A municipal drainage ditch and its construction method

A drainage ditch and municipal technology, applied in waterway systems, water supply devices, sewer pipe systems, etc., can solve problems such as limited drainage capacity of gutters, impact on pedestrians and vehicles, and impact on the urban environment, so as to increase flood discharge capacity and reduce random drifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

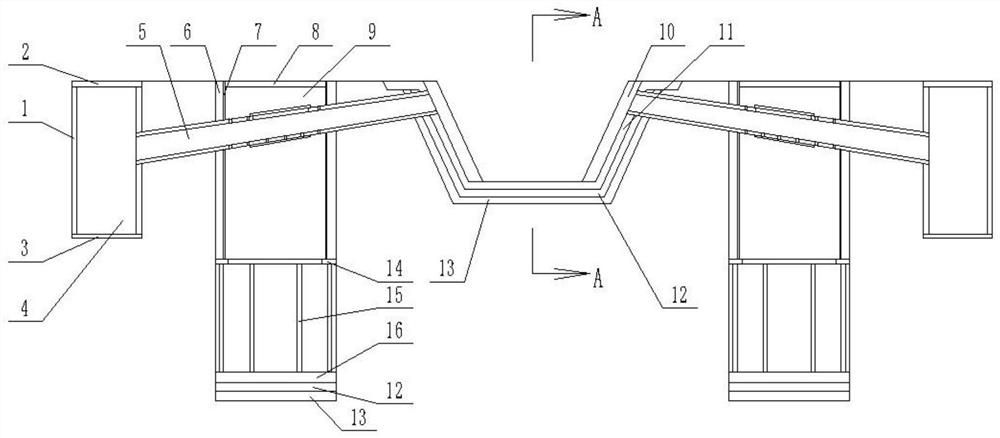

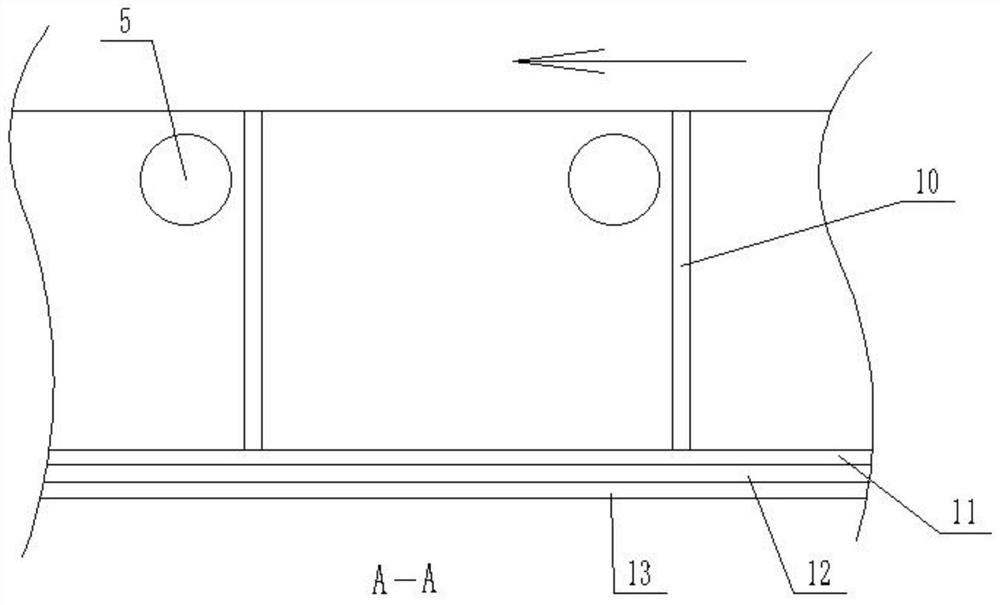

[0019] Specific implementation mode one: as Figure 1-Figure 4 As shown, this embodiment describes a municipal drainage ditch, including a ditch body; the municipal drainage ditch also includes a pipe 5, a masonry layer 6, a cement layer 7, a manhole cover II 8, a shaft II 9, and a cement cushion 11 , gravel layer 12, fine sand layer 13, annular backing plate 14, pillar 15, bottom plate II 16; the interior of the trench body is laid with fine sand layer 13, gravel layer 12, cement cushion 11 from bottom to top; The vertical shaft II9 is arranged on the side of the trench body, and the distance between the vertical shaft II9 and the trench body is 2-3m; the bottom plate II16 is fixedly arranged at the bottom of the vertical shaft II9, and the lower end of the bottom plate II16 is provided with a gravel layer 12 and a fine sand layer 13; The lower end of the pillar 15 is fixedly connected to the bottom plate II 16, and the upper end of the pillar 15 is fixedly connected to the...

specific Embodiment approach 2

[0020] Specific implementation mode two: as Figure 1-Figure 4 As shown, this embodiment is a further description of the first embodiment, and the depth of the shaft II9 is greater than twice the depth of the groove body. The rainwater can infiltrate into the deep soil faster, and the flood discharge capacity of the present invention is increased.

specific Embodiment approach 3

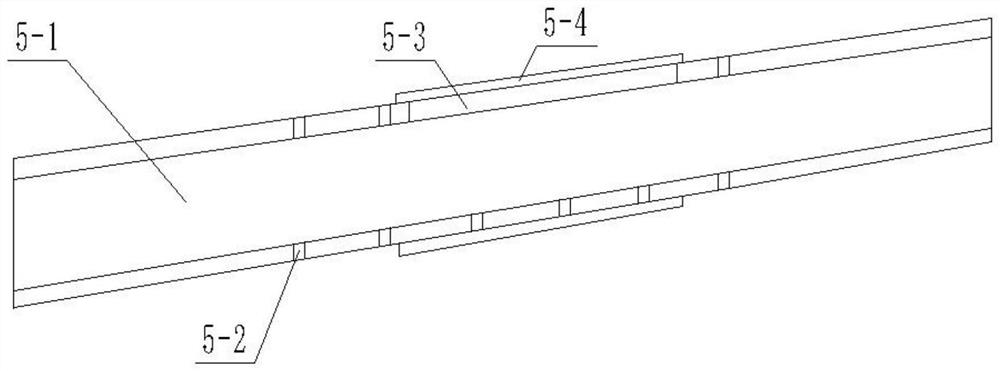

[0021] Specific implementation mode three: as Figure 1-Figure 4 As shown, this embodiment is a further description of specific embodiment 1. The pipe 5 includes a pipe main body 5-1; the middle position of the pipe main body 5-1 is provided with a plurality of penetrating pipe main body 5-1 wall thicknesses. The through hole 5-2; the through hole 5-2 is located in the shaft II9. It is used to drain the rainwater in the pipe 5 into the shaft II9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com