Product waterproof performance detection device

A detection device and product technology, applied in the direction of liquid tightness measurement using liquid/vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

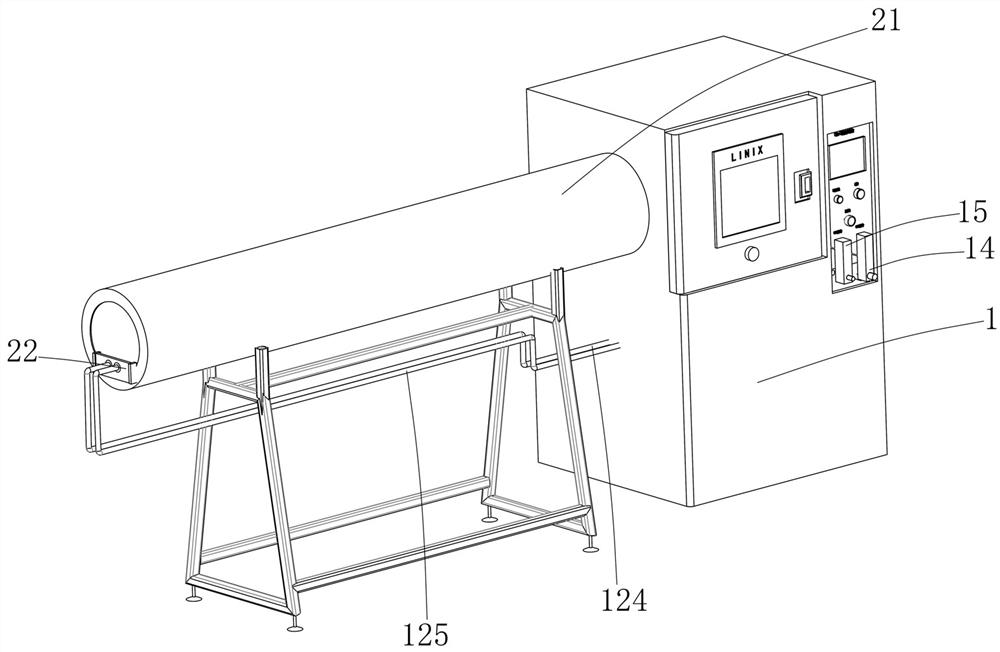

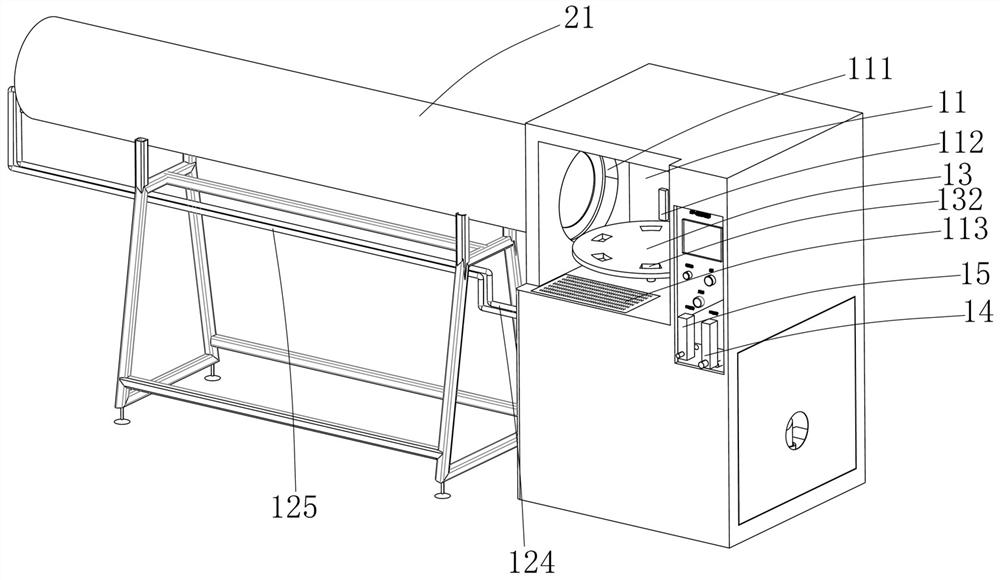

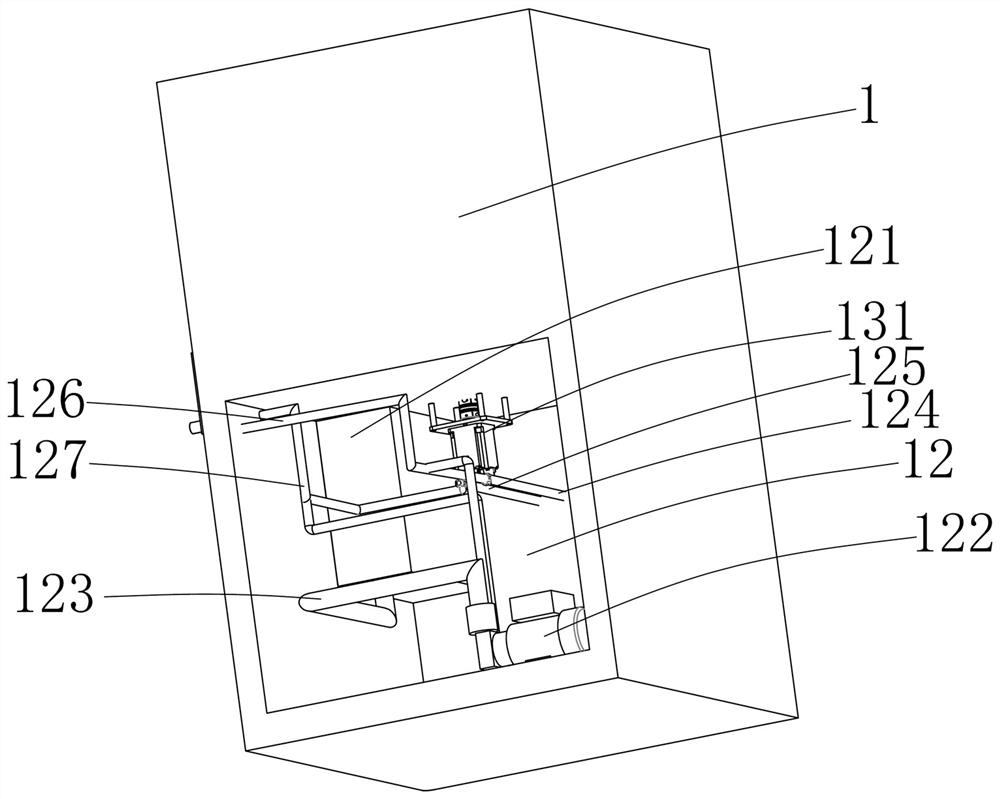

[0017] Such as Figure 1-3 As shown, a product waterproof performance detection device includes a detection box 1, and the detection box 1 is provided with a storage chamber 11 for placing the product to be tested and a working chamber 12 below the storage chamber 11. The storage chamber 11 is provided with a The turntable 13 that places the product to be tested and can rotate horizontally, one side of the storage chamber 11 is provided with a water inlet 111 for spraying water to the product to be tested, and one side of the detection box 1 is provided with a water spray mechanism connected to the water inlet 111 , the working chamber 12 is provided with a water delivery mechanism for delivering water to the water spraying mechanism. The setting of the above-mentioned turntable allows products to be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com