An integrated propulsion device and its construction method

A propulsion device and an integrated technology, applied in vertical shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of large occupied area of continuous pipe jacking devices and complex equipment structure, etc., to facilitate the installation of pipeline operations, increase the propulsion speed, The ingenious effect of the overall structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

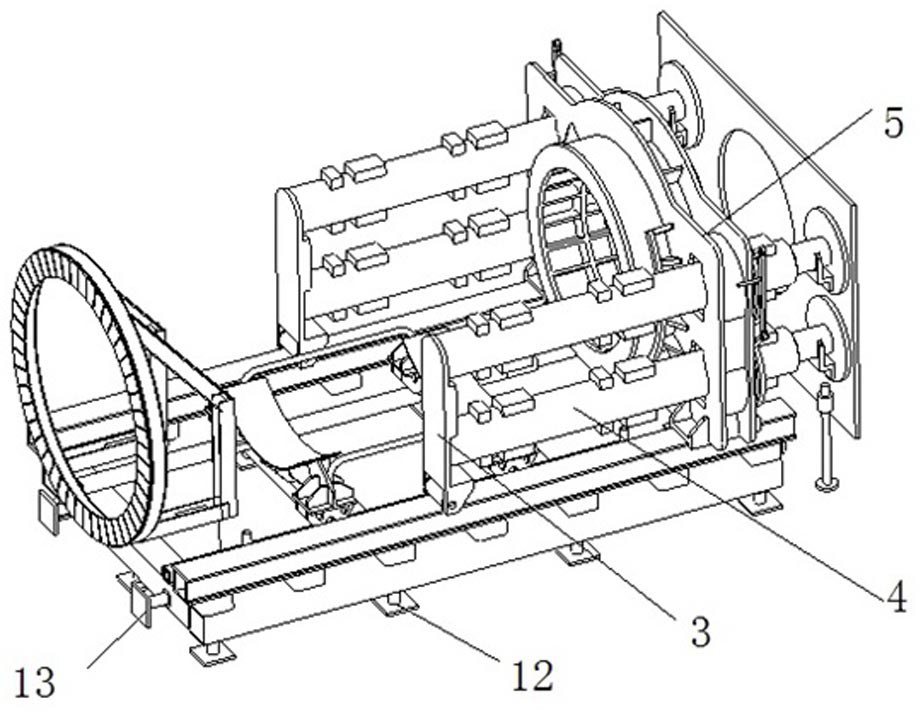

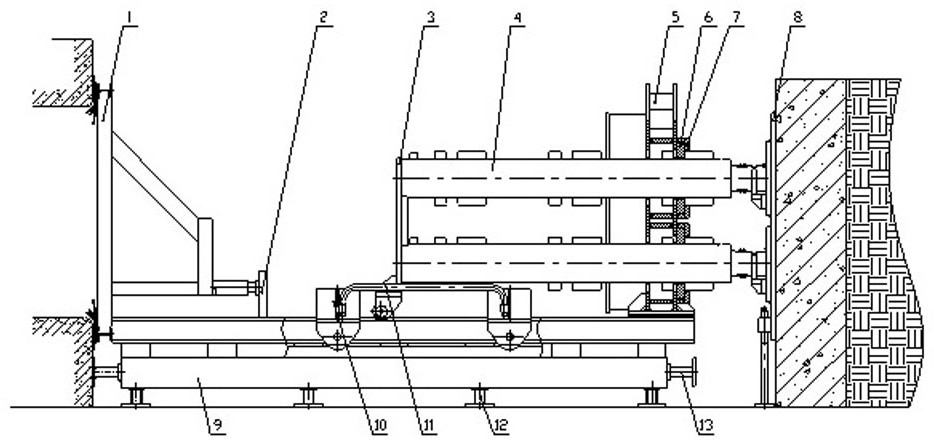

[0043] Embodiment 1: as figure 1 As shown, an integrated propulsion device includes a door sealing assembly, a pipe joint transport assembly and a back wall, and the hole sealing assembly and the pipe joint transport The propulsion platform assembly is slidingly arranged on the frame assembly, and the propulsion platform assembly is connected with the back wall 8, and the propulsion platform assembly, the hole sealing assembly, and the pipe joint transport trolley assembly are integrated into the bottom frame assembly. On the whole, it is an integrated device, which greatly reduces the occupied space of the device. It is suitable for the continuous pushing operation of pipe joints in a small space. Change steps, increase the stroke of the propulsion platform, and realize the large displacement under the short cylinder stroke, thereby reducing the size of the launch shaft.

[0044] Such as figure 2 As shown, the underframe assembly includes an underframe 9, on which slide r...

Embodiment 2

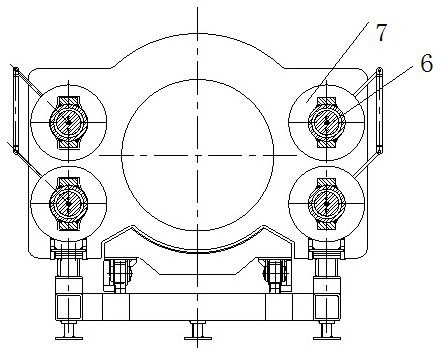

[0052] Embodiment 2: as Figure 2~4 As shown, an integrated propulsion device, the number of the rotating baffles 6 is at least four groups, the four groups of rotating baffles 6 are symmetrically arranged in the propulsion platform 5, and the two groups of rotating baffles on each side form a group The rotating wheel group is that two groups of rotating baffles 6 on each side on the same vertical line form a rotating wheel group, by dividing the four groups of rotating baffles into two groups of rotating wheels in the vertical direction, and the corresponding two groups of rotating baffles The plate 6 is connected with the drive rod and the guide rod to form a four-bar mechanism as a whole, and two sets of four-bar mechanisms are formed as a whole. The two sets of drive rods are used to drive two sets of rotating wheels respectively, so that four sets of rotating baffles can be rotated around the center line of the cylinder. After the rotating baffle rotates at a certain angl...

Embodiment 3

[0054] Embodiment 3: as Figure 5 As shown, an integrated propulsion device, the number of the rotating baffles 6 is at least four groups, the four groups of rotating baffles 6 are symmetrically arranged in the propulsion platform 5 and the rotating baffles 6 are all provided with gear teeth, The two sets of rotating baffles on each side are meshed to form a set of rotating wheels, and one set of rotating baffles in the two sets of rotating wheels is connected by a drive rod and a guide rod to form a four-bar mechanism as a whole, and the four-bar mechanism is driven by the drive rod. The two sets of rotating baffles drive the respective meshing rotating baffles to realize the synchronous rotation of the four sets of rotating baffles. The overall structural design is ingenious, reducing the installation of redundant driving equipment and making the overall light weight of the device.

[0055] All the other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com