Electric floor mopping machine rotating speed control method, electric floor mopping machine and storage medium

A speed control, mopping technology, applied in electric speed/acceleration control, carpet cleaning, floor cleaning, etc., can solve problems such as throwing out and user trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

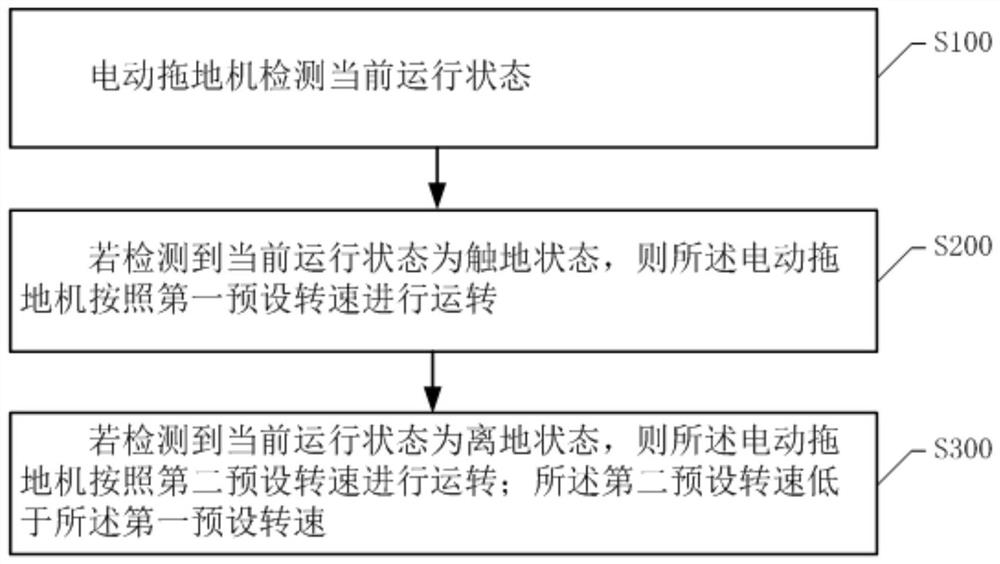

[0064] The method for controlling the speed of the electric mopping machine includes:

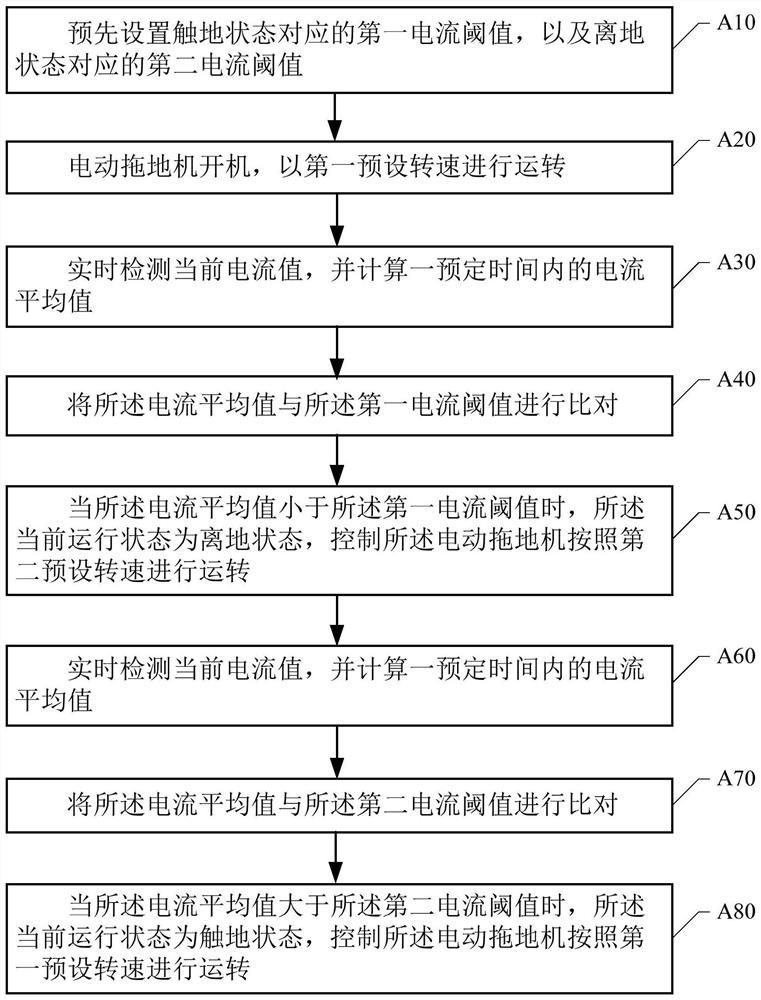

[0065] S1. Detect the current current value in real time, and calculate the average value of the current within a predetermined time;

[0066] S2. Comparing the average current value with the first current threshold;

[0067] S3. When the average current value is less than the first current threshold, the current running state is off the ground, and the electric mopping machine reduces the PWM duty cycle to a first preset value, according to the preset Running at low speed;

[0068] S4. Detect the current current value in real time, and calculate the average value of the current within a predetermined time;

[0069] S5. Comparing the average value of the current with the second current threshold;

[0070] S6. When the average value of the current is greater than the second current threshold, the current running state is the grounded state, and the electric mopping machine increases the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com