Energy absorption standard part, front longitudinal beam and manufacturing method of energy absorption standard part

A production method and technology of standard parts, which are applied in the directions of vehicle components, substructure, transportation and packaging, etc., can solve the problems of unstable collapse process, insufficient collapse, insufficient energy absorption, etc., so as to overcome the instability of the collapse process. , the effect of protecting the safety of the occupants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

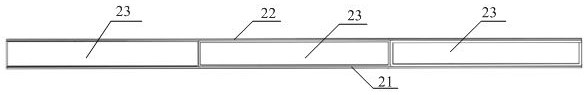

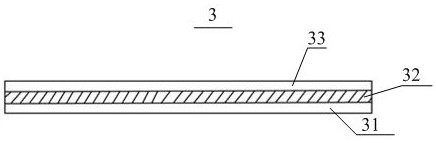

[0038] Such as Figure 1 to Figure 3 As shown, in Embodiment 1 of the present invention, a kind of energy-absorbing standard part provided, is used on the parts such as automobile front longitudinal beam, front beam, B-pillar, comprises:

[0039] The lower plate 21 is made of unidirectional non-woven carbon fiber cloth to realize one-way transmission of energy;

[0040] An upper plate 22 made of unidirectional non-woven carbon fiber cloth to realize one-way transmission of energy; and

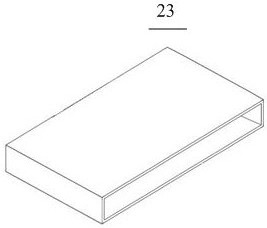

[0041] An intermediate structure 23 that is wound and solidified by orthogonal carbon fiber woven cloth to realize energy transmission in a three-dimensional direction. There is at least one intermediate structure 23, and each intermediate structure 23 is in the shape of a hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com