Equipment for manufacturing standard large-radius steel pipe bending product

A large-radius, steel pipe technology, applied in the field of equipment for preparing standard large-radius steel pipe bending products, can solve the problems of high labor intensity, hidden safety hazards, and large occupied area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

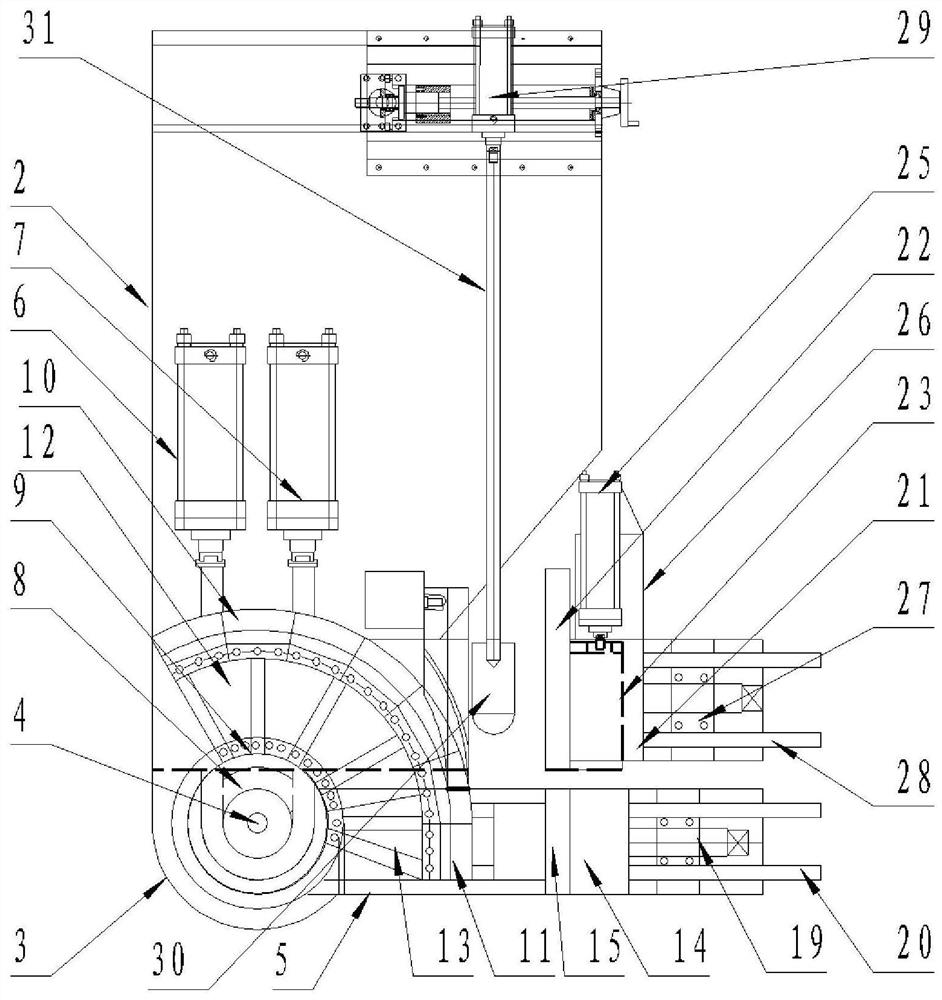

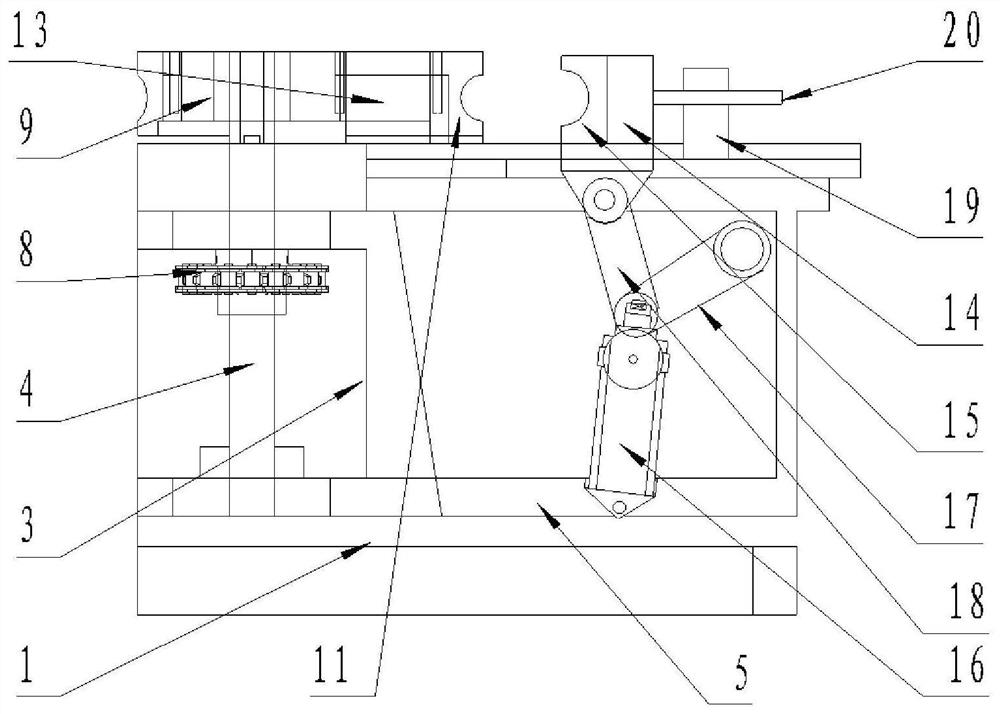

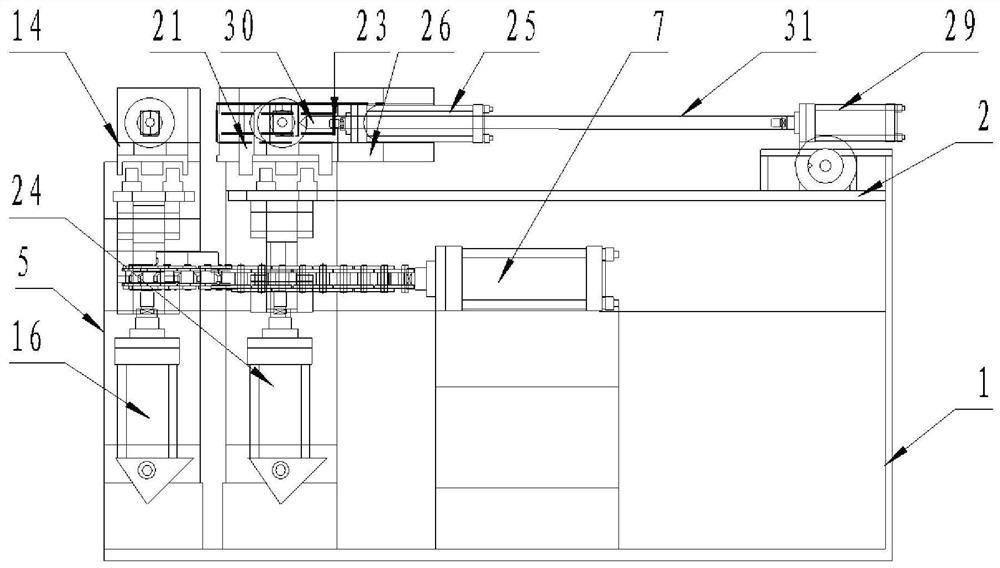

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a kind of equipment for preparing standard large-radius steel pipe bending products includes a strip frame 1 arranged horizontally at the front and back and a workbench 2 installed on the strip frame (the observer faces the invention and approaches the work The side of the table is the front side of the workbench, and the side away from the workbench is the back side of the workbench; the left side of the observer is the left side of the workbench, and the right side of the observer is the right side of the workbench), which is characterized by: A 1 / 4 concave hollow round table 3 is provided on the middle and upper part of the left front side elevation of the strip rack 1, and a main shaft 4 is vertically installed on the center of the hollow round table 3 using bearings with seats on both sides. The main shaft 4, which is vertically installed on the center position of the hollow round table 3...

Embodiment 2

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a kind of equipment for preparing standard large-radius steel pipe bending products includes a strip frame 1 arranged horizontally at the front and back and a workbench 2 installed on the strip frame (the observer faces the invention and approaches the work The side of the table is the front side of the workbench, and the side away from the workbench is the back side of the workbench; the left side of the observer is the left side of the workbench, and the right side of the observer is the right side of the workbench), which is characterized by: A 2 / 5 concave hollow round table 3 is provided on the middle and upper part of the left front side elevation of the strip rack 1, and a main shaft 4 is vertically installed on the center of the hollow round table 3 using bearings on both sides of a main shaft 4 respectively. The main shaft 4, which is vertically installed on the center position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com