Stainless steel disc polishing equipment

A stainless steel plate and equipment technology, which is applied in grinding/polishing equipment, metal processing equipment, surface polishing machine tools, etc., can solve the problems of hand injury and labor, and achieve the effect of avoiding hand injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

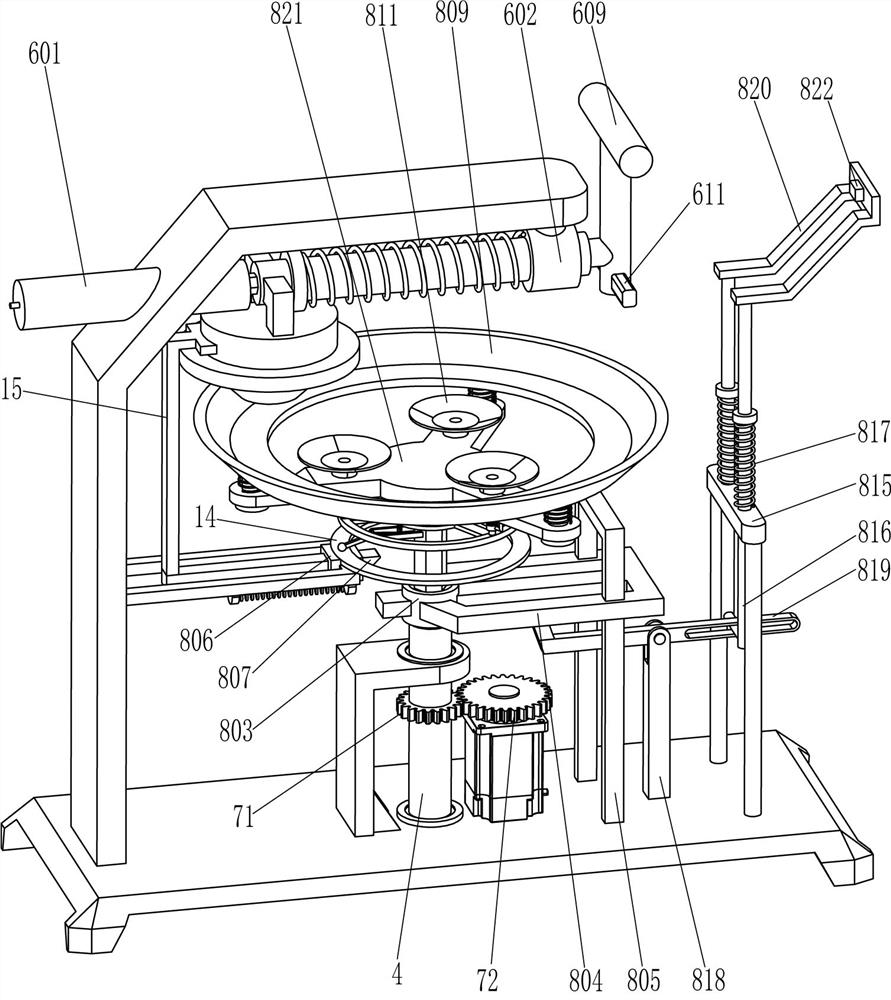

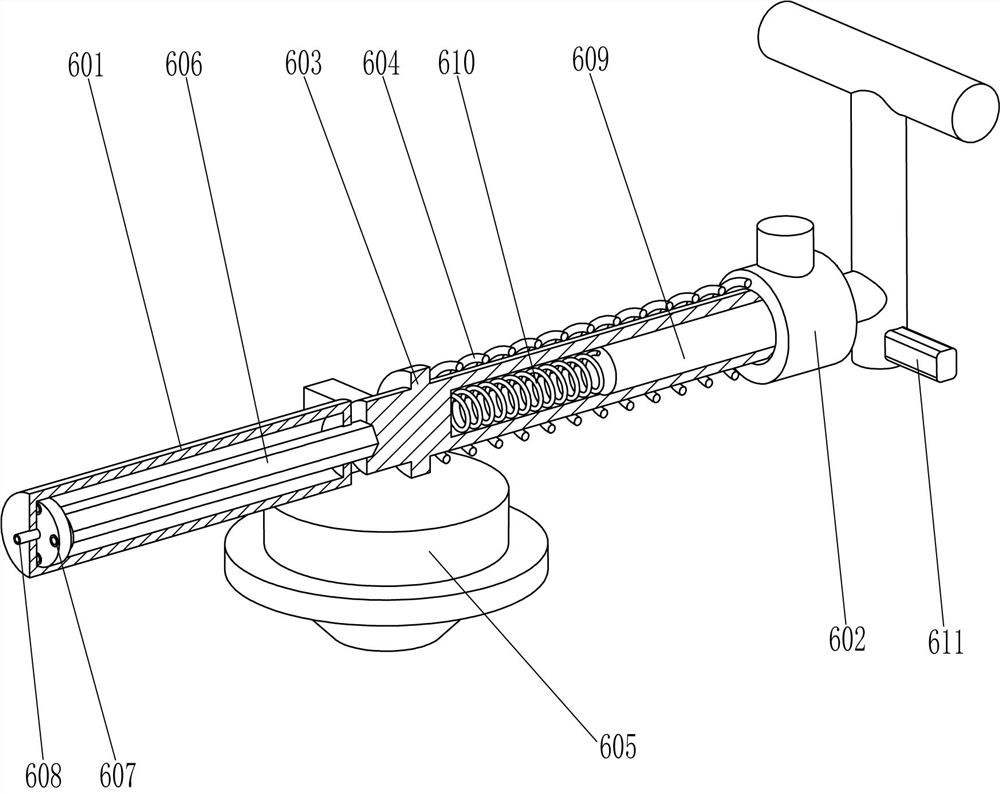

[0023] A stainless steel disc polishing equipment, such as Figure 1-Figure 5 As shown, it includes a base plate 1, a servo motor 2, a support plate 3, a hollow shaft 4, a frame 5, a polishing assembly 6, a spline shaft 7, a first gear 71, a second gear 72 and a rotating assembly 8, and the top of the base plate 1 The left side is fixed with a frame 5, the upper part of the frame 5 is provided with a polishing assembly 6, the top of the bottom plate 1 is connected with a hollow shaft 4 in the middle of the rotation type, and the hollow shaft 4 is slidingly provided with a spline shaft 7, a spline shaft 7 There is a rotating assembly 8 between the top right side of the bottom plate 1, and the rotating assembly 8 cooperates with the polishing assembly 6. The support plate 3 is fixed in the middle of the top left side of the bottom plate 1, and the upper right side of the support plate 3 is rotated with the outer upper part of the hollow shaft 4. connection, the outer middle part...

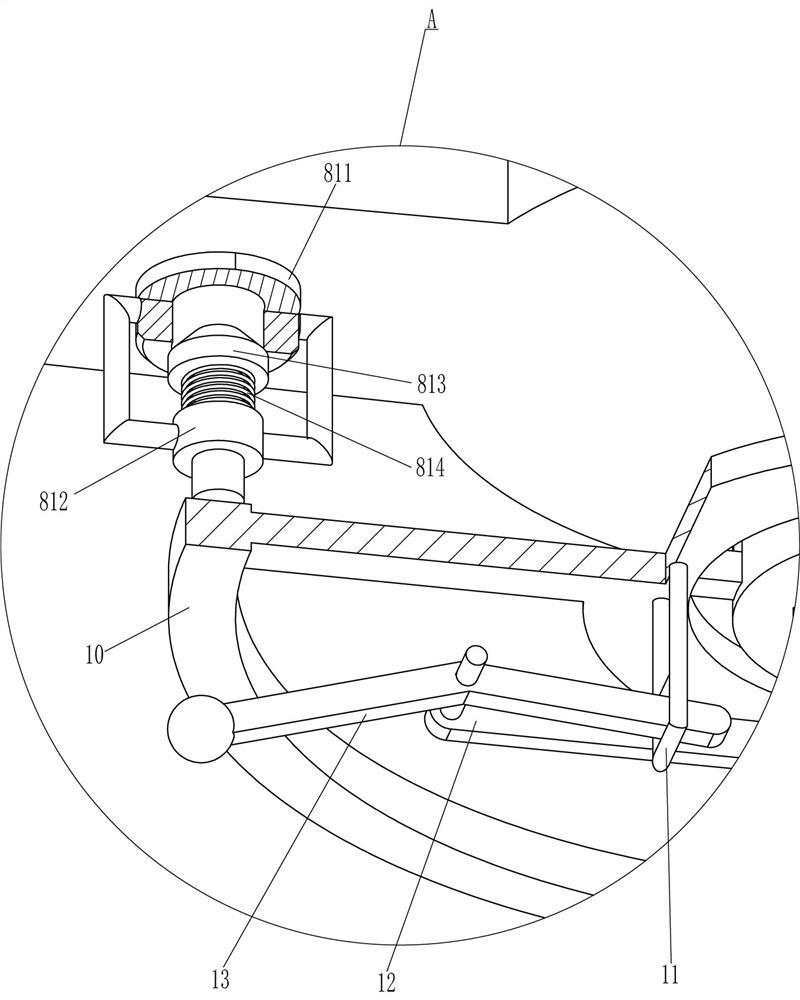

Embodiment 2

[0030] On the basis of Example 1, such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, it also includes a sliding frame 10, a fixed rod 11, a support rod 12, a special-shaped rotating rod 13, a fixed ring 14 and a guide sleeve 141. A sliding frame 10 is provided for the sliding type between the circumferential directions. The top of the sliding frame 10 is fixedly connected to the bottom end of the sealing rod 813 in the circumferential direction. The top of the guide sleeve 806 is fixedly connected with a fixed ring 14. 10 is fixedly connected with a fixed rod 11 in the middle on the left side of the bottom, and is fixedly connected with two support rods 12 on the left side of the upper part of the spline shaft 7. Rotating type is connected with special-shaped rotating rod 13 between the sides, and special-shaped rotating rod 13 left ends contact and cooperate with fixed ring 14 tops, and special-shaped rotating rod 13 right-hand ends pass fixed rod 11 bottoms ...

Embodiment 3

[0033] On the basis of embodiment 1 and embodiment 2, such as figure 1 and figure 2 As shown, it also includes a contact rod 15, the top left side of the wedge-shaped rod 807 is fixedly connected with the contact rod 15, and the right end of the contact rod 15 contacts and cooperates with the left side of the grinding block 605.

[0034]Initially, the third spring 808 is in a stretched state. When the operator pulls the pull rod 609 to move to the right, the grinding block 605 moves to the right and breaks away from the contact rod 15. Due to the action of the third spring 808, the wedge-shaped rod 807 moves to the right to drive The contact lever 15 moves to the right to a suitable position. When the grinding block 605 moves to the left and resets, it means that the stainless steel disc is polished. The grinding block 605 resets to drive the contact rod 15 to move to the left to reset, and the contact rod 15 moves to the left to drive the wedge-shaped rod 807 to move to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com