Line rail frog wear inspection ruler

A technology for rails and frogs, which is applied in the field of rail frog wear inspection and line rail frog wear inspection ruler. , Frequent adjustment of measuring claws and other problems, to achieve the effect of improving service life, efficient and convenient adjustment process, and good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

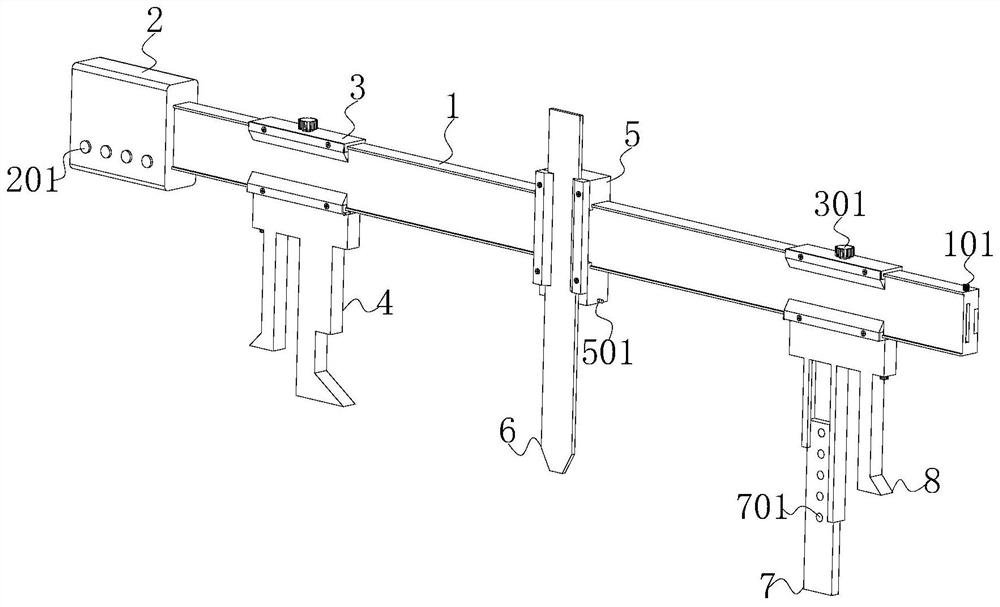

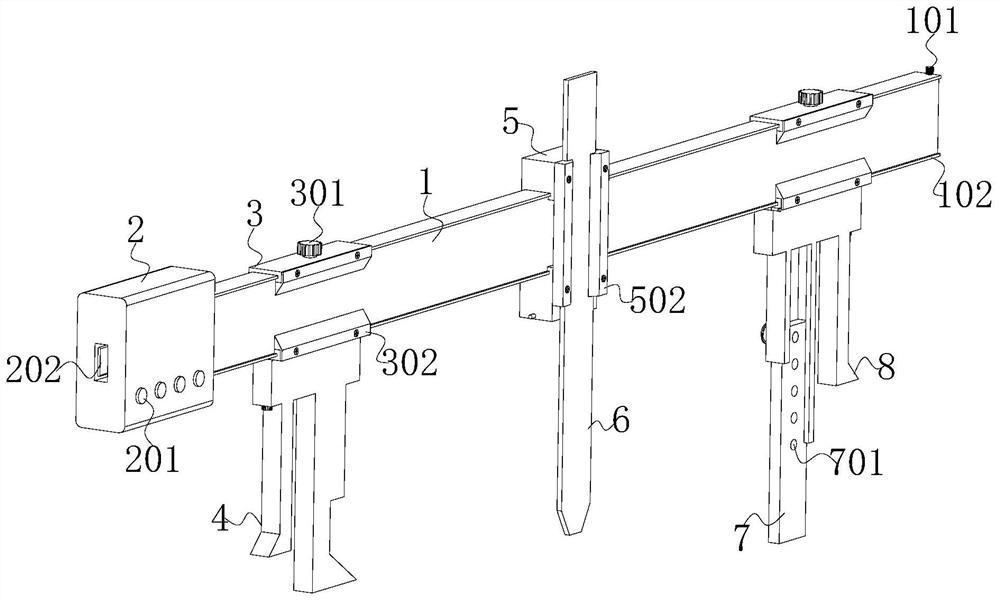

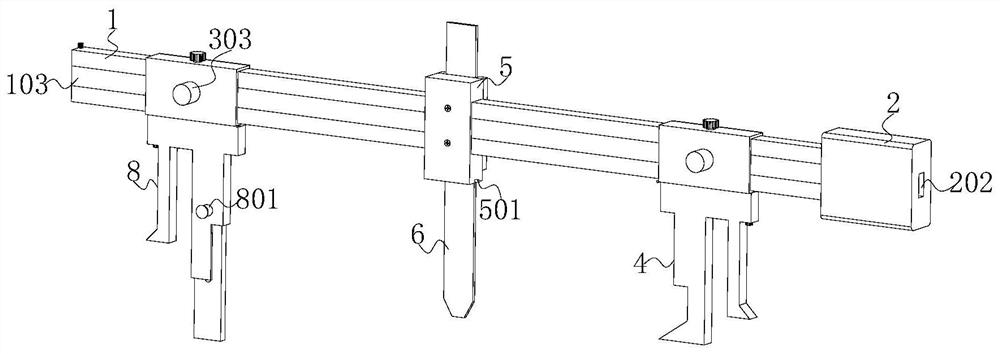

[0057] see Figure 1-3 As shown, the present invention is a line rail frog wear inspection ruler, including a ruler plate 1, a control box 2, a first adjustment frame 3 and a second adjustment frame 5, and the middle part of the ruler plate 1 is fixedly fitted with a second adjustment frame 5, The first adjustment frame 3 is fitted with a symmetrical sliding fit on the ruler plate 1 on both sides of the second adjustment frame 5; the control box 2 is fixedly connected to one end surface of the ruler plate 1, as can be seen from the accompanying drawings, the above-mentioned components constitute the device. basic component;

[0058] Wherein, the bottom surfaces of the two first adjusting frames 3 are respectively fixedly fitted with a first measuring frame 4 and a second measuring frame 8, and the second adjusting frame 5 is equipped with a first measuring ruler 6, and the first measuring ruler 6 is Frog center vertical wear gauge.

[0059] see Figure 4 , 5 , 11 and 12, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com