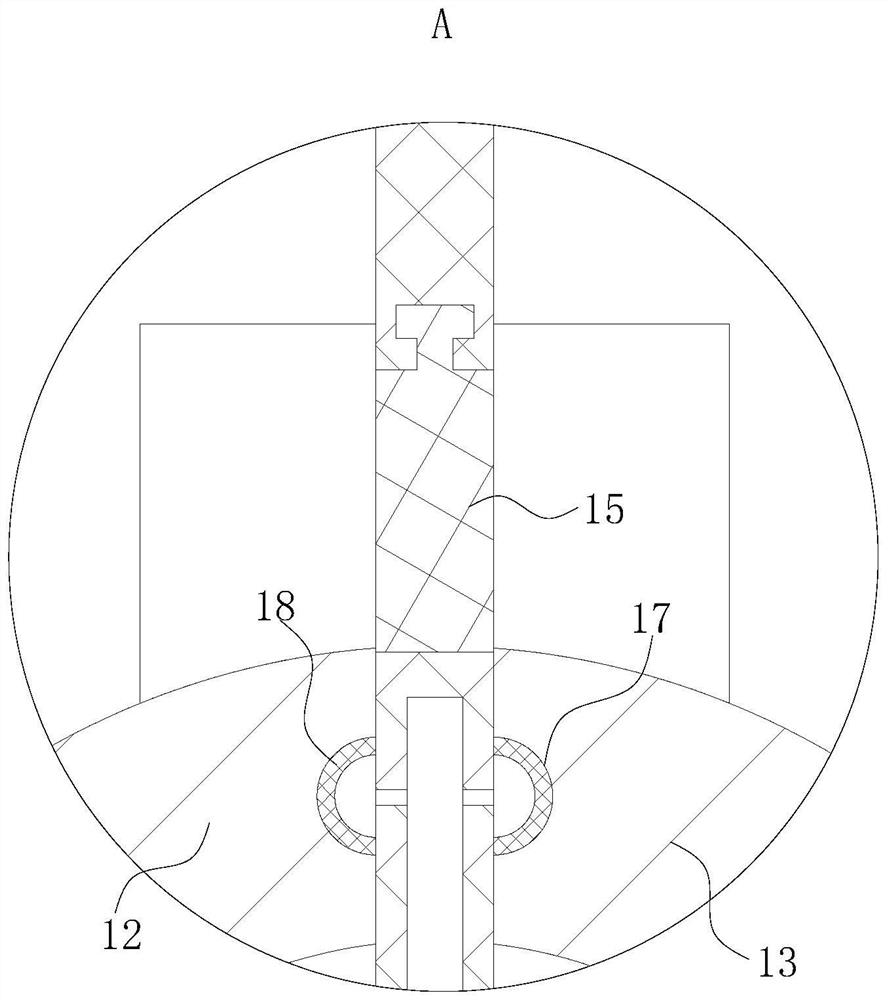

[0034] As an embodiment of the present invention, a circular groove 27 is opened in the inner wall of the driving rod 25, and the circular groove 27 is not connected with the outside; the inner wall of the circular groove 27 is provided with evenly arranged strip-shaped grooves 28, and the strip Shaped groove 28 is all communicated with air groove 21; Said driving rod 25 opposite side is provided with the chute of uniform arrangement in driving rod 25 inwalls, and chute is communicated with round groove 27 by through hole; Each described chute Sliding shafts 29 are connected to the inner walls of the grooves through spring interaction, and the end faces on the opposite side of the sliding shafts 29 are arc-shaped; each said gap 16 is provided with evenly arranged arc-shaped grooves 291 in the inner wall, and the arc-shaped grooves 291 Cooperate with the sliding shaft 29; both sides of the drive rod 25 are provided with evenly arranged trapezoidal grooves 292 in the inner walls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com