Cleaning device

A cleaning device and a cleaning tank technology, which are applied in cleaning flexible objects, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as residual glue, substrate or cover hanging on the wall, and secondary pollution of products, and achieve improved Cleaning effect, effect of reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

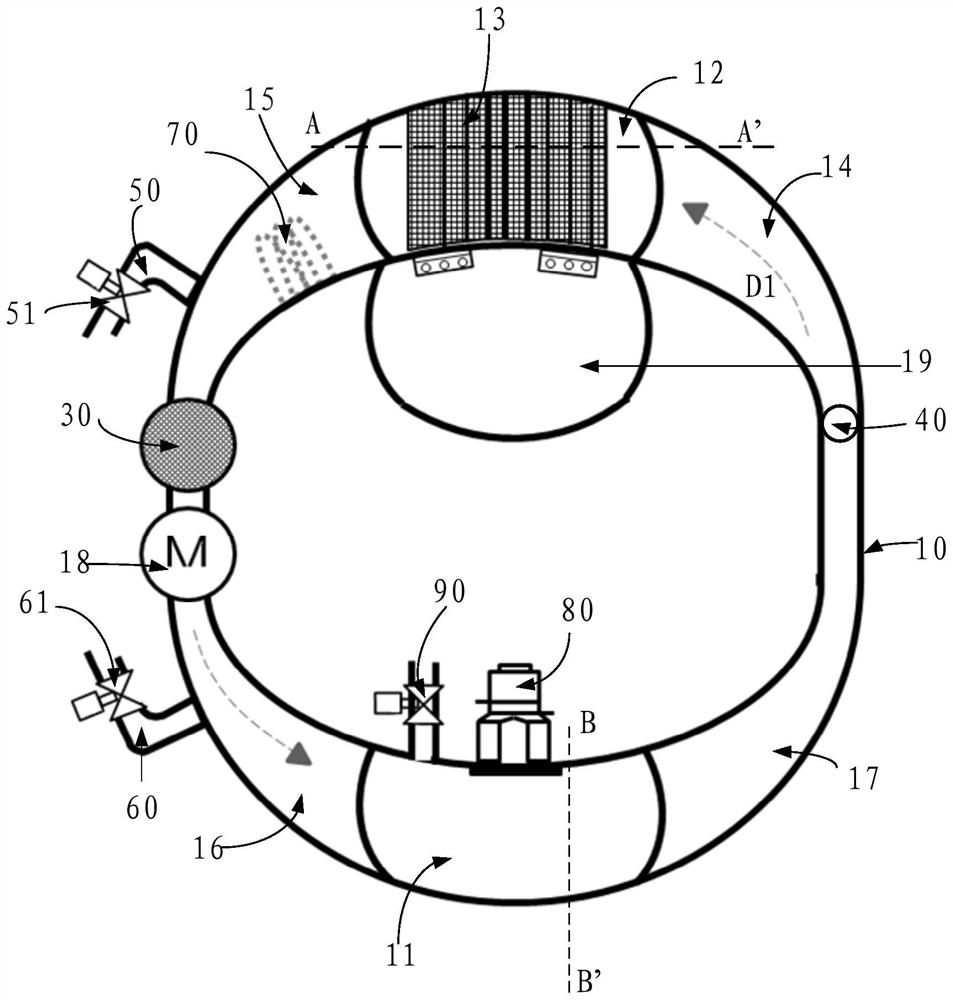

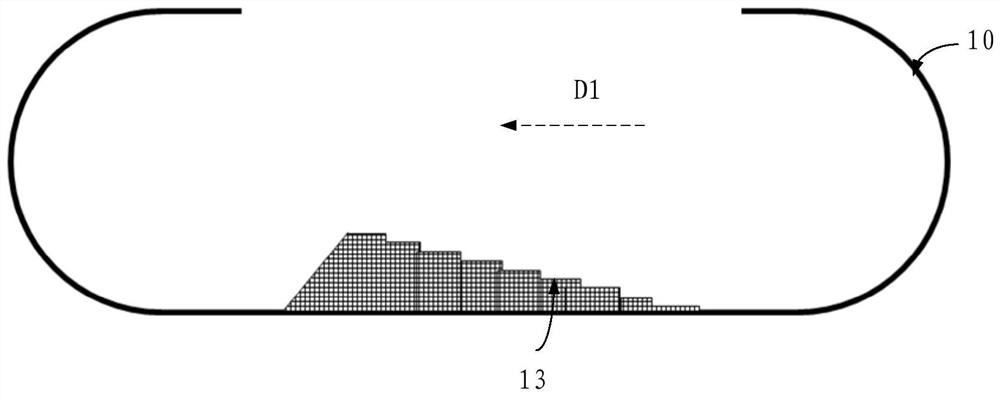

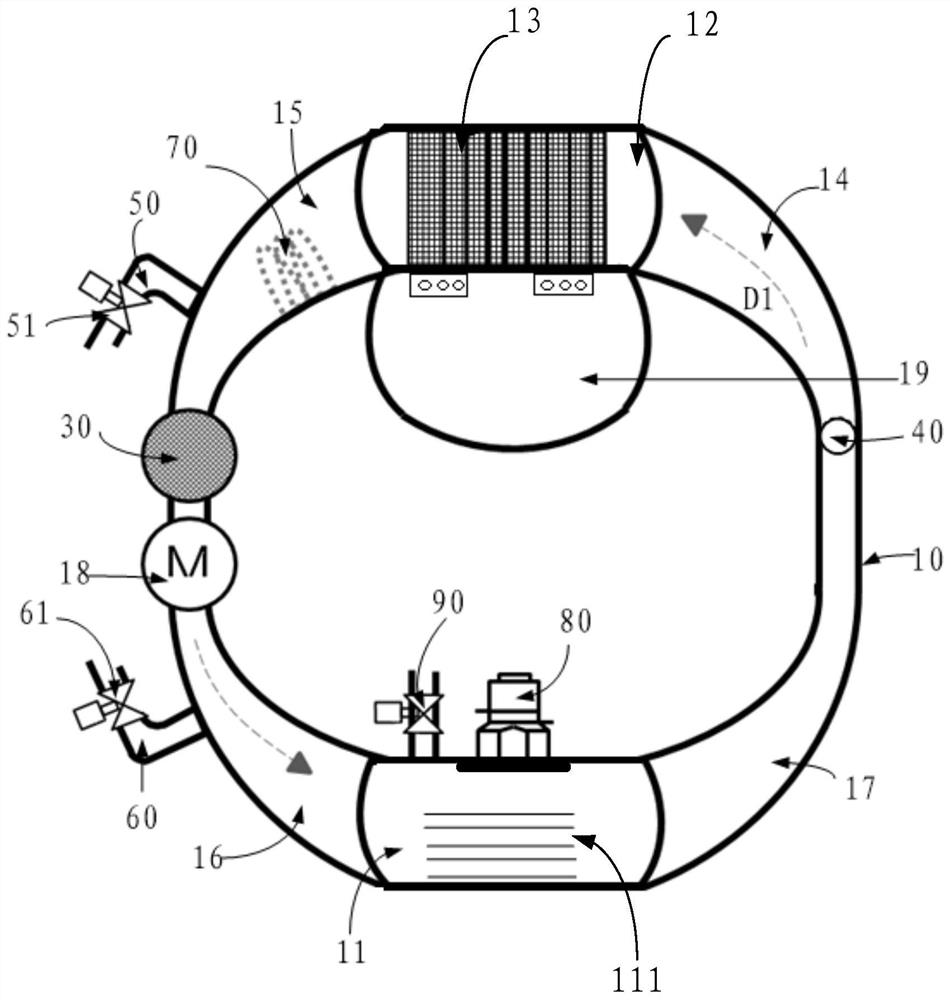

[0024] see figure 1 The embodiment of the present application provides a cleaning device, including a cleaning tank 11 and a settling tank 12, wherein the settling tank 12 is connected to the cleaning tank 11, and the cross-sectional area of the largest cross-sectional position of the settling tank 12 is greater than that between the settling tank 12 and the cleaning tank 11. The cross-sectional area of the largest cross-sectional position between; the cleaning liquid flows into the settling tank 12 from the cleaning tank 11 horizontally during cleaning.

[0025] Wherein the "cross-section" in the embodiment of the present application refers to the section perpendicular to the horizontal plane, such as figure 1 As shown, "cross section" refers to the section along the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com