Steel pipe rotary flushing device

A steel pipe and water flushing technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as misjudgment and alarm of flaw detection work, failure to wash the steel pipe wall, troublesome cleaning by customers, etc., to achieve flushing High quality, stable operation, rinse clean without residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

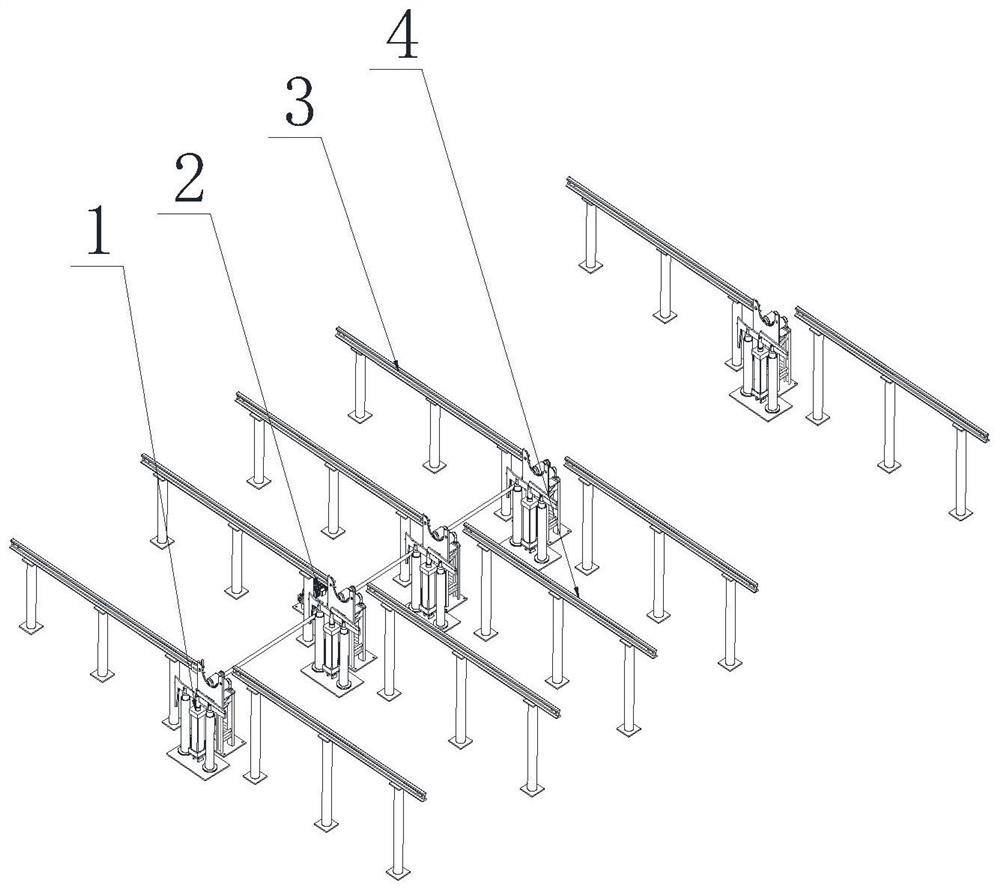

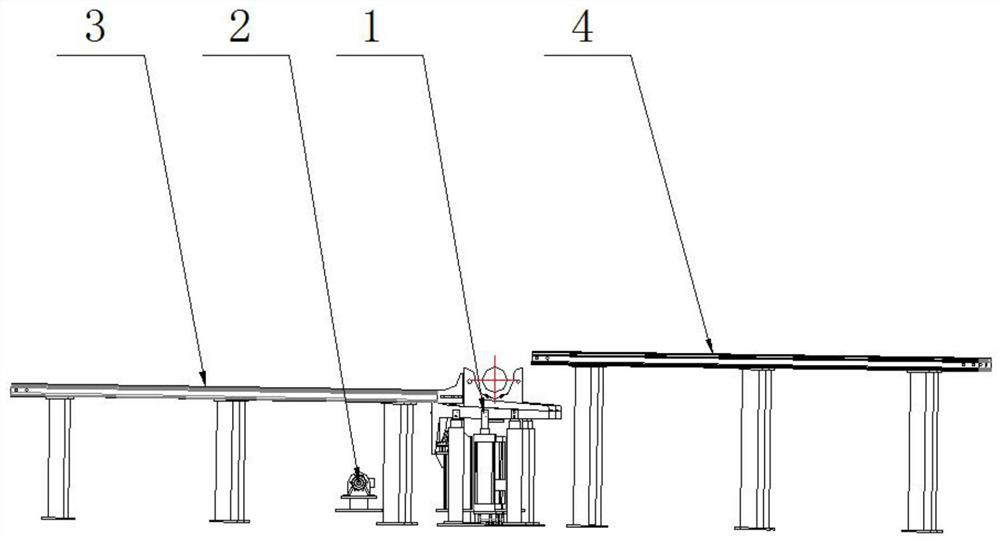

[0026] A steel pipe rotary flushing device, which consists of a feeding platform 3, a feeding platform 4, a pipe transfer mechanism 1, and a rotating mechanism 2. The frame and the unloading platform are located on both sides.

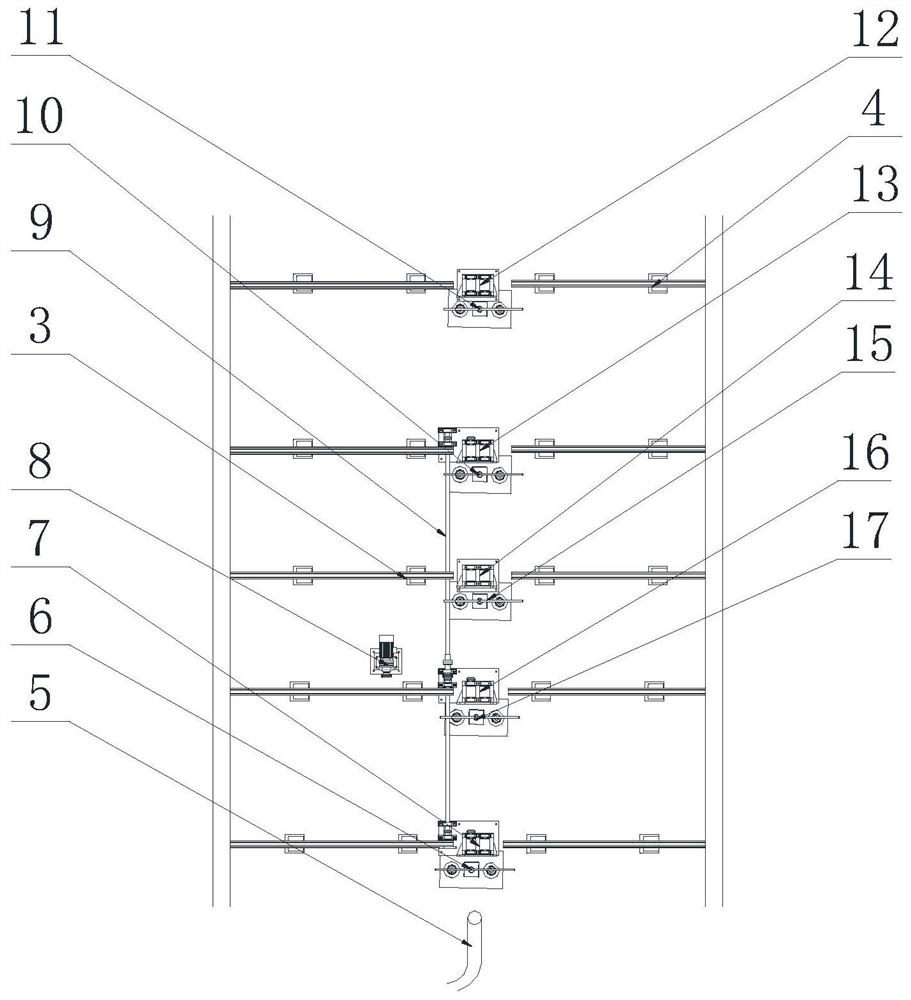

[0027] Pipe transfer mechanism, including the first cylinder turner 6, the second cylinder turner 17, the third cylinder turner 15, the fourth cylinder turner 10, the fifth cylinder turner 11, the first cylinder turner 1. The material turning device of the second cylinder, the material turning device of the third cylinder, the material turning device of the fourth cylinder, and the material turning device of the fifth cylinder are coaxially set at intervals corresponding to the length of the steel pipes.

[0028] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com