Patents

Literature

56results about How to "Fast positioning and fixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device for high-efficiency grafting of Chinese torreya

InactiveCN108575369ANot prone to crackingConducive to survivalGraftingAgricultural engineeringTorreya

The application of the invention belongs to the technical field of plant grafting equipment and particularly discloses a device for high-efficiency grafting of Chinese torreya. The device comprises asupporting rod, a first clamping sleeve, a second clamping sleeve, a supporting rod, a first supporting rod, a second supporting rod, a cross plate, a top plate, a cutter, a bisynchronous motor, a first gear, a first sleeve and a first cross rod, wherein a first vertical shaft is arranged on the first cross rod and is connected with a through groove in a sliding manner; a second sleeve coaxial tothe first sleeve is arranged at the lower end of the cross plate and is rotatably connected with the cross plate; convex teeth are arranged on the inner wall of the second sleeve along the circumferential direction; the first gear can be meshed with the convex teeth in the first sleeve and the second sleeve; a horizontal second cross rod is arranged on the second sleeve; one end of the second cross rod, away from the second sleeve, is provided with a second vertical shaft in a rotary connection manner; the second vertical shaft is provided with a thin film reel. The device is mainly used for grafting the Chinese torreya, and the problem of low grafting efficiency due to more operation steps in the grafting process is solved.

Owner:GUIZHOU WUCHUAN WANNIANFENG AGRI DEV CO LTD

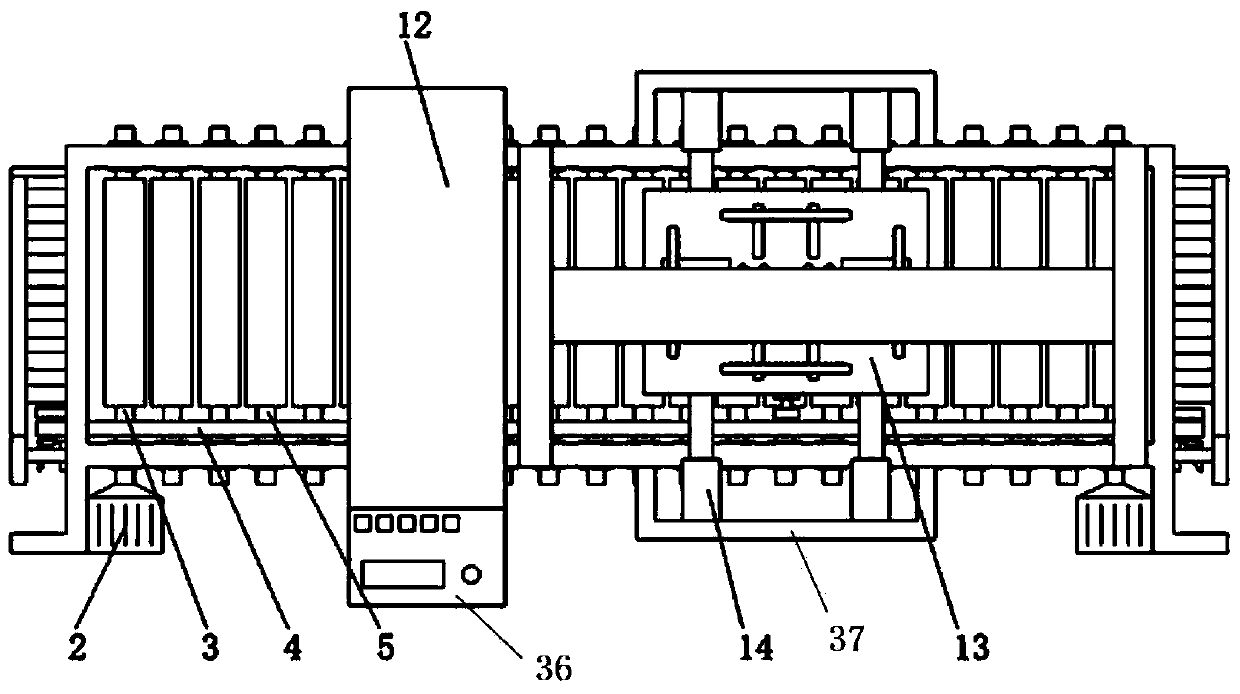

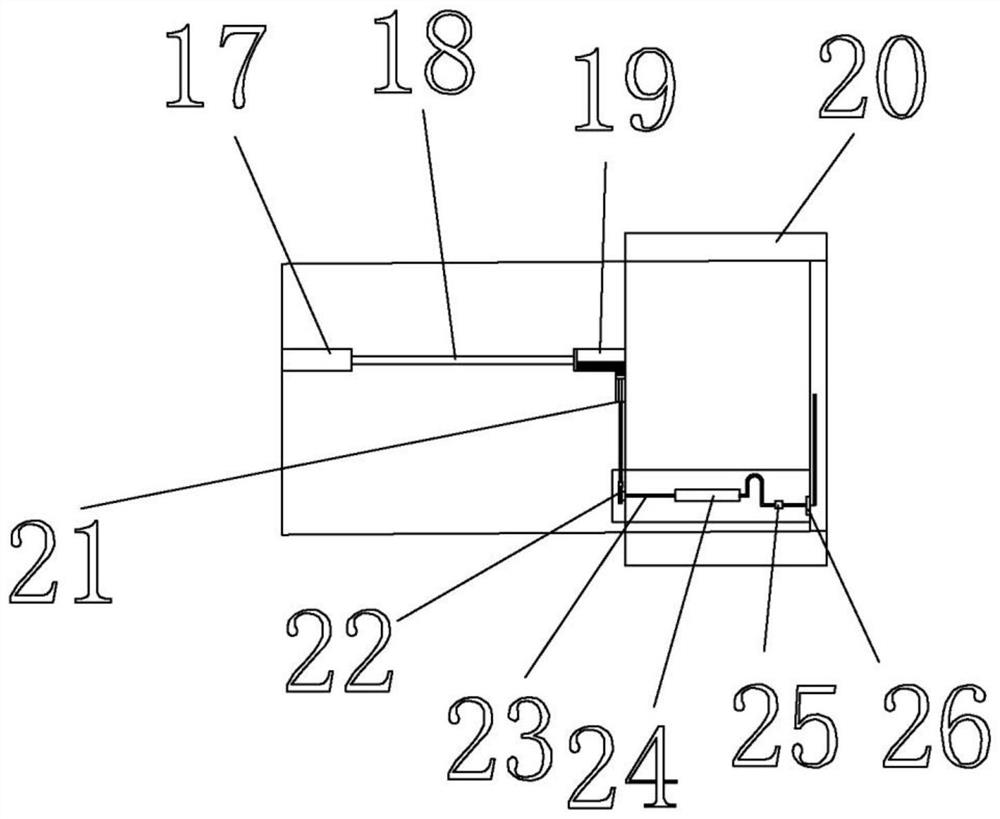

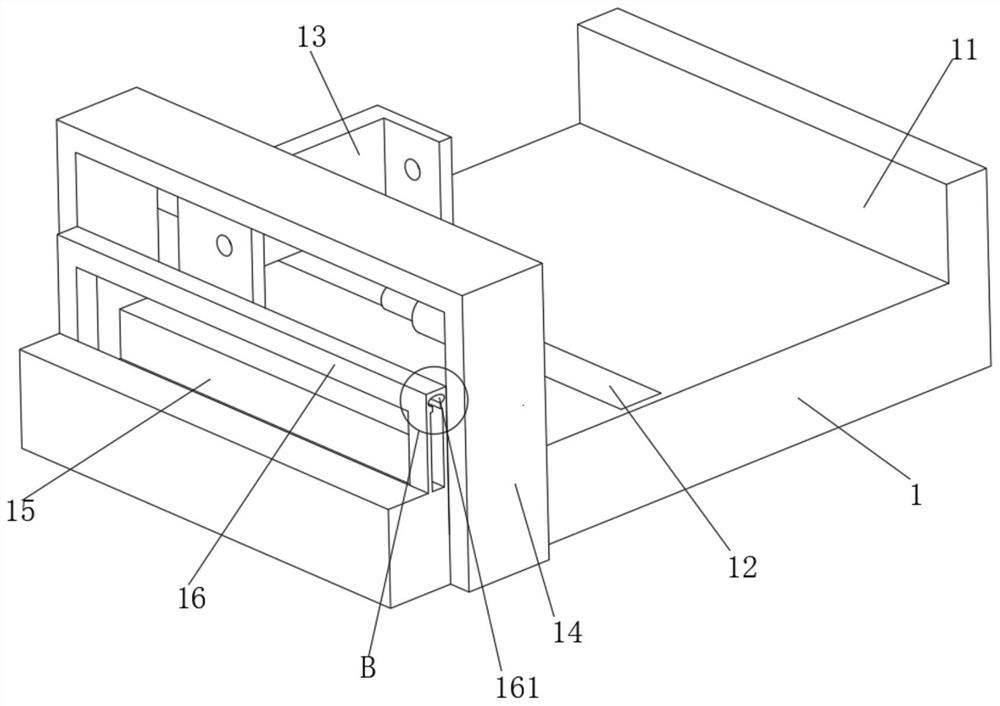

Electric integration box bundling and packing device for logistics transportation

ActiveCN110861810AFast positioning and fixingEasy to fixWrapping material feeding apparatusWeb rotation wrappingLogistics managementElectric machine

Owner:CHINA THREE GORGES UNIV

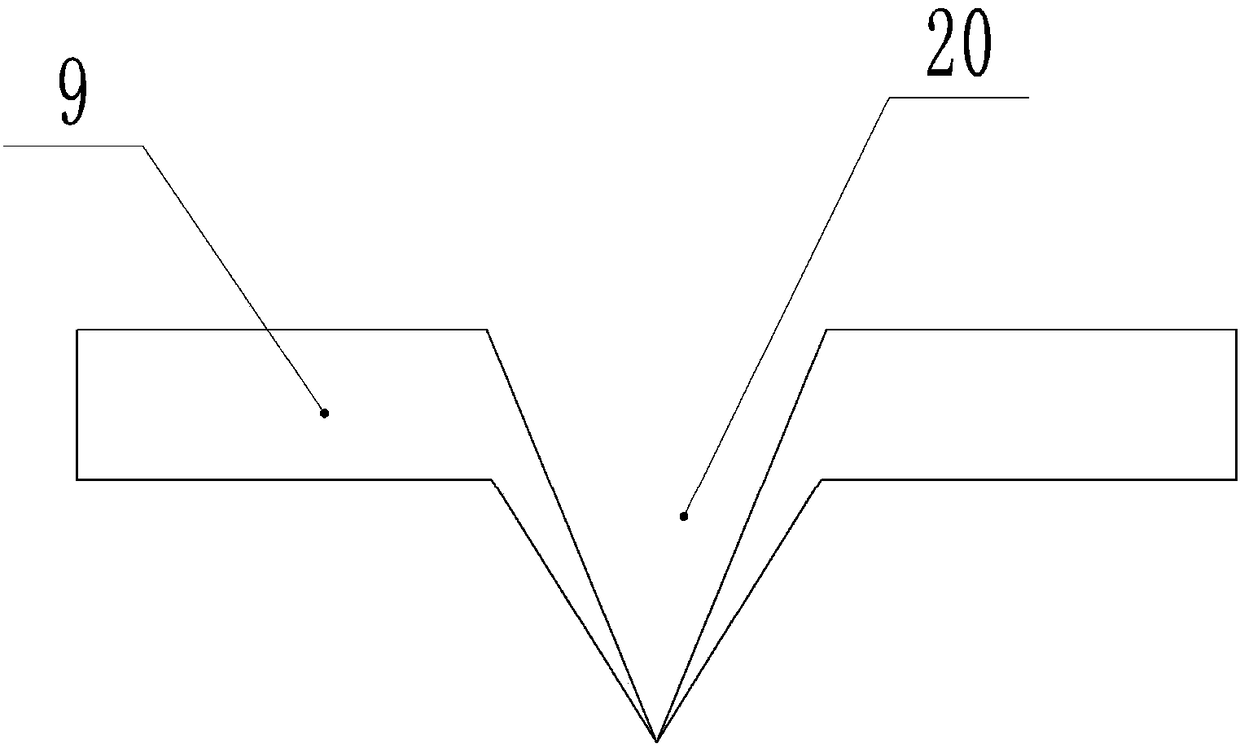

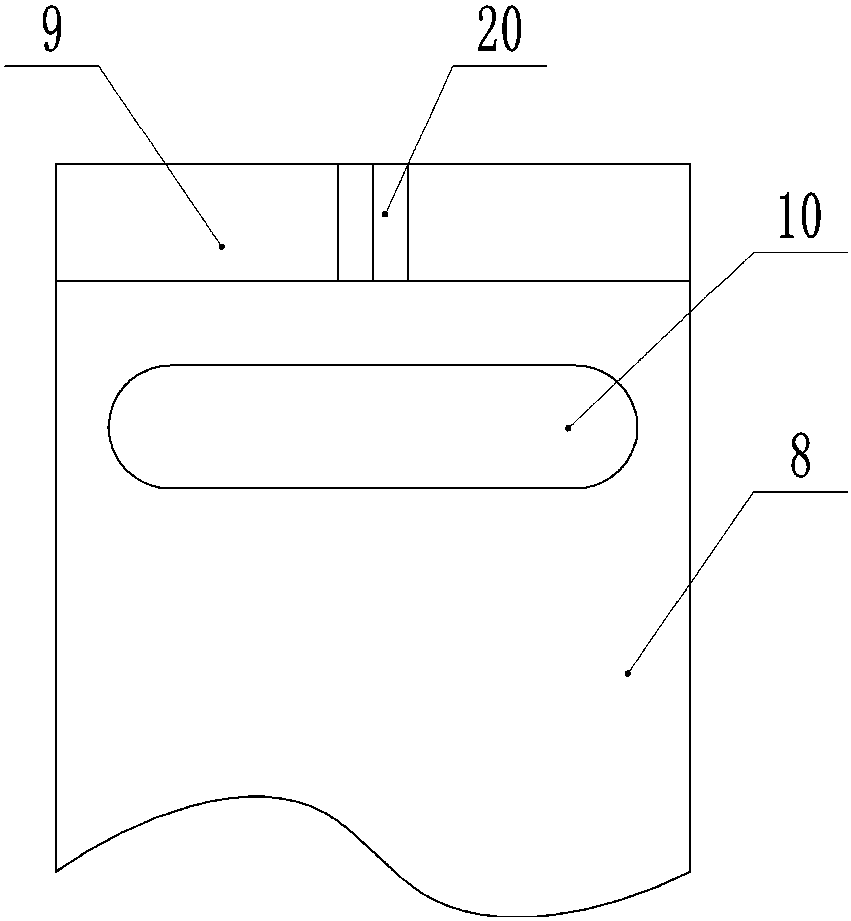

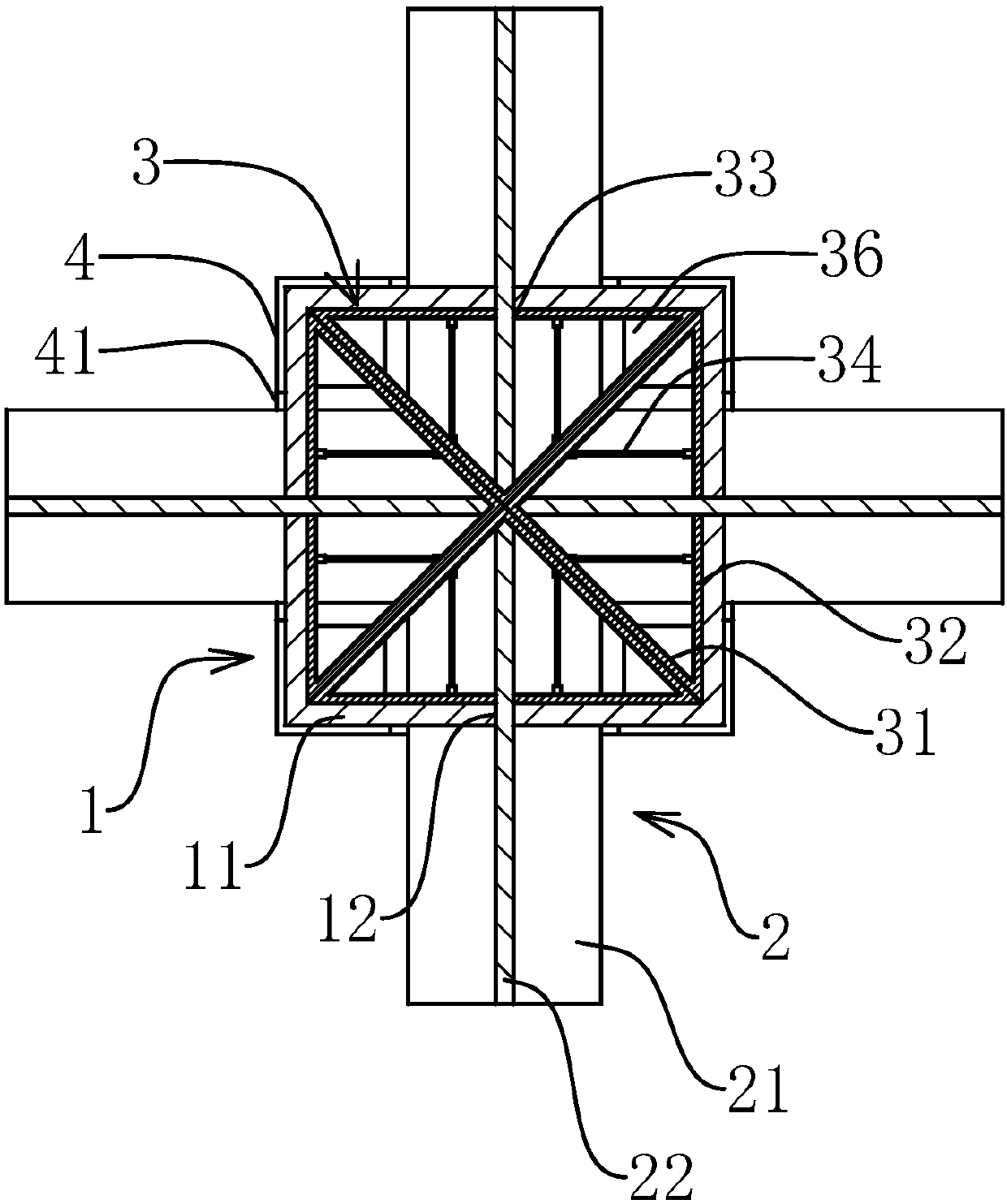

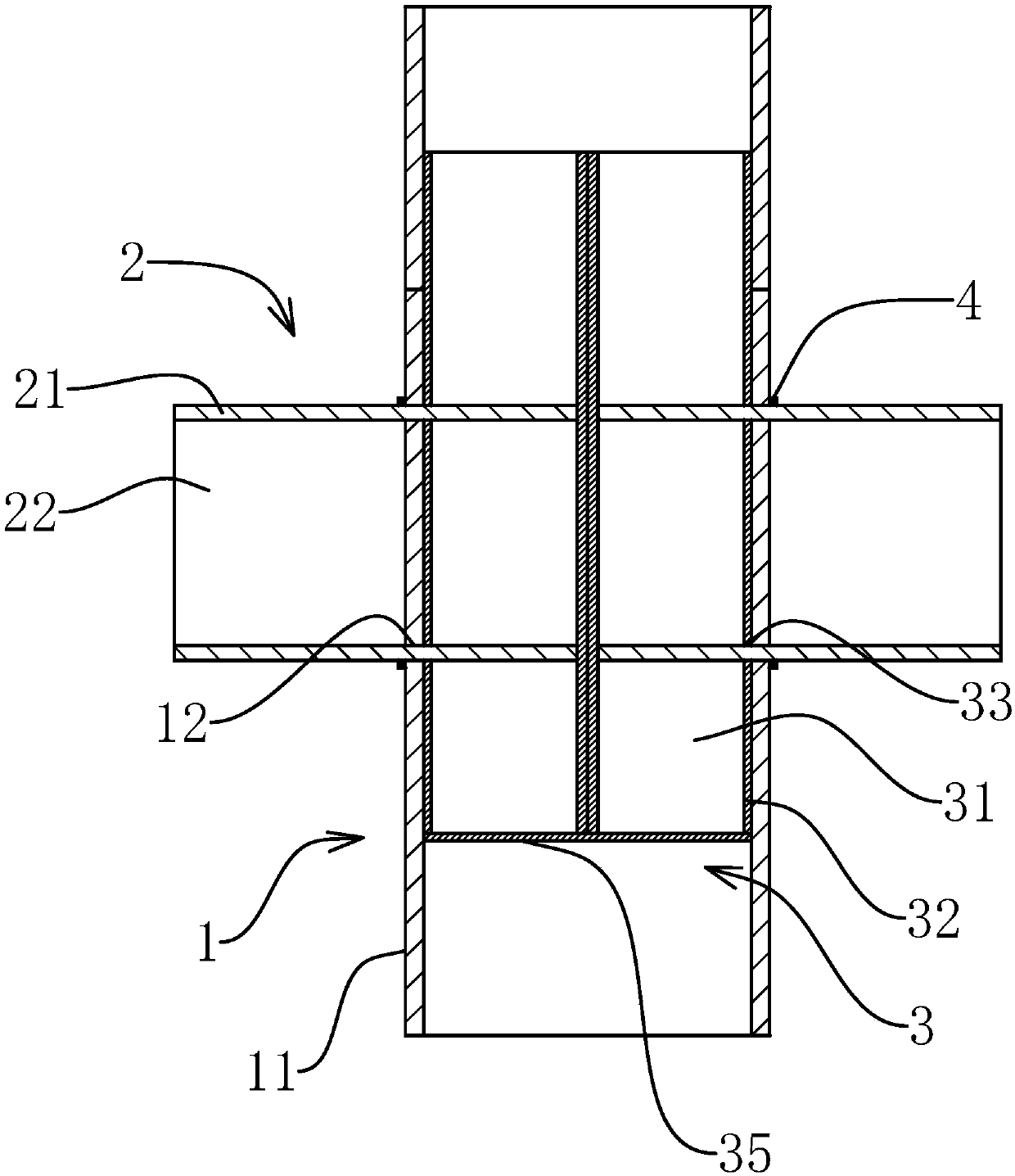

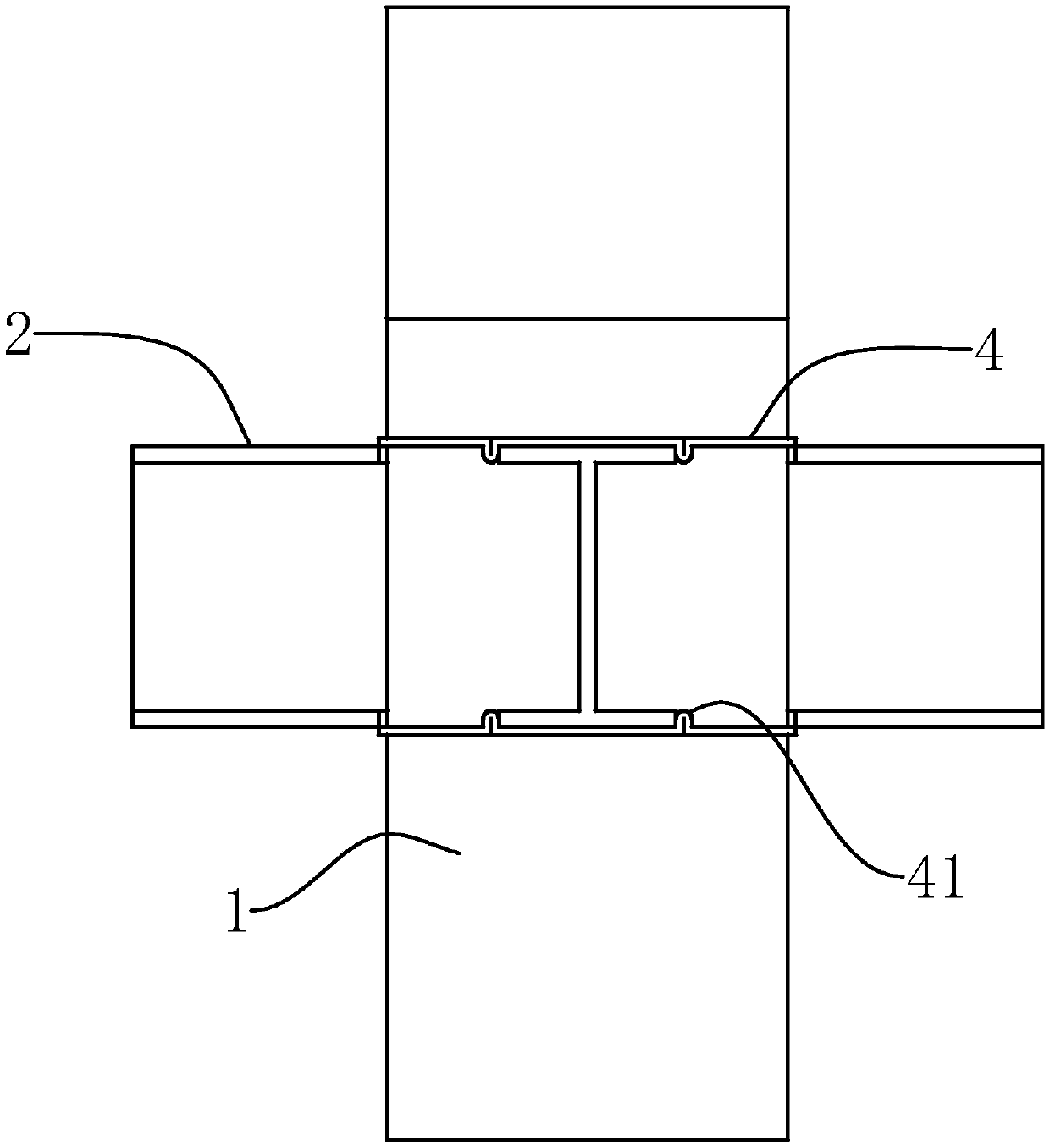

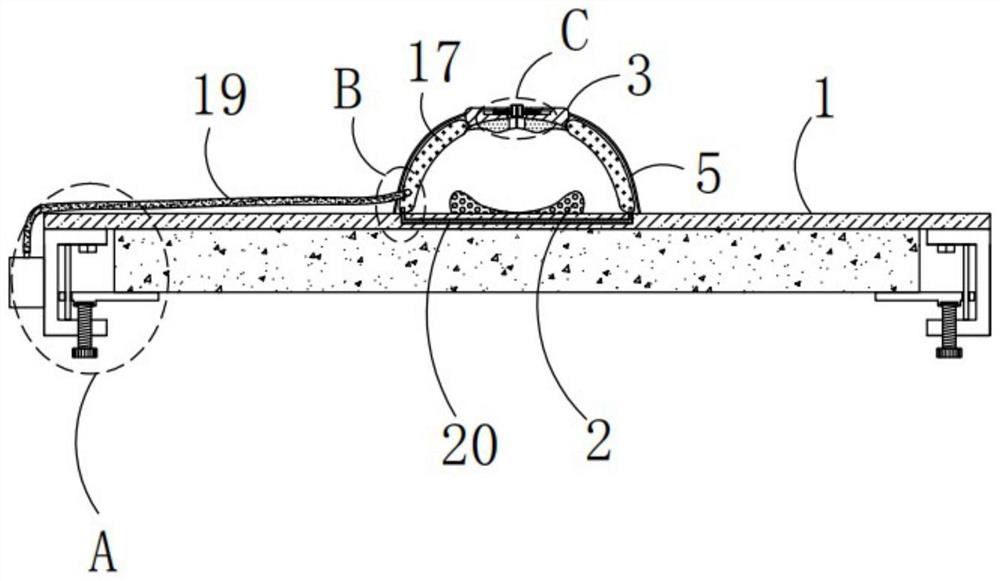

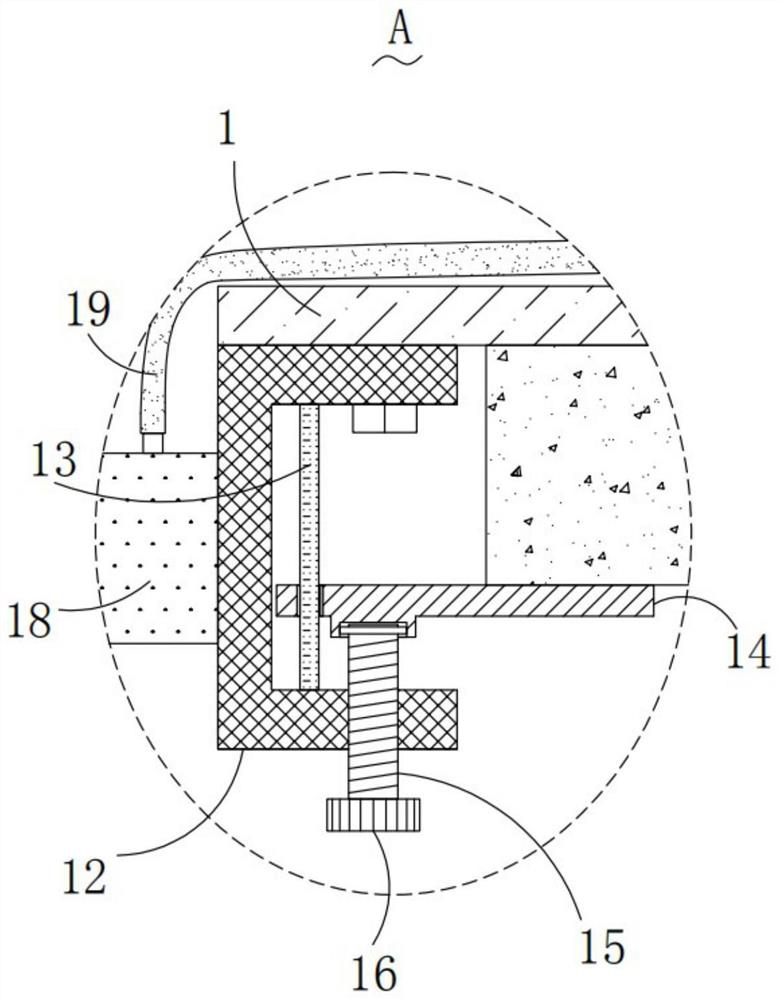

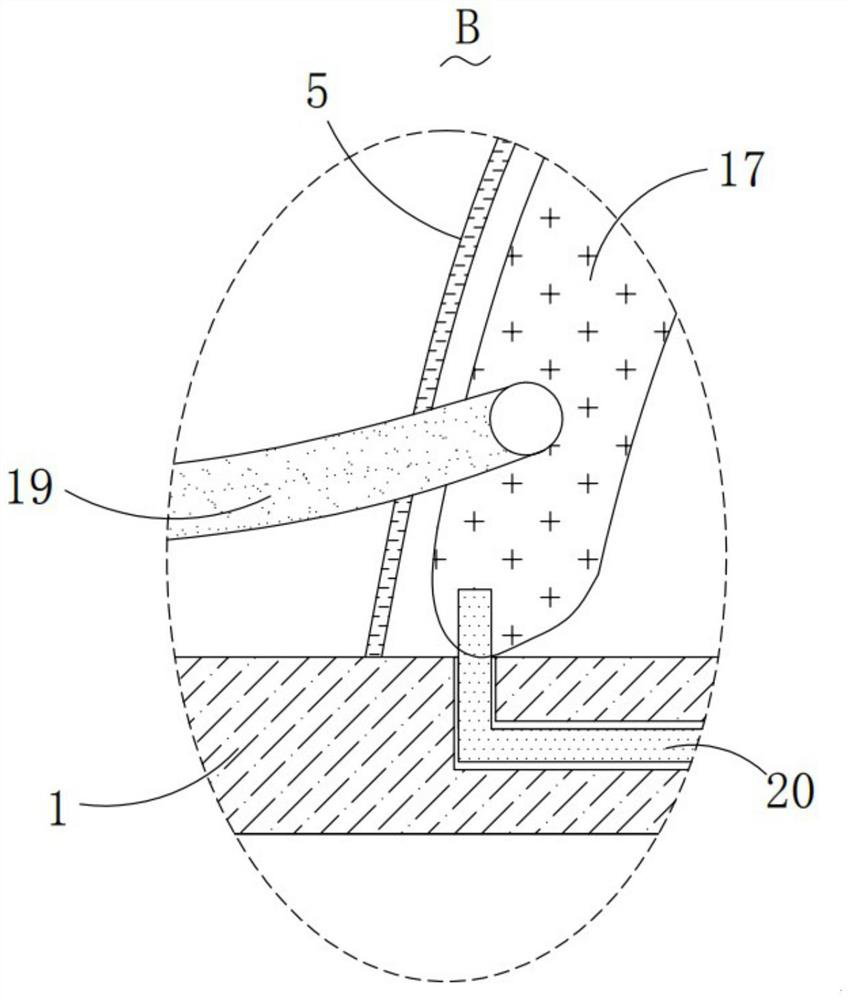

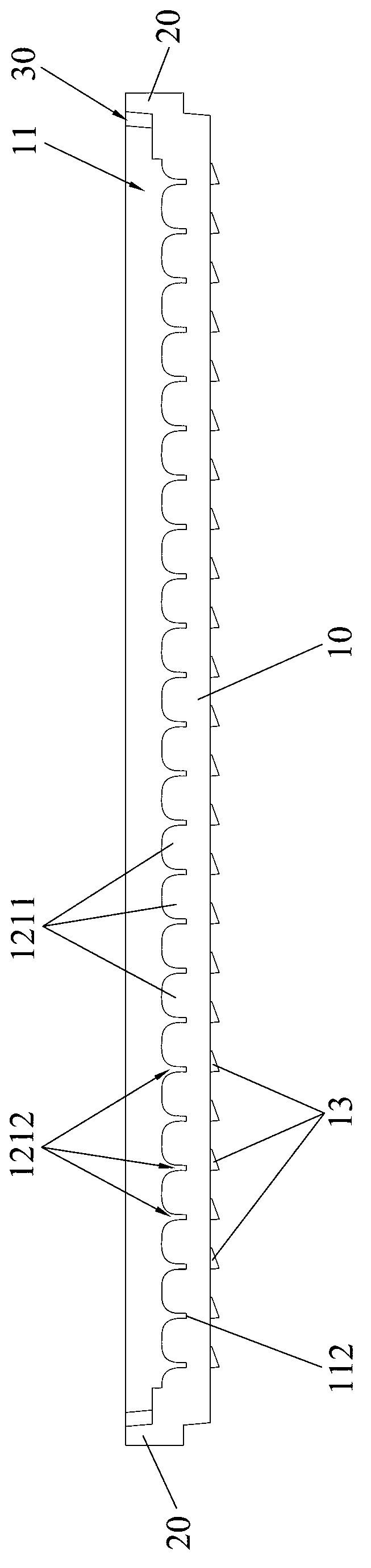

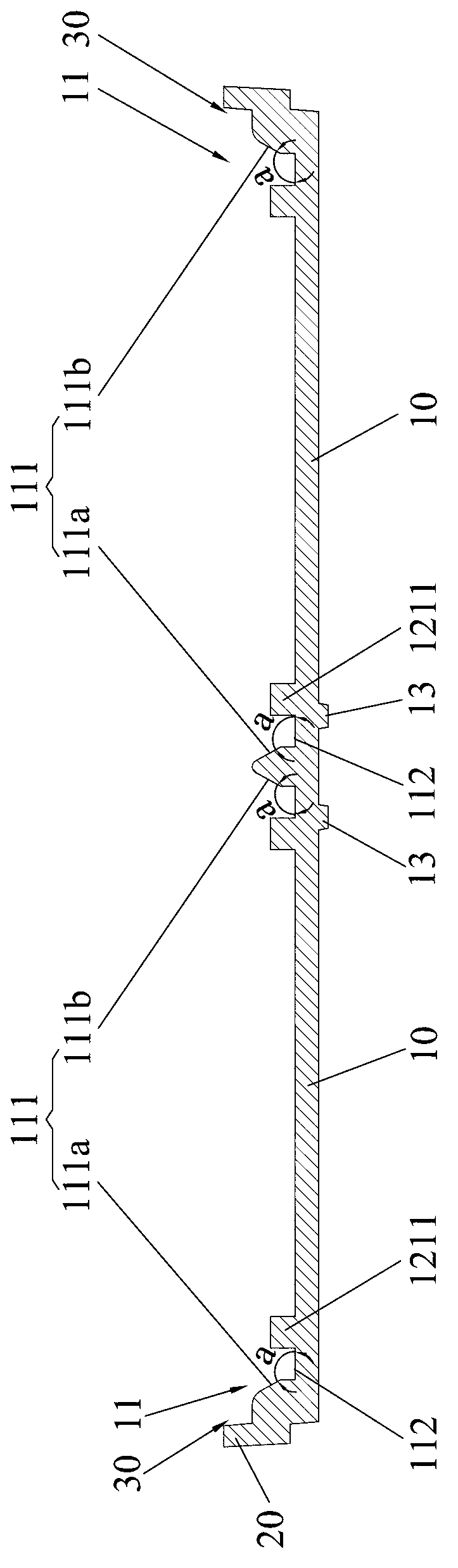

Internal reinforcing type beam column joint and mounting method thereof

InactiveCN107675804AFast positioning and fixingQuick reinforcement installationBuilding constructionsPlate columnEngineering

The invention provides an internal reinforcing type beam column joint and a mounting method thereof, and belongs to the field of building structures. According to the internal reinforcing type beam column joint and the mounting method thereof, the problem that an existing beam column joint is low in construction efficiency and strength is solved. The internal reinforcing type beam column joint comprises column bodies and beam bodies, the column bodies comprise column plates, each beam body comprises wing plates and web plates, and the end parts of the two wing plates form a V shape; a joint located in each column body is further included; each joint comprises four triangular tubular connecting tubes, and each connecting tube comprises two reinforcing plates and connecting plates; a squaretube shape is formed by surrounding of the four connecting plates, and the four connecting tubes are embedded in the column bodies; the outer side faces of the connecting plates and the inner side faces of the column plates are fixed; external perforations and internal perforations are formed in the column plates and the connecting plates, and the beam bodies penetrate into the external perforations and the internal perforations; the end parts of the wing plates are welded to the inner side faces of the reinforcing plates, and the two column bodies are connected in an aligning mode; and the top ends of the connecting tubes extend out of the top ends of the column bodies and are embedded in the column body located on the upper part, and the connecting plates are connected with the column plates through fasteners. The internal reinforcing type beam column joint cleverly utilizes the four connecting tubes to rapidly reinforce and install the beam bodies and the column bodies.

Owner:WENZHOU OULIN ELECTRONICS TECH CO LTD

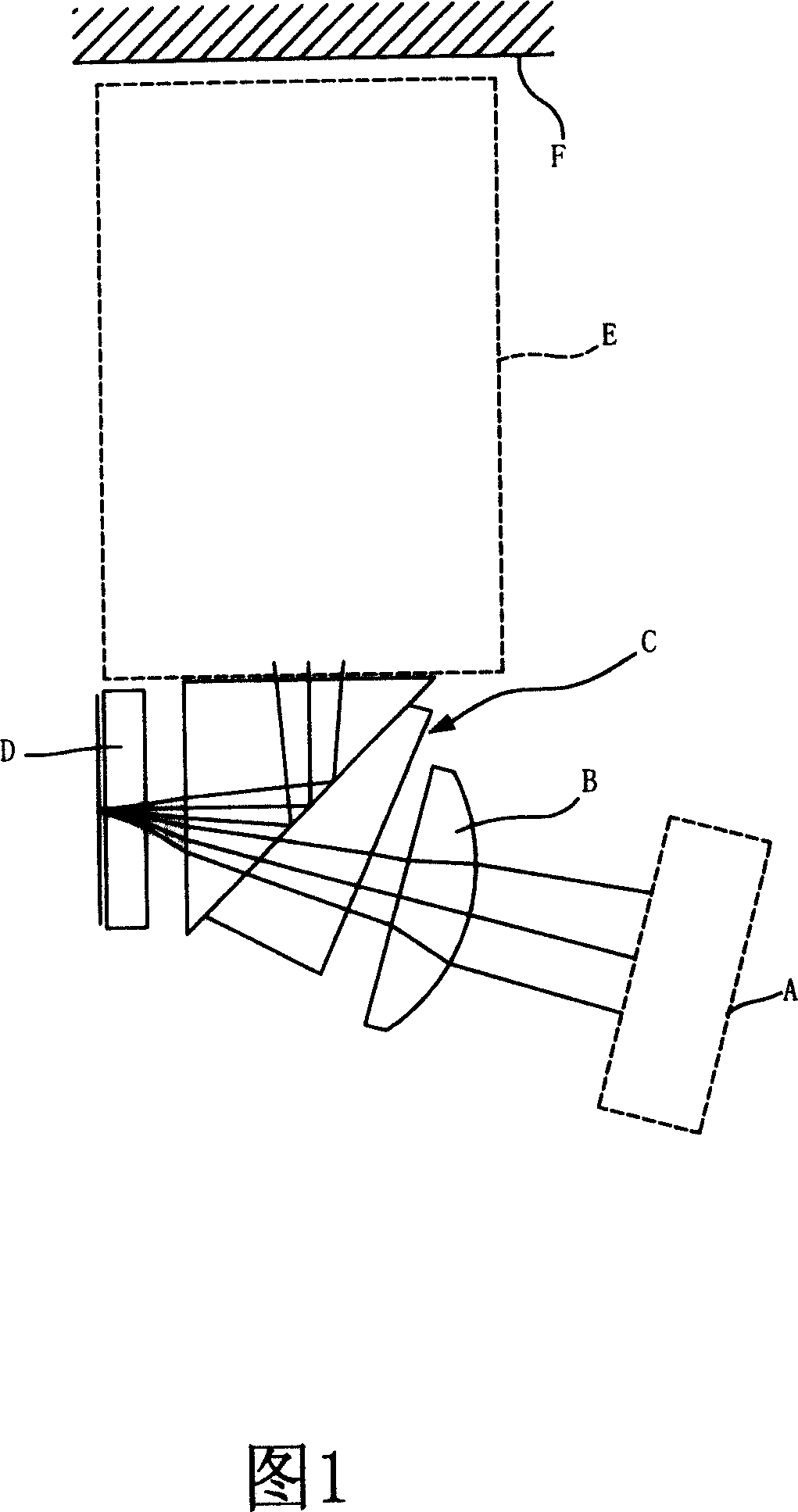

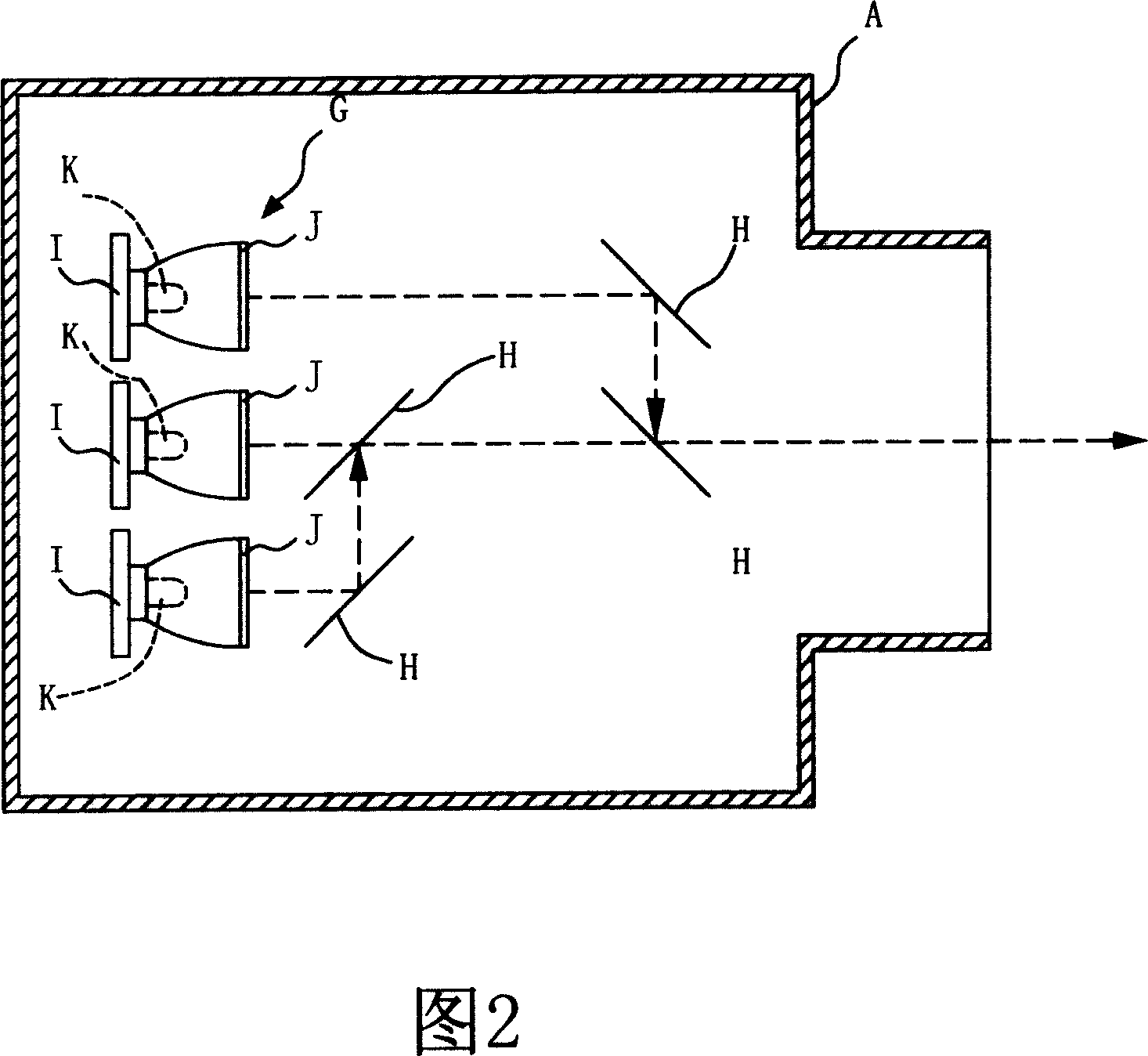

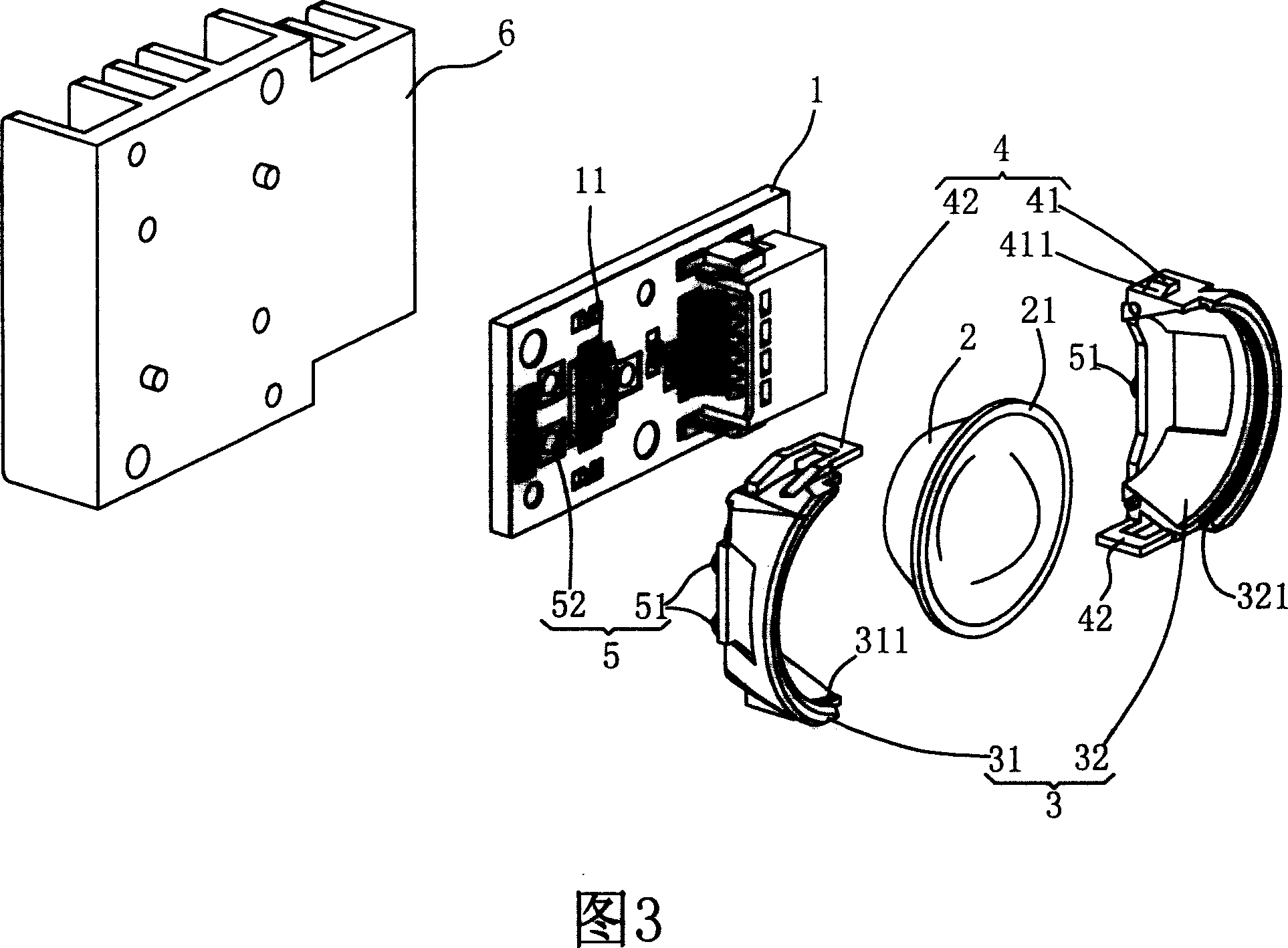

LED light-source collecting mould set and its holder

InactiveCN101075078AFast positioning and fixingMinimized contact surfaceProjectorsSolid-state devicesOptoelectronicsProjection system

A projection system comprises light source, light focusing unit for focusing light emitted from light source, display unit for generating image by utilizing light focused from focusing unit, projection lens unit for projecting and amplifying image generated by display unit, screen for displaying projected image, power level regulation unit for regulating power level provided to light source, power supply for providing power onto said regulation unit and power supply controller for confirming type of power supply and for controlling said regulation unit to provide proper power level.

Owner:PREMIER IMAGE TECH

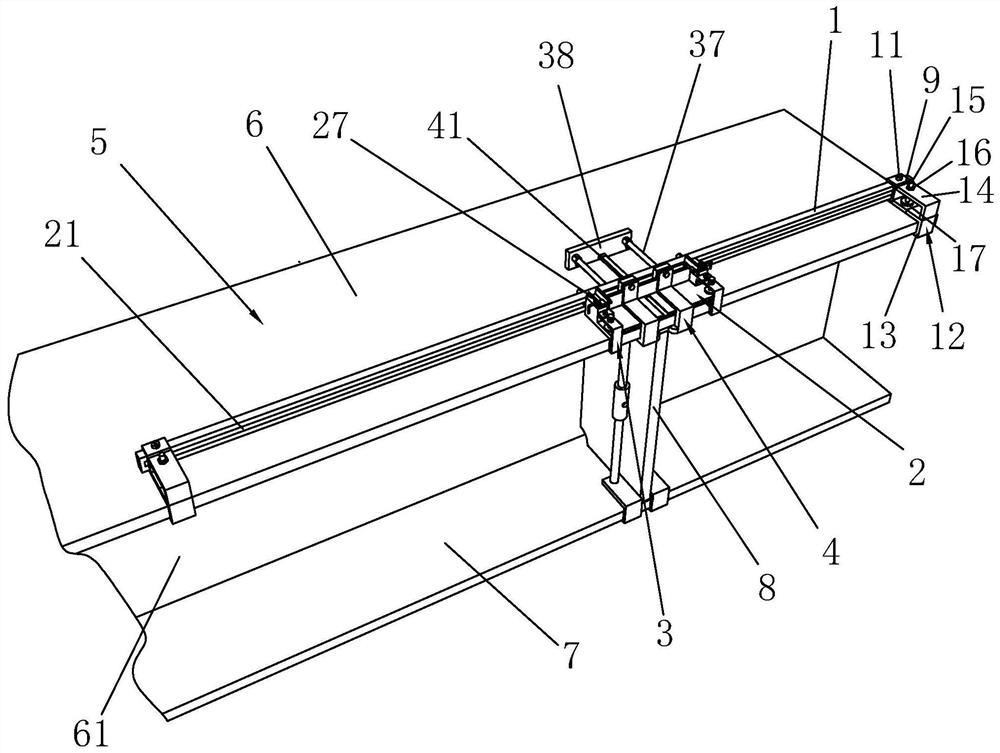

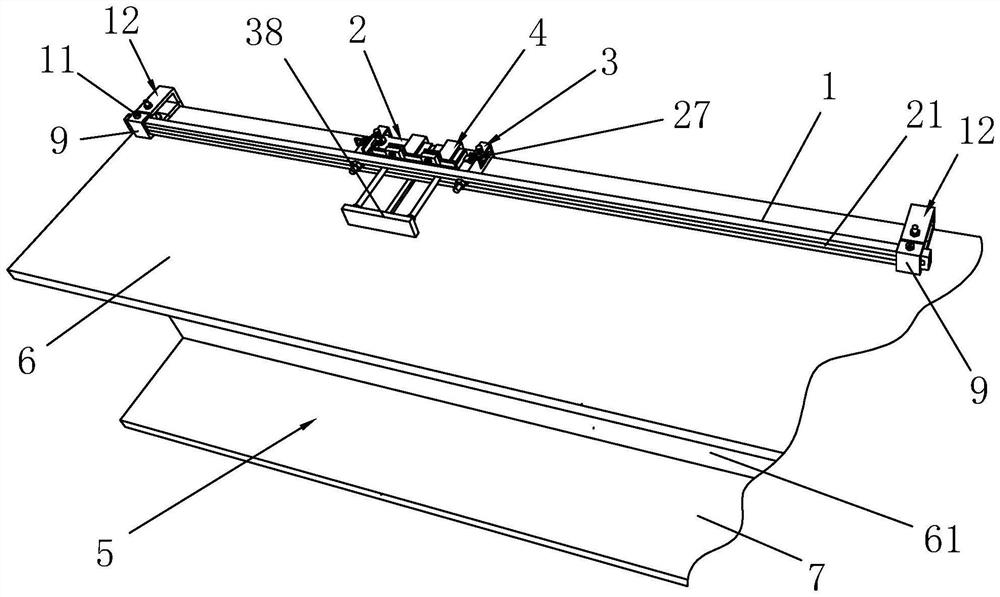

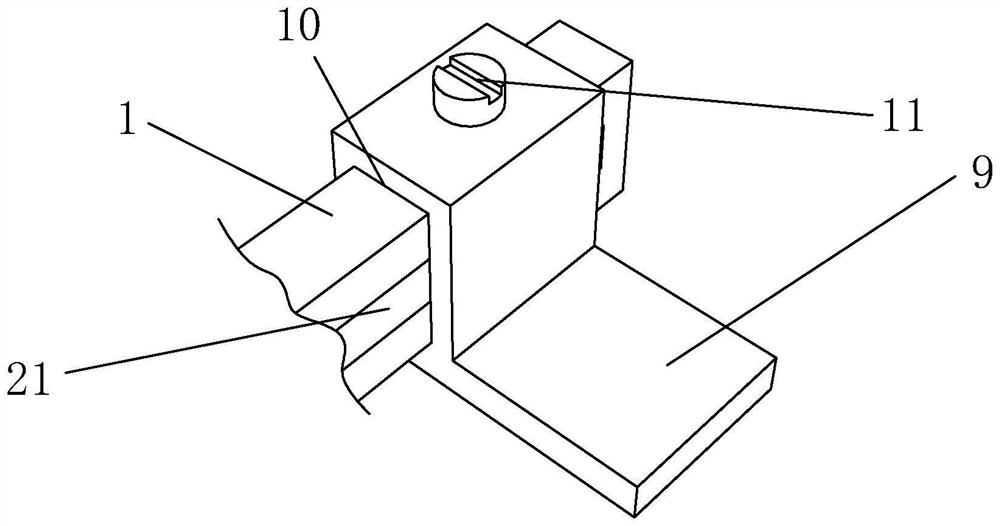

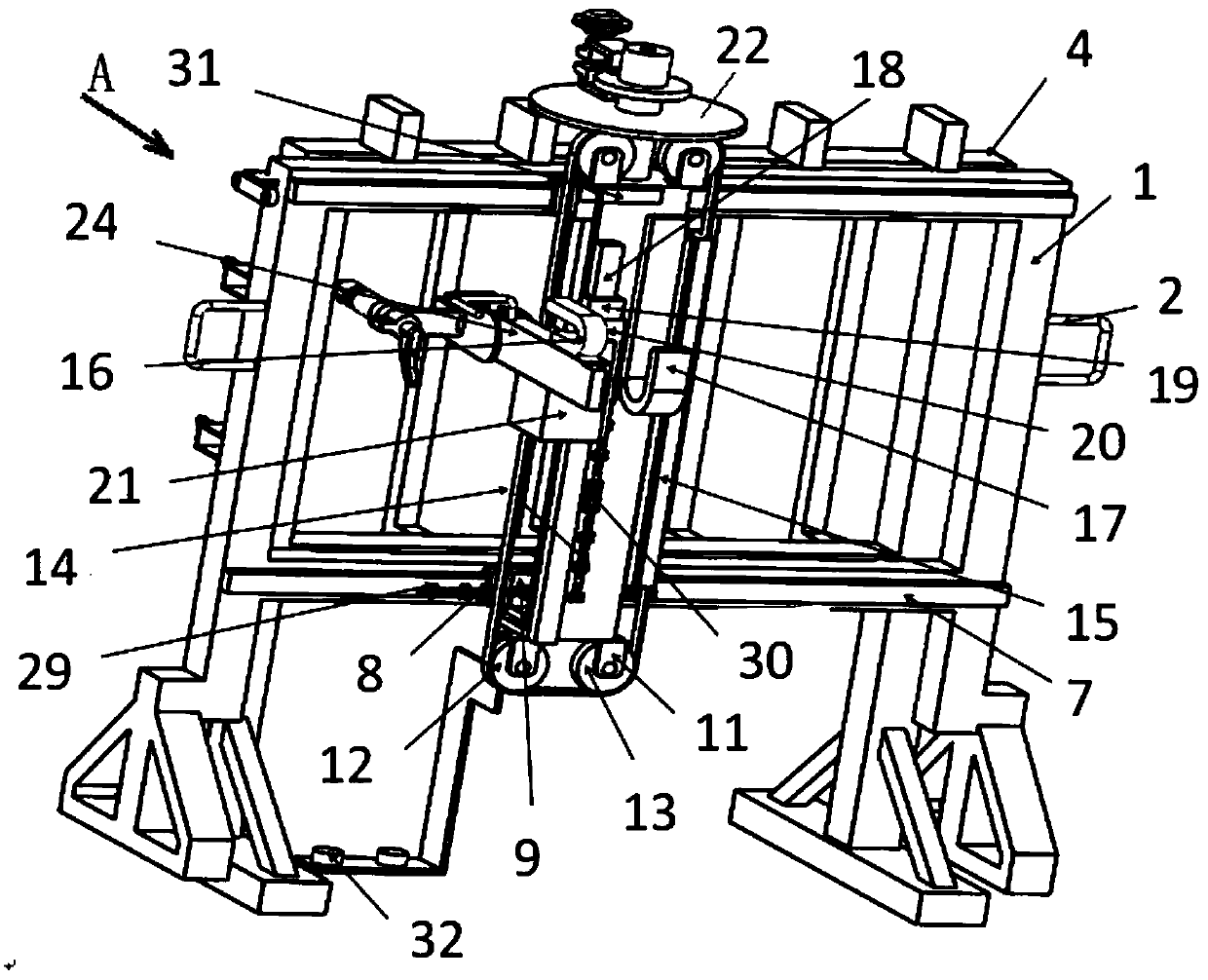

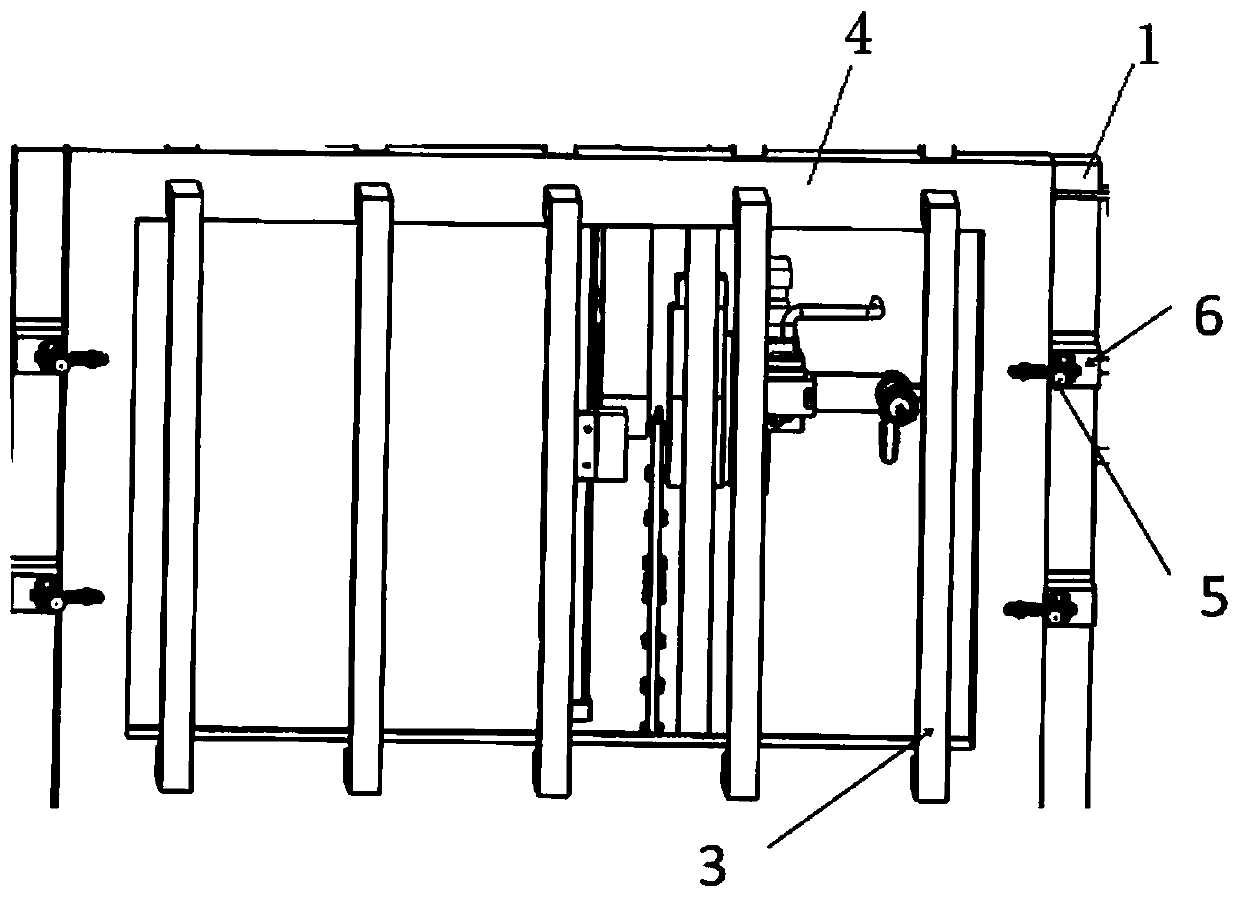

Accurate positioning method for stiffening plate of H-shaped steel component

PendingCN114227107AQuick fixEasy to adjustWelding/cutting auxillary devicesGirdersStructural engineeringIndustrial engineering

The invention discloses a precise positioning method for a stiffening plate of an H-shaped steel component. The precise positioning method comprises the following steps: 1) measuring, marking and carrying out region division; 2) installing a guide slide rail; (3) a movable limiting mechanism is installed, adjusted and positioned; 4) mounting an auxiliary fixing device; and (5) the connecting plates and the H-shaped steel beams are welded and fixed in sequence. The device is simple and reasonable in structural design, high in practicability, clear in principle and simple and convenient to adjust and operate, the H-shaped steel beam is segmented and divided in the length direction according to the length of the guide sliding rail and the actual length of the H-shaped steel beam, and step-by-step welding and positioning of the connecting plate are conducted with the divided segments as units; according to the auxiliary device for welding and fixing the connecting plates, the connecting plates at one division section are welded and installed firstly, after all the connecting plates in the division section are welded and installed, the whole auxiliary device is moved to the next division section, welding and positioning of the connecting plates at other division sections are conducted till welding and fixing of all the connecting plates are completed, the whole installation process is reasonable and scientific, and actual operation is convenient.

Owner:浙江中南绿建科技集团有限公司 +1

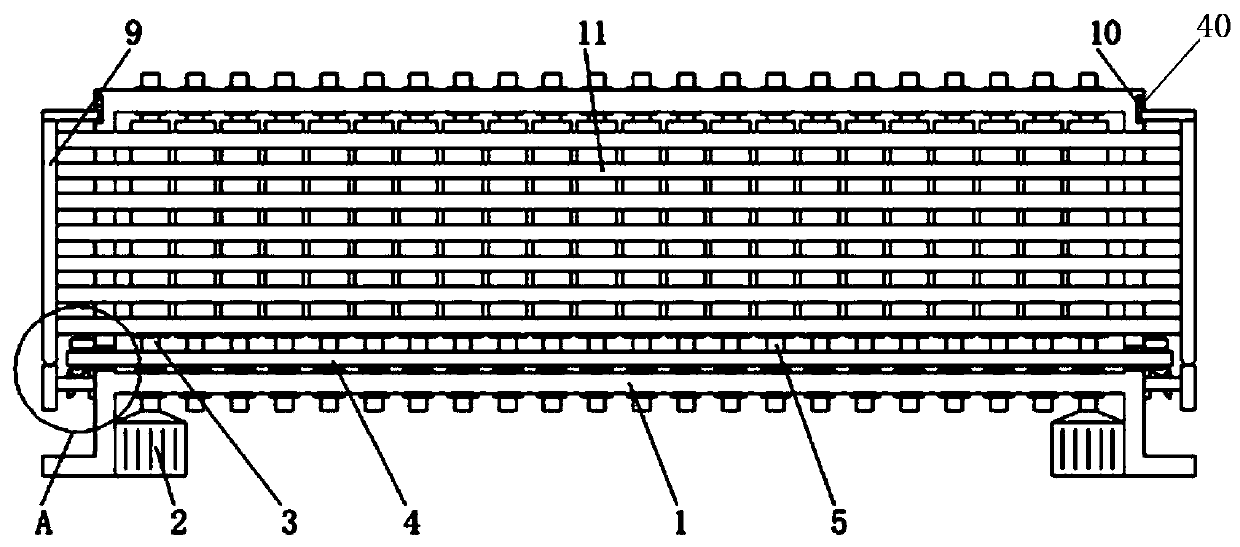

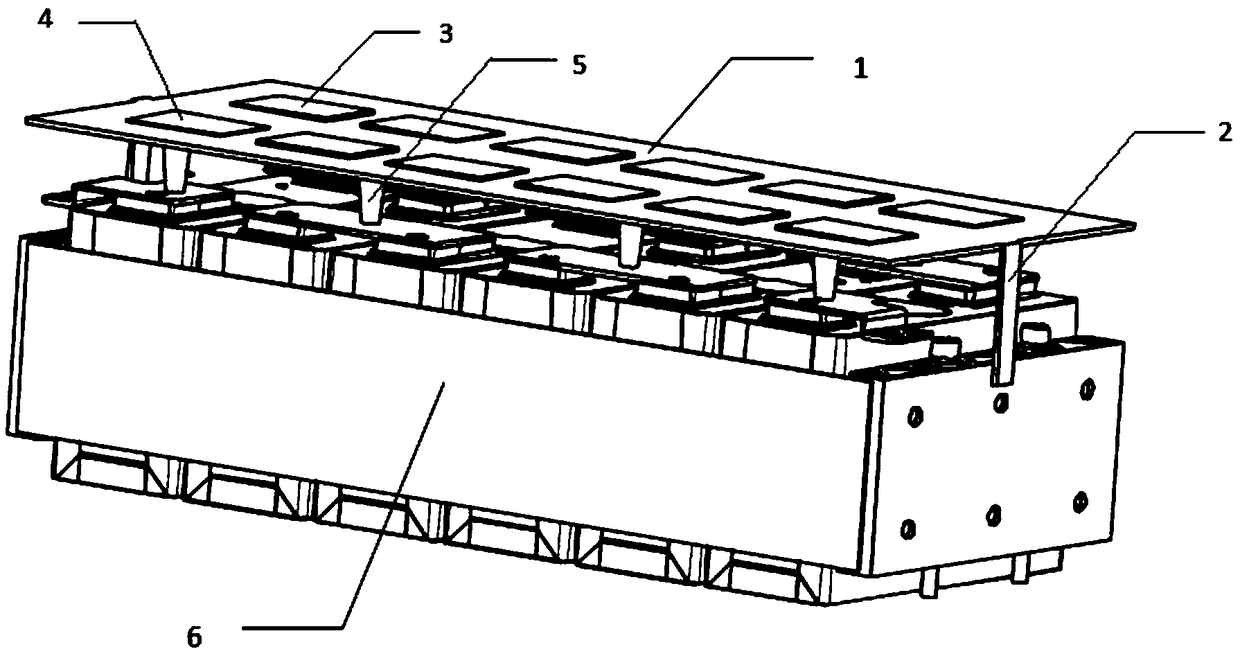

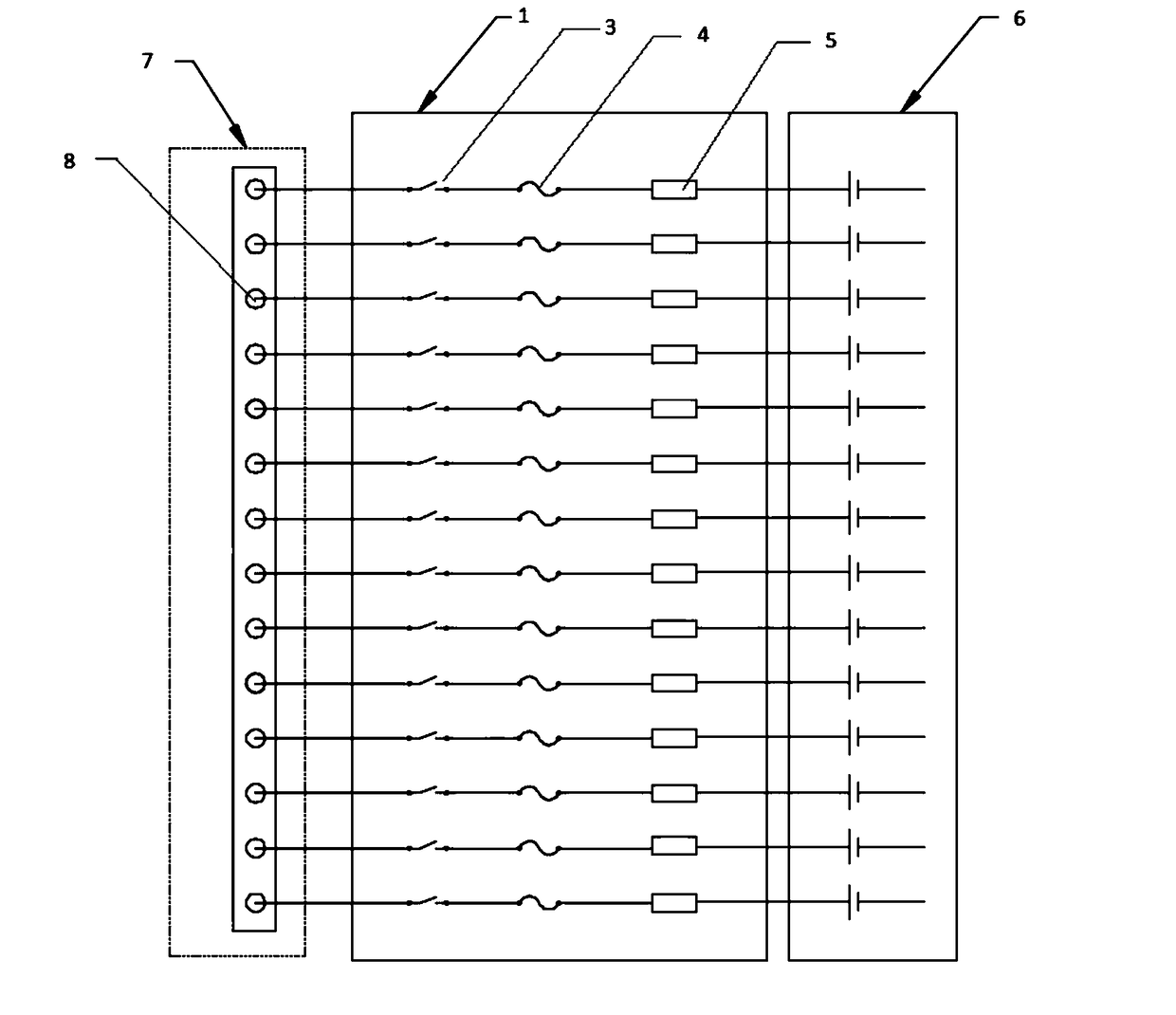

Battery standard box power supplying device

InactiveCN109274154ASolving Consistency IssuesTake advantage ofCharge equalisation circuitElectric powerElectrical resistance and conductancePower flow

the invention relates to a battery standard box power supplying device which comprises a positioning device and a plurality of independently arranged power supply loops, A plurality of power supply loops are independently arranged on the positioning device, the positioning device can be detachably clamped on the battery standard case, and a plurality of power supplement loops on the positioning device are arranged one by one corresponding to each single battery in the battery standard box and independently power supplement is carried out, The power supply loop can independently supply power toeach cell, and has no influence on each other. The power supply current and the power supply loop can be adjusted according to the actual demand. The large current can be used to supply power to thecells with large voltage difference, thereby shortening the power supply time and solving the consistency problem of the battery. A low-charge monome is supplied to that balance body dure the power supplement process, so that the energy is fully utilized, and the problem that the resistance energy dissipation cause heat and affects the SOC estimation accuracy of the battery system is avoided; Theinvention solves the problem of battery consistency and prolongs the service life of the battery system.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

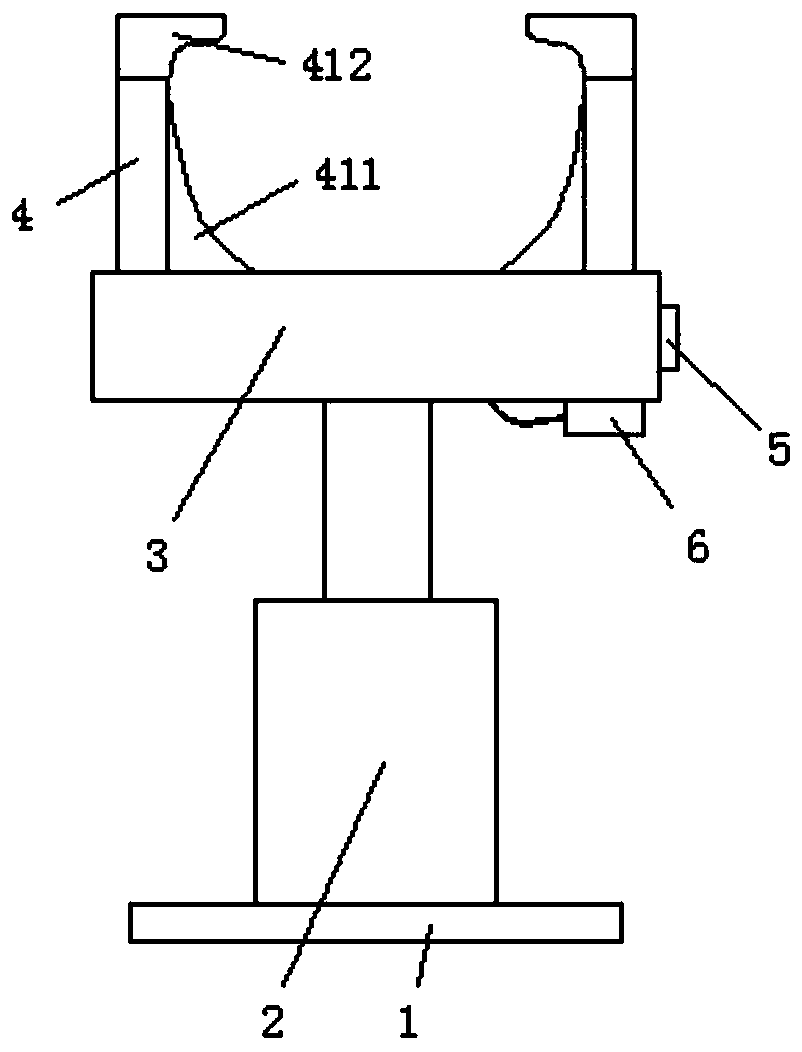

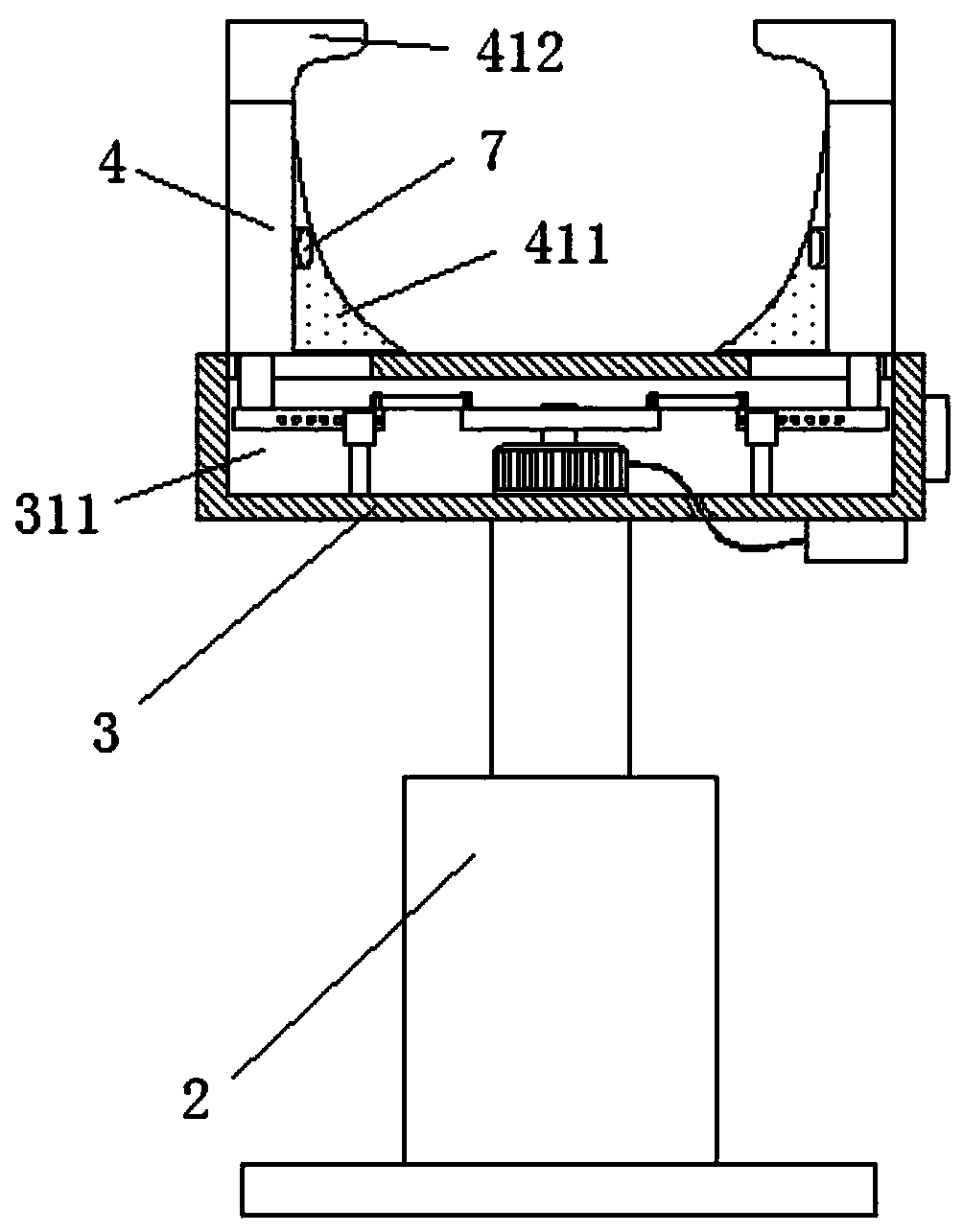

Positioning device for clinical nursing

InactiveCN111494025AHeight adjustable supportFast positioning and fixingApparatus for force/torque/work measurementInstruments for stereotaxic surgeryClinical nursingMedical practitioner

The invention discloses a positioning device for clinical nursing. The positioning device comprises a fixed bottom plate, and an electric telescopic device is fixedly mounted at the top of the fixed bottom plate; leg supporting blocks are fixedly mounted at the output ends of the electric telescopic devices; leg positioning frames are movably installed on the two sides of the tops of the leg supporting blocks, the two leg positioning frames are symmetrically arranged, buffer bodies are fixedly arranged on the lower portions of the sides, close to each other, of the two leg positioning frames,rubber structural bodies are fixedly connected to the tops of the sides, close to each other, of the two leg positioning frames, and the inner sides of the rubber structural bodies are in a hook shape. The positioning device for clinical nursing is simple in structure and convenient and fast to operate, capable of accurately and effectively positioning and fixing the legs, and capable of preventing the legs from being injured in the positioning and fixing process; positioning and fixing of the legs are stable, so that follow-up nursing operation can be conducted smoothly; and positioning in doctor nursing becomes convenient.

Owner:秦美乐

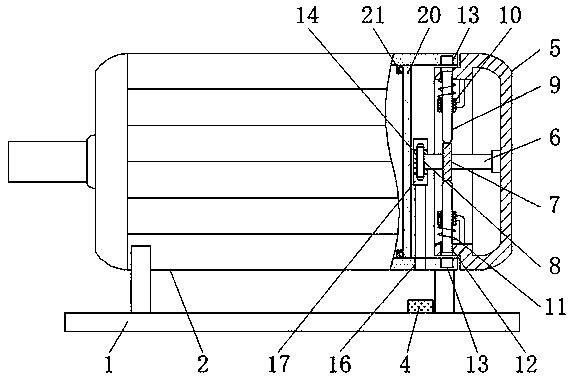

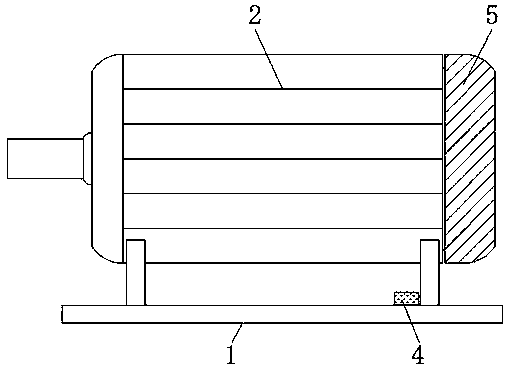

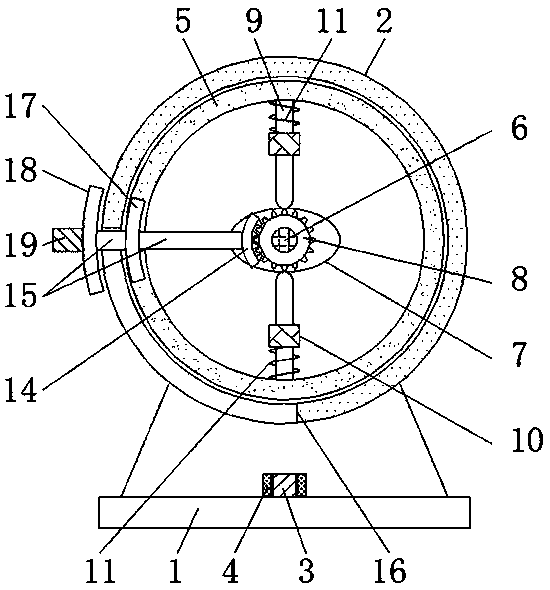

Asynchronous motor shell with alignment self-locking structure

ActiveCN110429741AEasy to disassembleEasy to take outSupports/enclosures/casingsSelf lockingEngineering

Owner:肇庆锐滔五金制品有限公司

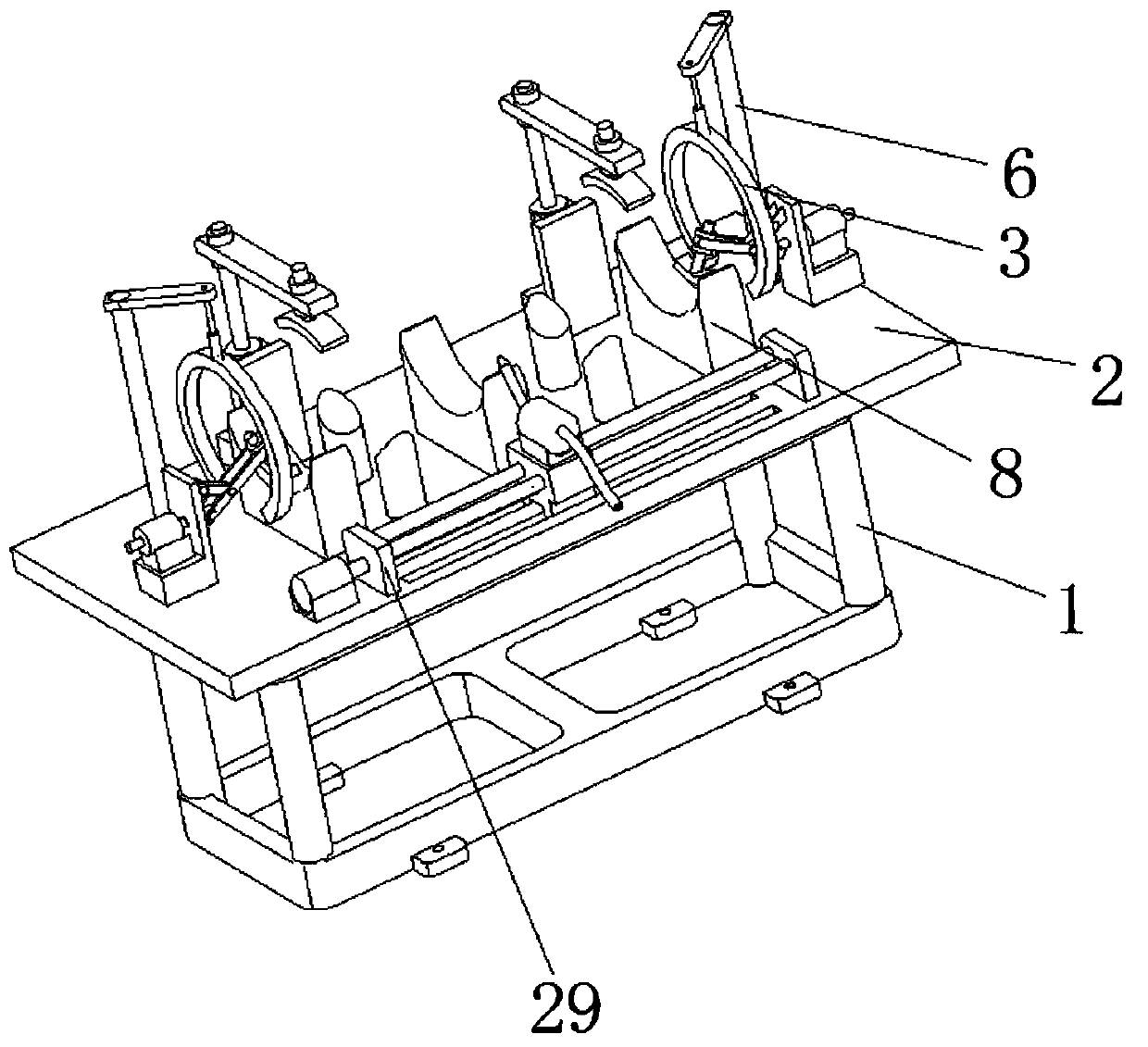

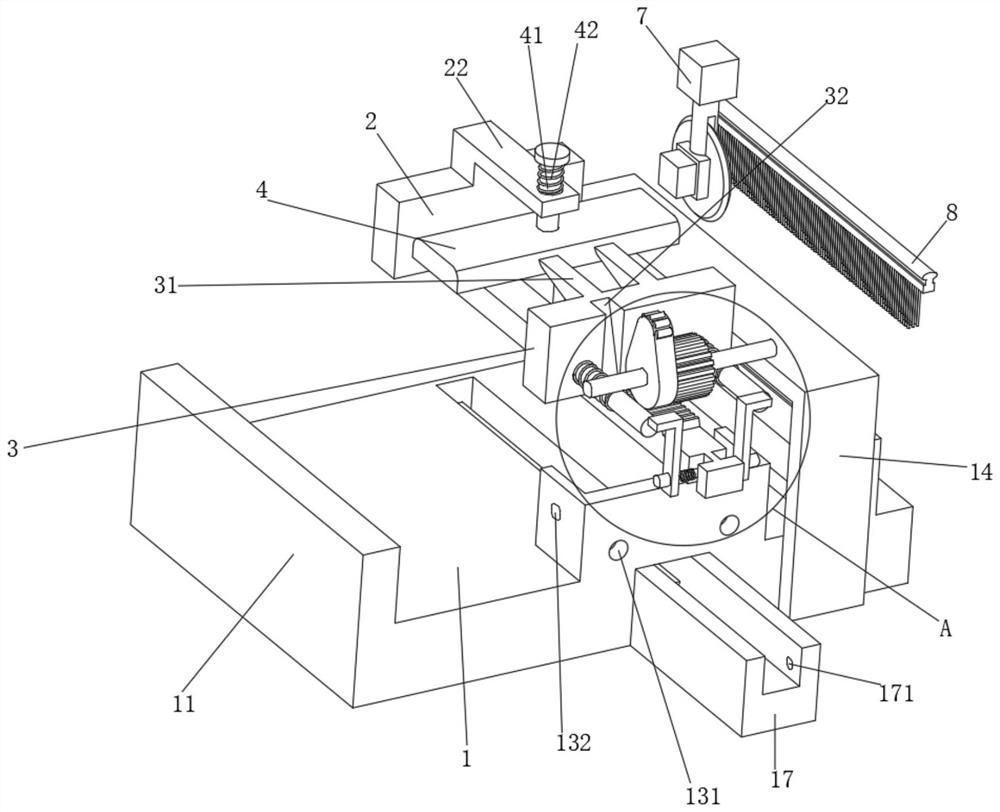

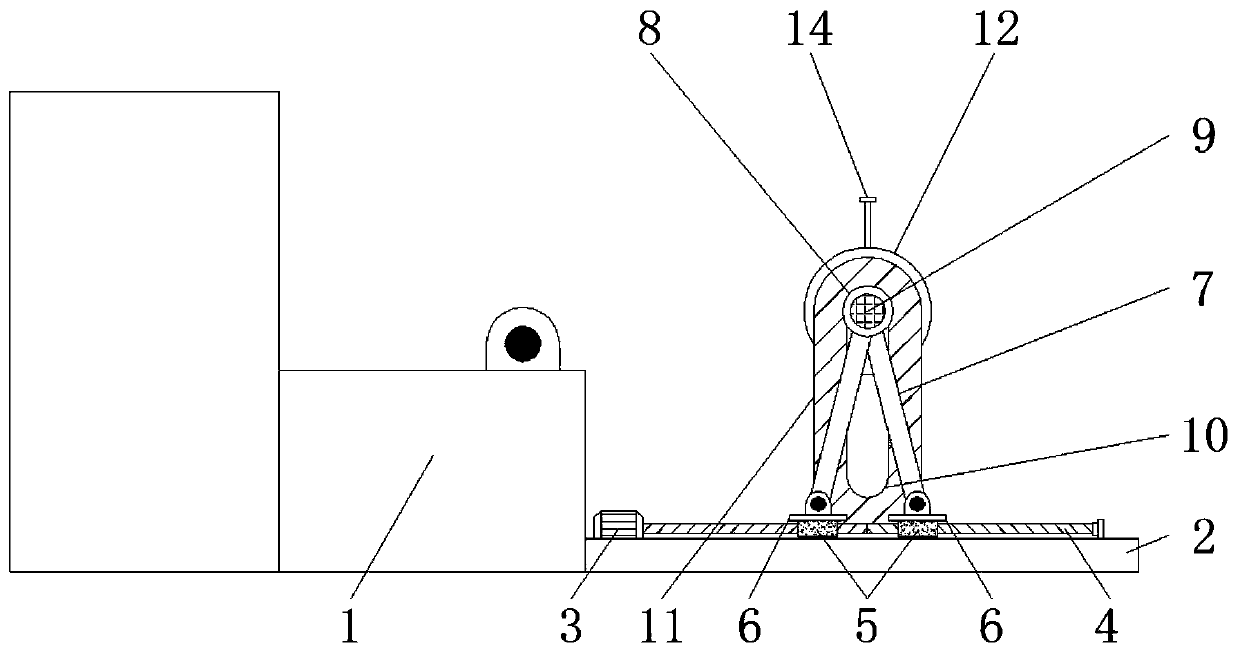

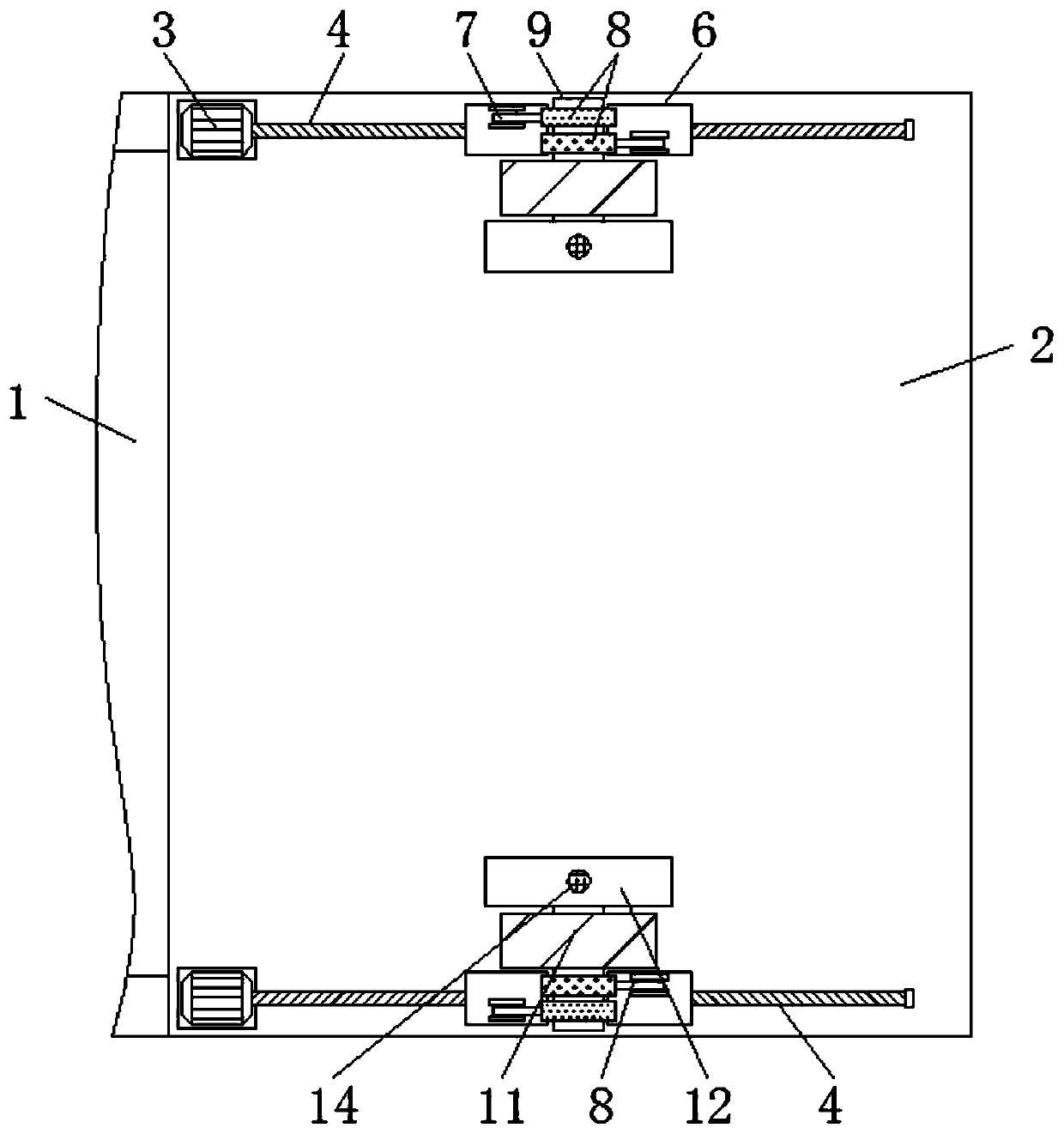

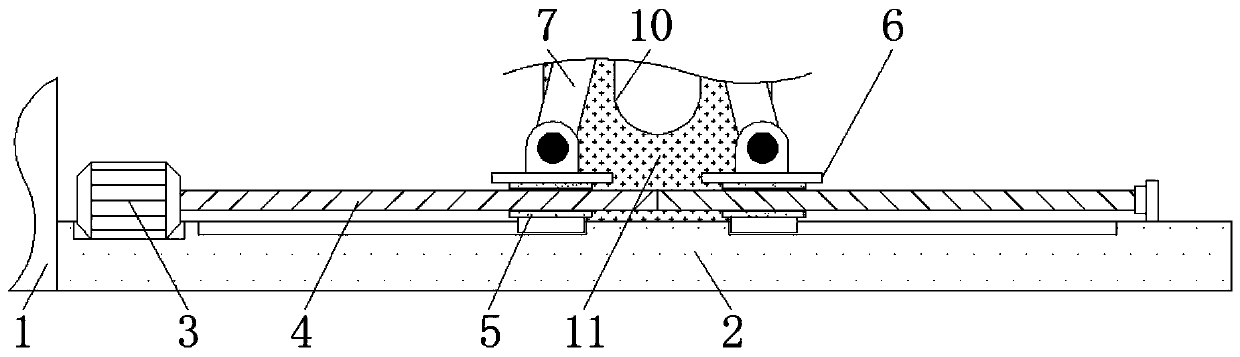

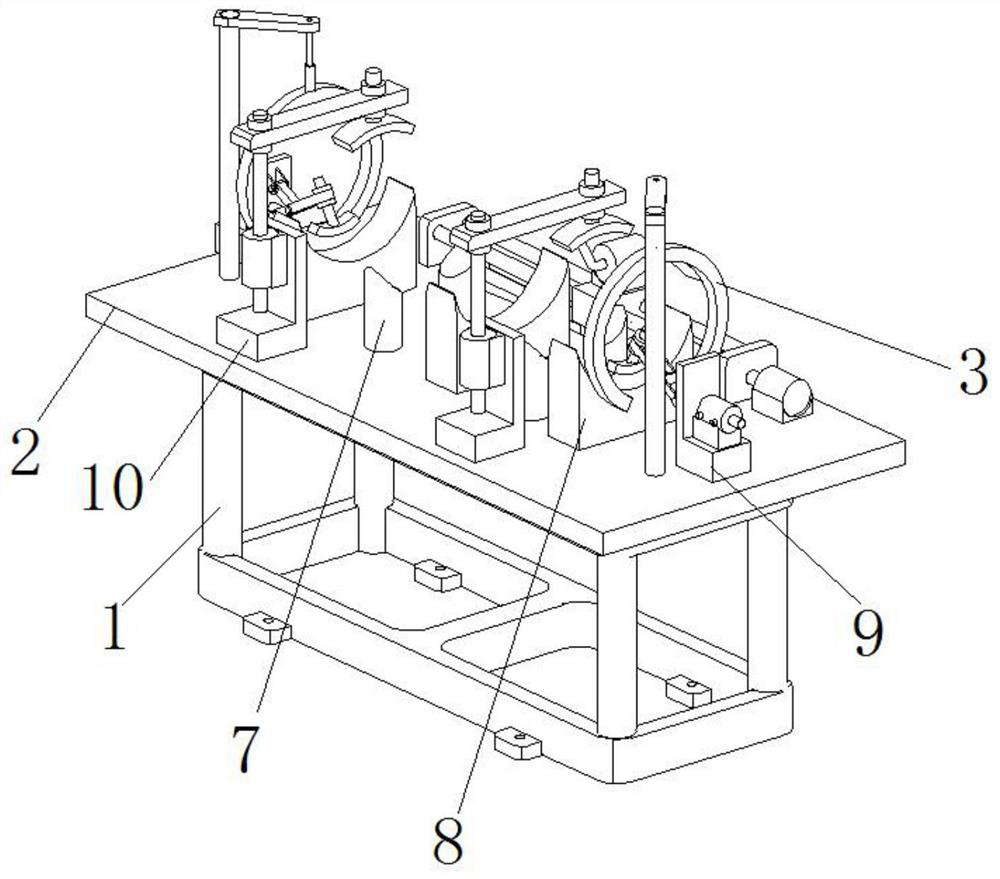

Space clamp clamping mechanism

InactiveCN113894575AFast positioning and fixingEasy to processPositioning apparatusMaintainance and safety accessoriesElectric machineryMachining

The invention provides a space clamp clamping mechanism. The mechanism comprises a working plate, a moving mechanism is arranged at the top of the working plate, a top limiting mechanism is arranged at the top of the moving mechanism, a bottom limiting mechanism is arranged at the end, away from the top limiting mechanism, of the moving mechanism, a clamping mechanism is arranged between the working plate and the moving mechanism, and a rotating mechanism is arranged at one end of the top of the clamping mechanism. The mechanism has the advantages that through movement of the top limiting mechanism and the bottom limiting mechanism, the two ends of a part can be conveniently and rapidly positioned and fixed. By using the clamping mechanism and the rotating mechanism, the positions and angles of the part can be adjusted and changed, and the mechanism can be conveniently machined. The pressure on the part is reduced through a first spring, vibration during machining is reduced, and damage caused by too large stress on the part is prevented through the trapezoidal extrusion end. A second spring extrudes an extension rod to move, so that the extension rod is conveniently inserted into a fixed disc, and the output end of a second stepping motor is conveniently fixed and prevented from rotating.

Owner:上海槎南工贸发展有限公司

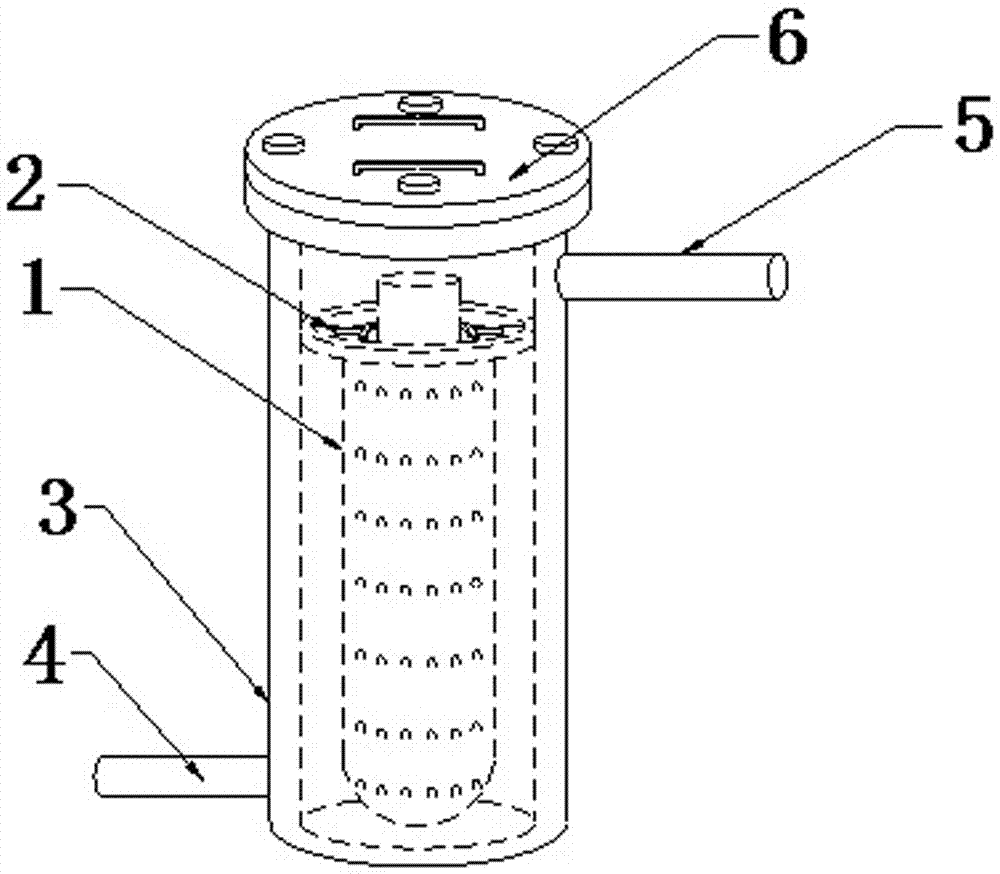

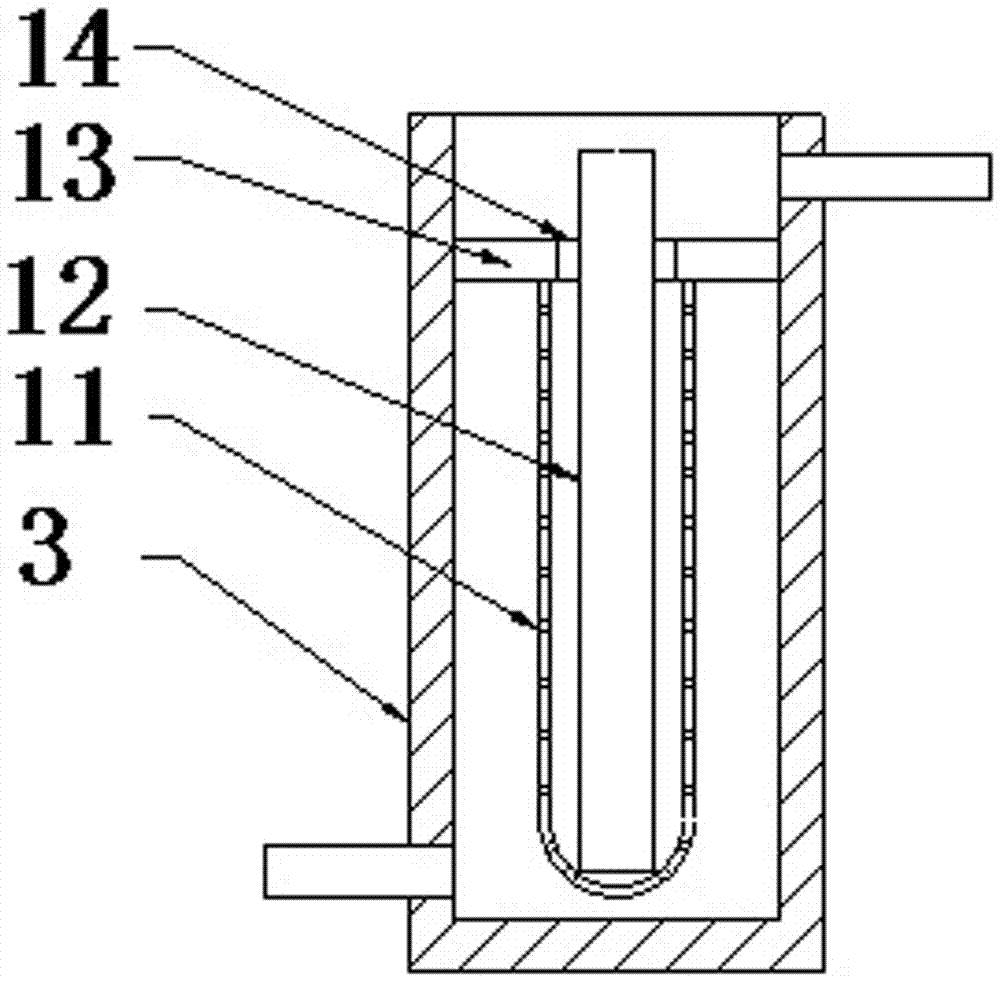

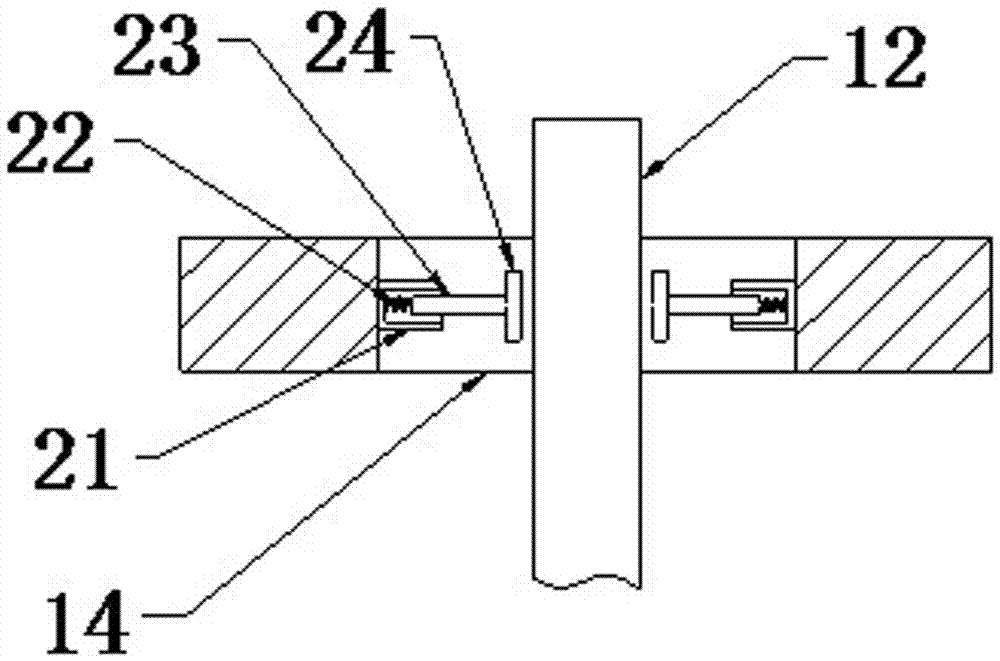

Iron removal device for impregnating agent and application method for iron removal device

PendingCN107321497AImprove qualityRealize the filtering functionMagnetic separationIron removalStructural engineering

The invention provides an iron removal device for an impregnating agent. The iron removal device comprises a filter screen, a magnet rod, a bearing disc, a through hole, guide sleeves, return springs, guide rods and clamping plates; the filter screen is arranged in the middle of the lower end surface of the bearing disc; the magnet bar penetrates through the through hole and is assembled in the filter screen; the bearing disc is arranged in a cylinder body; and the through hole is formed in the middle position of the bearing disc. According to the design of the iron removal device, the functions of rapidly filtering and adsorbing impurities and iron impurities in the impregnating agent can be achieved, the guide sleeves are fixed to the left part of the annular side surface in the through hole, the return springs are arranged in the guide sleeves, the guide rods are assembled in the guide sleeves, the clamping plates are fixed to the right end surfaces of the guide rods, and therefore the magnet rod can be quickly positioned and fixed, the situation that the magnet bar moves can be avoided, and the adsorption effect of the magnet rod can be improved. The invention further provides an application method for the iron removal device for the impregnating agent. The device has the advantages of being reasonable in structure, good in filtering effect, good in stability, high in practicability and high in reliability.

Owner:重庆天泽新材料有限公司

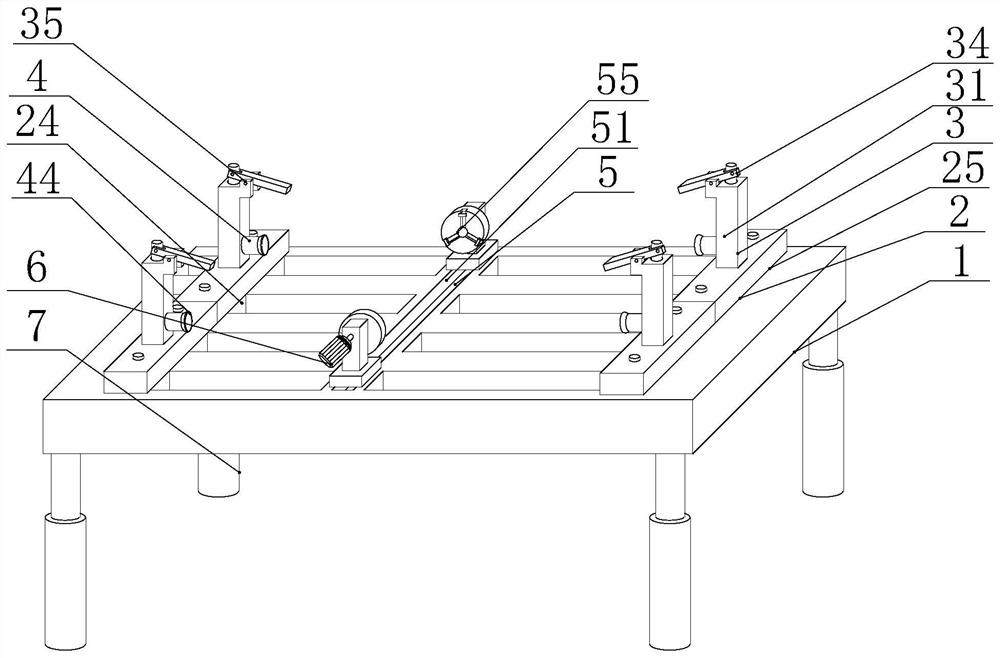

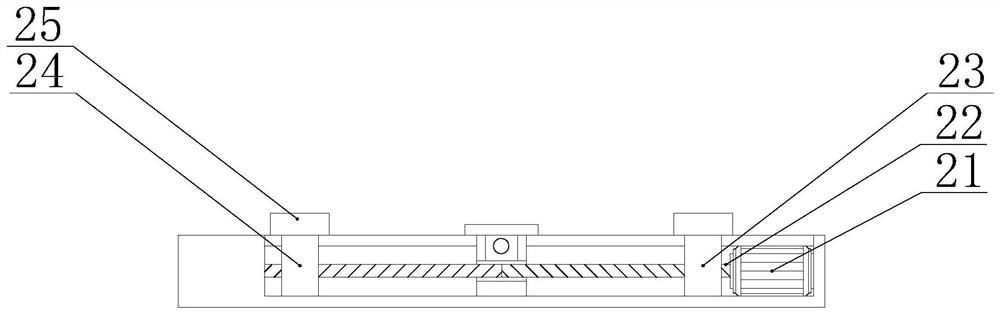

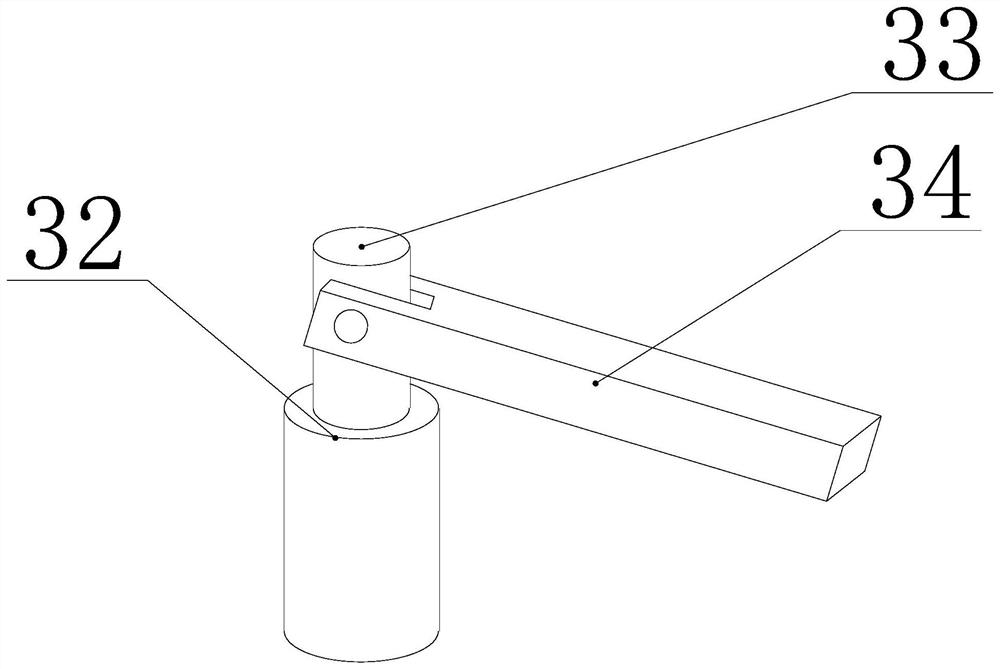

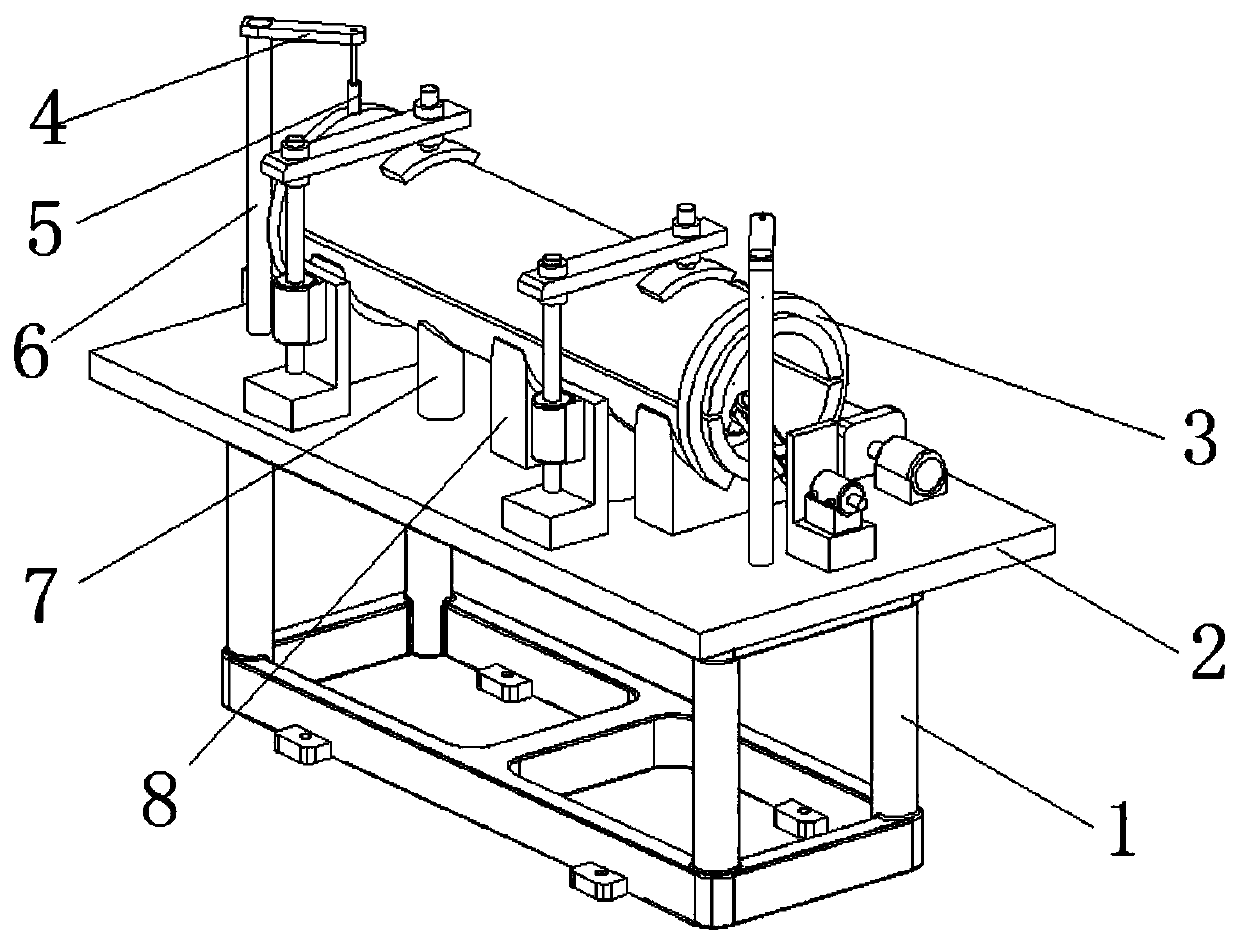

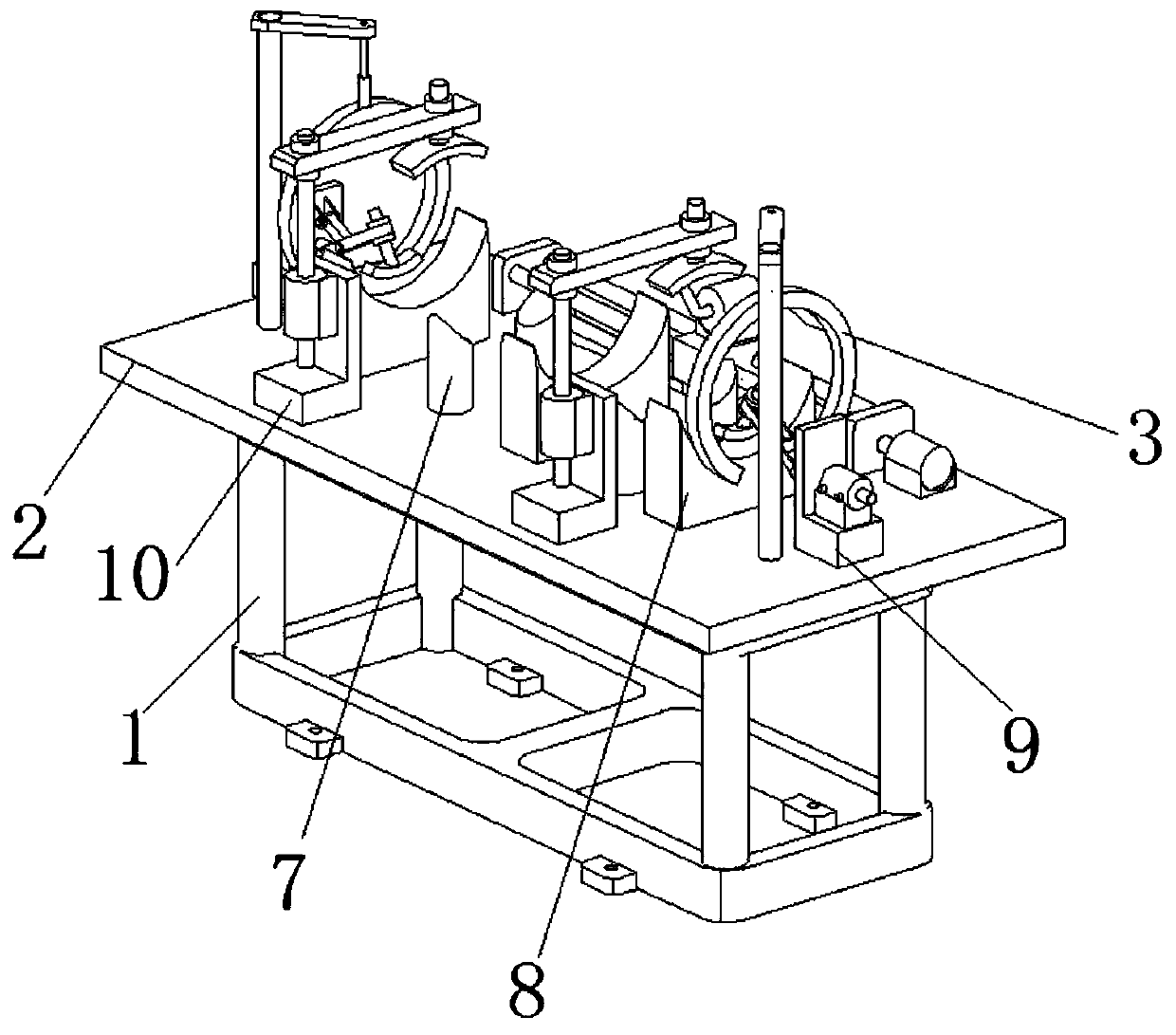

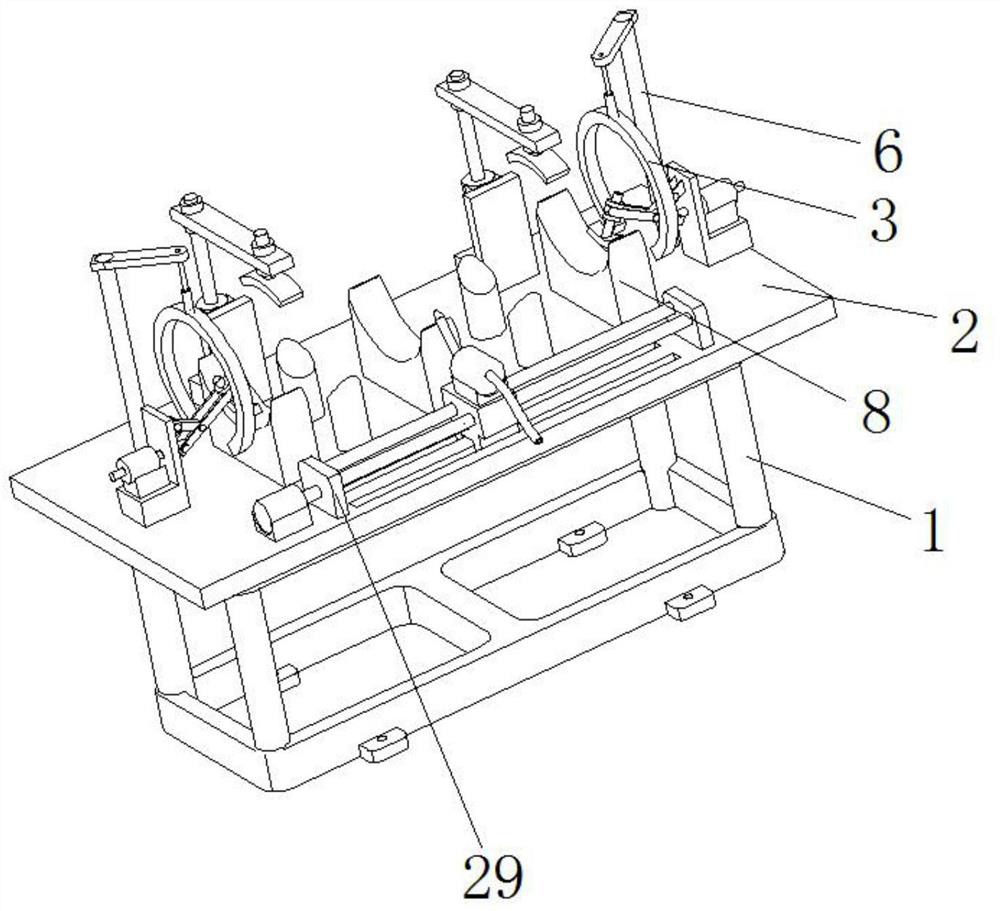

Dual-way welding clamp for laser welding

ActiveCN111136394ASolve process requirementsAddress welding quality requirementsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser soldering

The invention discloses a dual-way welding clamp for laser welding, and relates to the field of welding tool clamps. The problems that positioning, clamping and assembling effects of pipeline type part laser welding of a current dual-way welding clamp are poor, and a welding part product cannot meet process and welding quality needs can be solved. According to the following scheme, the clamp comprises a frame and a mounting plate, positioning columns and supporting blocks are fixedly mounted on the upper surface of the mounting plate, and are evenly distributed, welding part bodies are placedon the positioning columns and the supporting blocks, first mounting bases and second mounting bases are fixedly mounted on the upper surface of the mounting plate in an evenly-distributed manner, first air cylinders are fixedly mounted on one sides of the two sets of first mounting bases in the horizontal direction, first ejector rods are slidingly mounted in the first air cylinders, and penetrate through the outer walls of one sides of the first mounting bases, and the clamp is novel in structure, easy to operate, rapid to use and suitable for being popularized.

Owner:JILIN UNIV

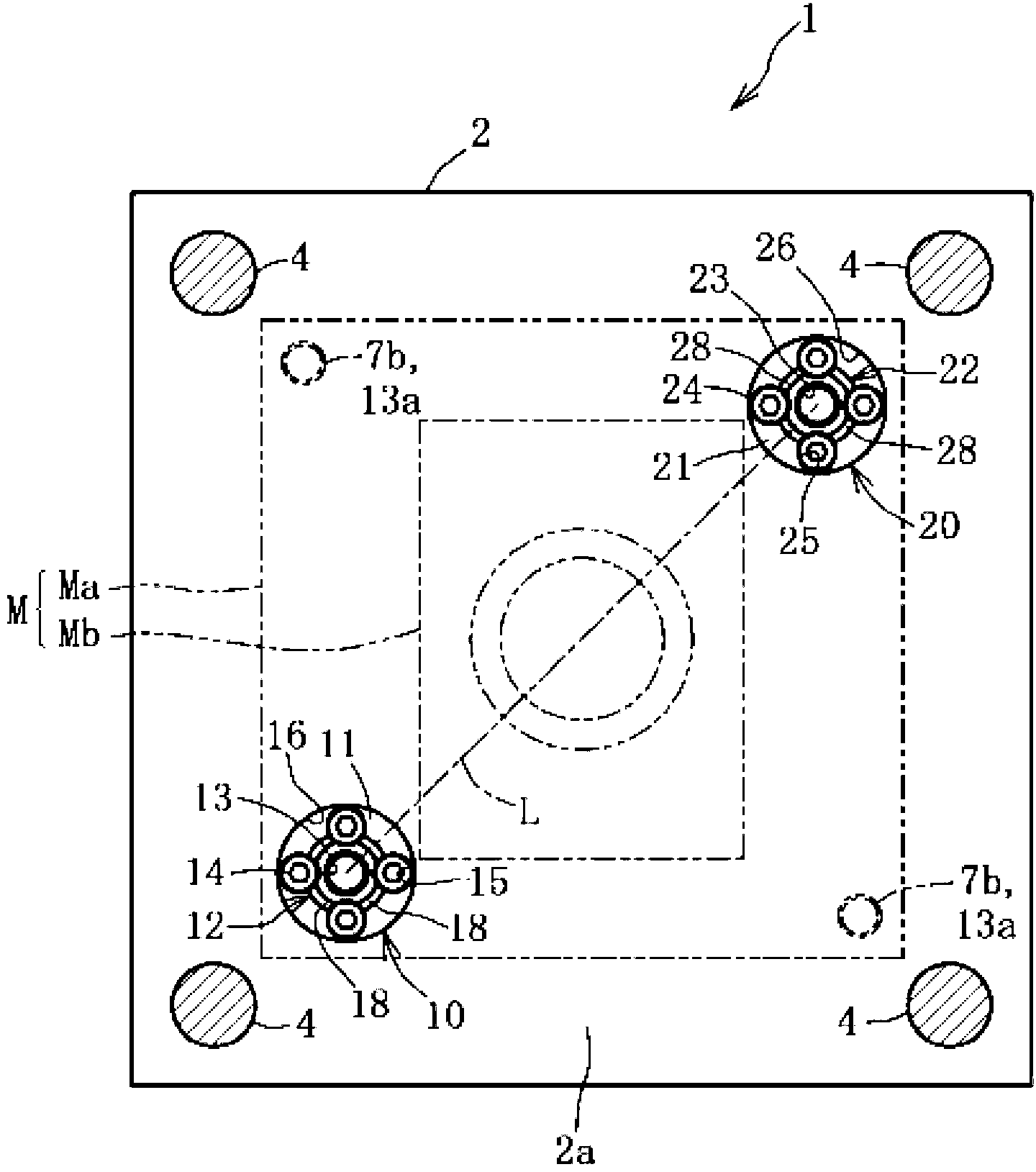

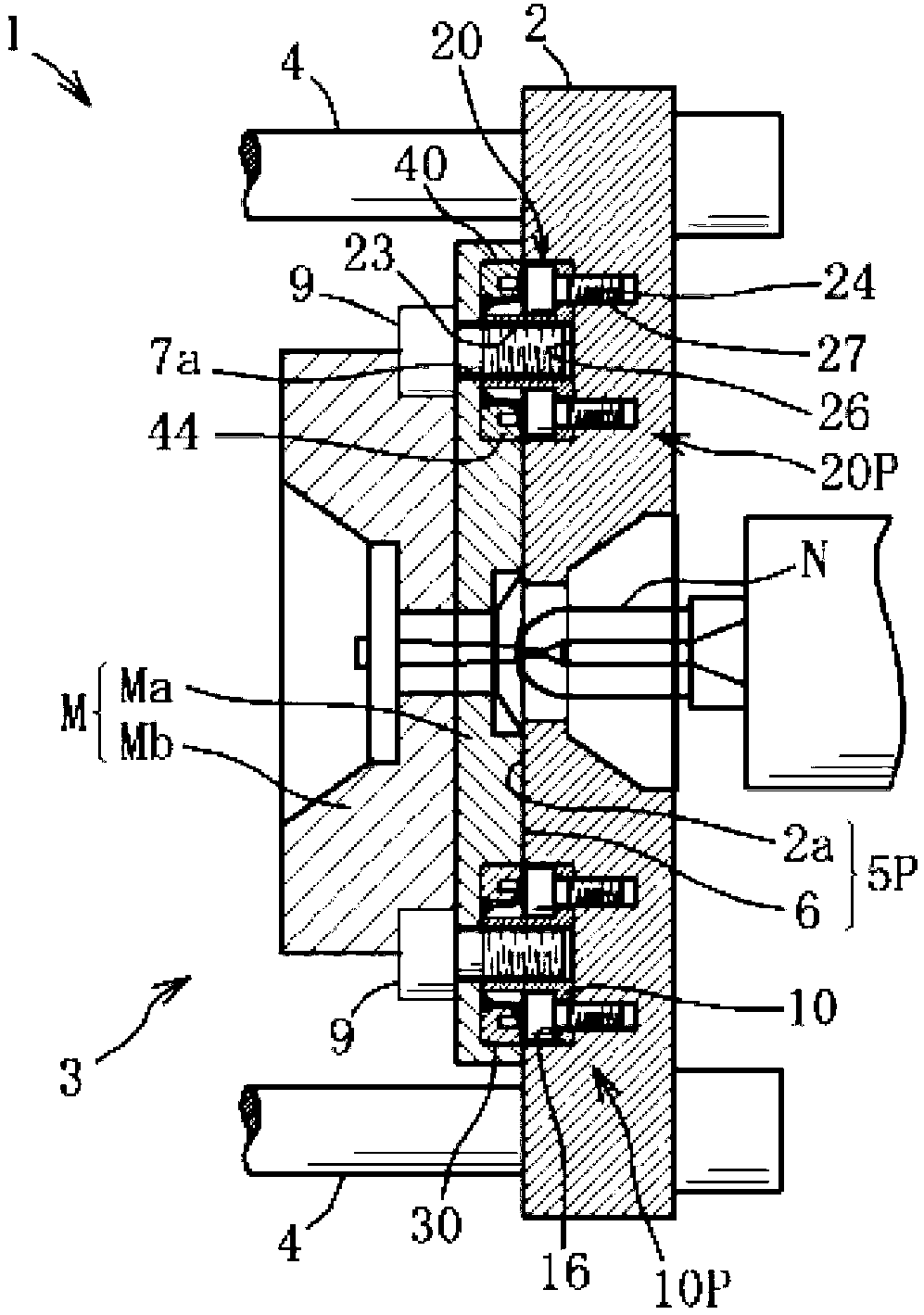

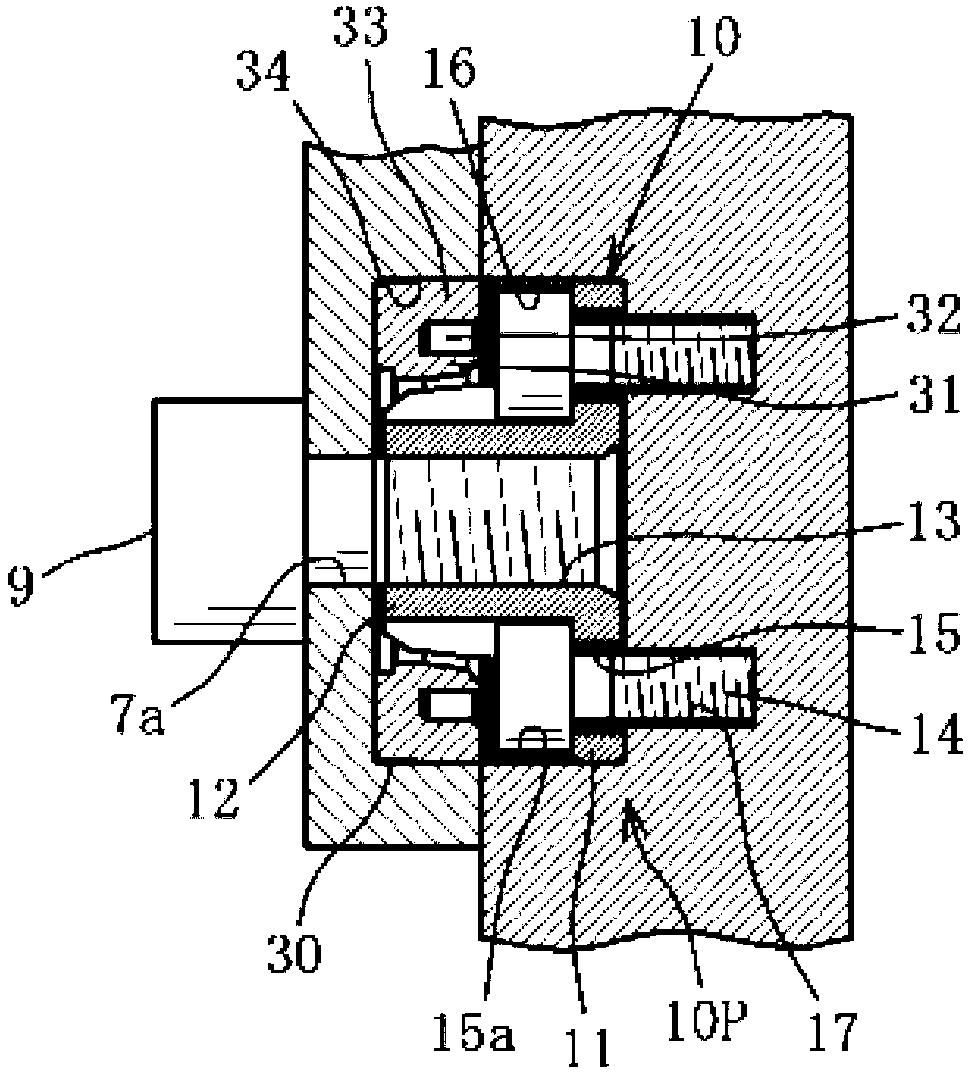

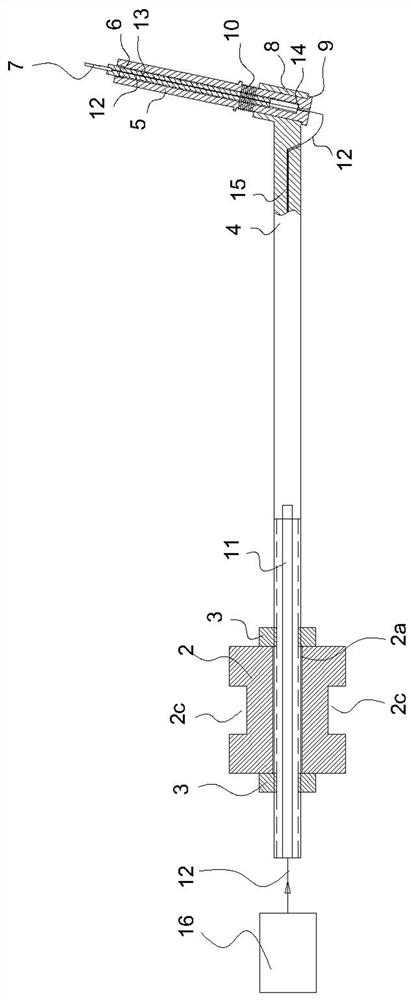

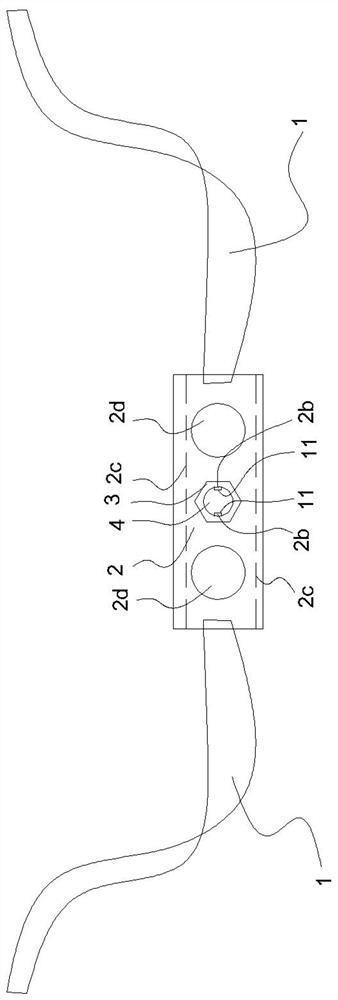

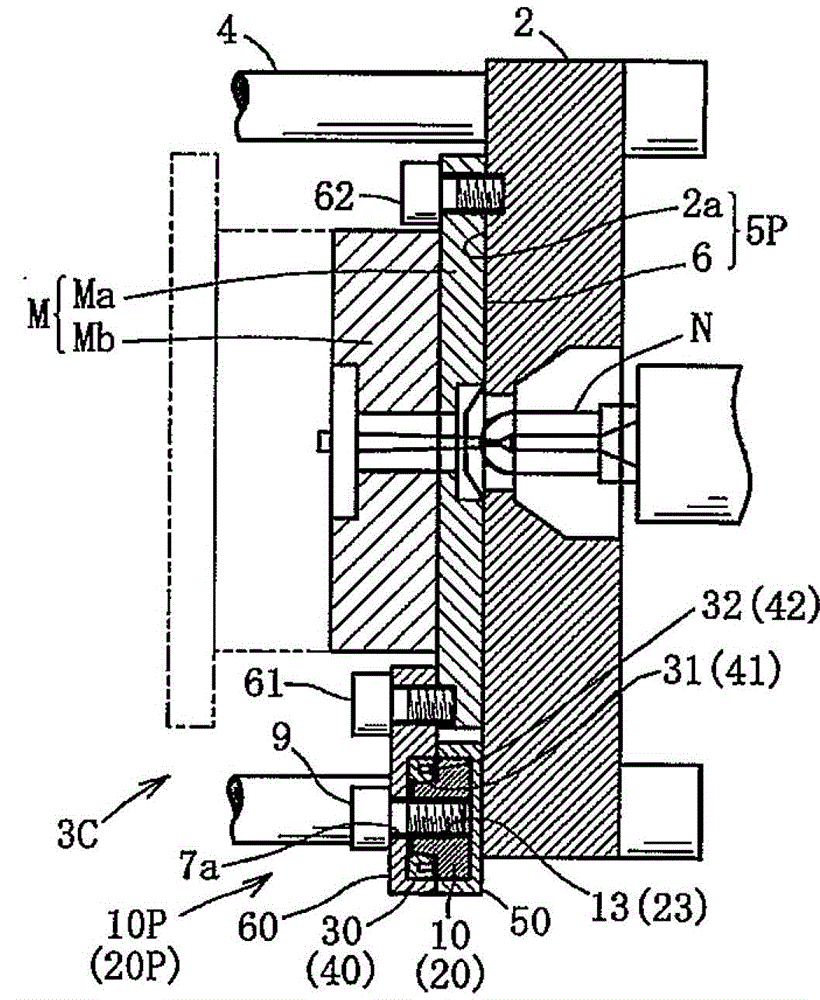

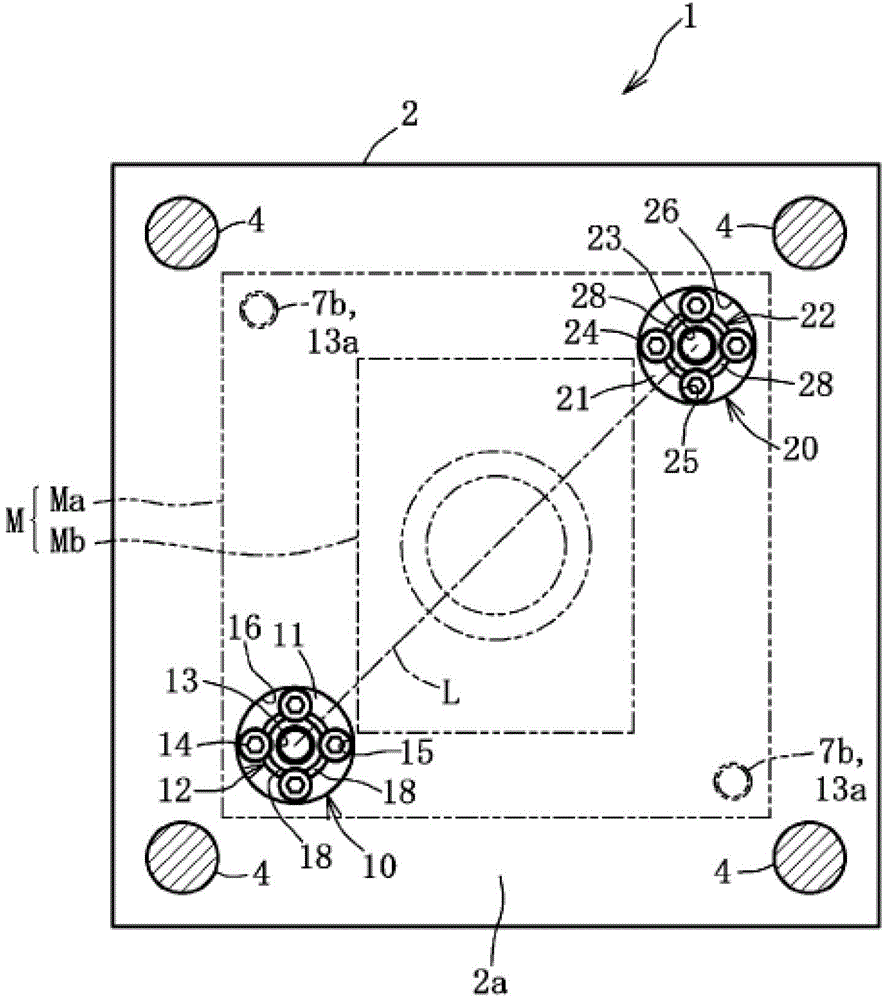

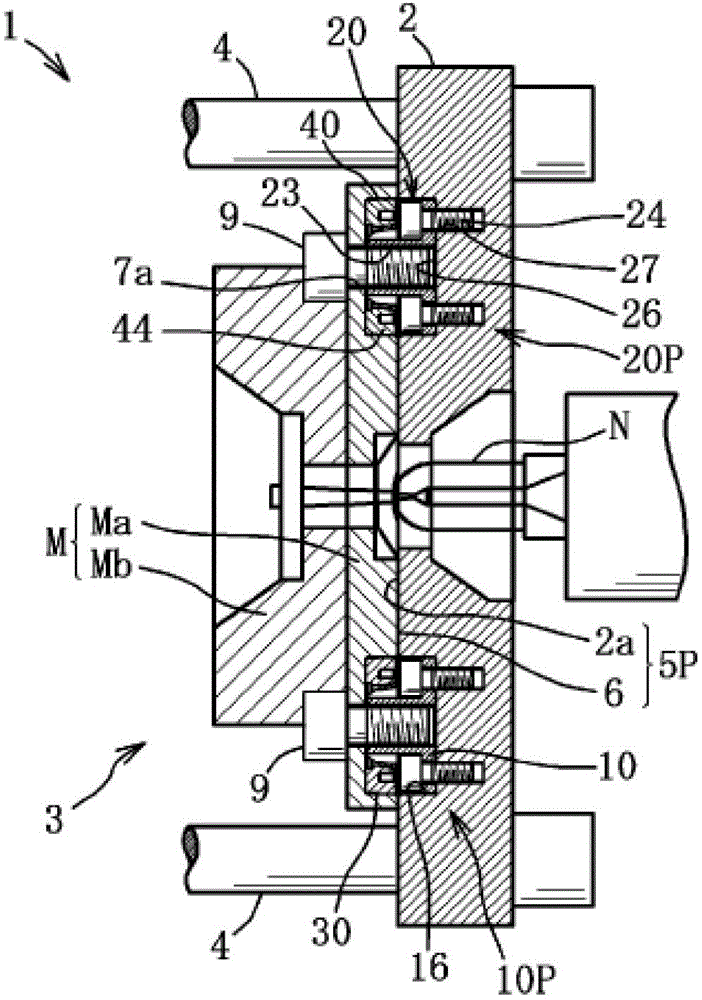

Metal mold positioning and fixing device

Disclosed is a metal mold positioning and fixing device which positions a metal mold (M) on a board surface (2a) of a board member (2), in the directions parallel and orthogonal to the board surface, and fixes the mold thereto. In the device: the metal mold and the board member are provided with a first positioning mechanism which positions the metal mold in the direction parallel to the board surface, a second positioning mechanism for positioning, which is arranged in a position separated from the first positioning mechanism, and an orthogonal direction positioning mechanism which positions the metal mold in the direction orthogonal to the board surface,each of the positioning mechanisms are provided with tapered engaging protrusions (12, 22) on the board member side, and annular engagement sections (31, 41) which are provided on the metal mold side and which can engage with the tapered engaging protrusions. The device is provided with a plurality of bolt holes (13, 23) formed on the board member side, a plurality of bolt insertion holes (7a) formed on the metal mold side, and a plurality of bolts for clamping which can be inserted into the respective insertion holes and screwed into the respective bolt holes,and the device is formed such that annular engagement sections (31, 41) are each elastically deformed toward the outer diameter expansion side due to the fastening of the bolts for clamping, and thus are adhered to the tapered engaging protrusions (12, 22).

Owner:PASCAL ENG

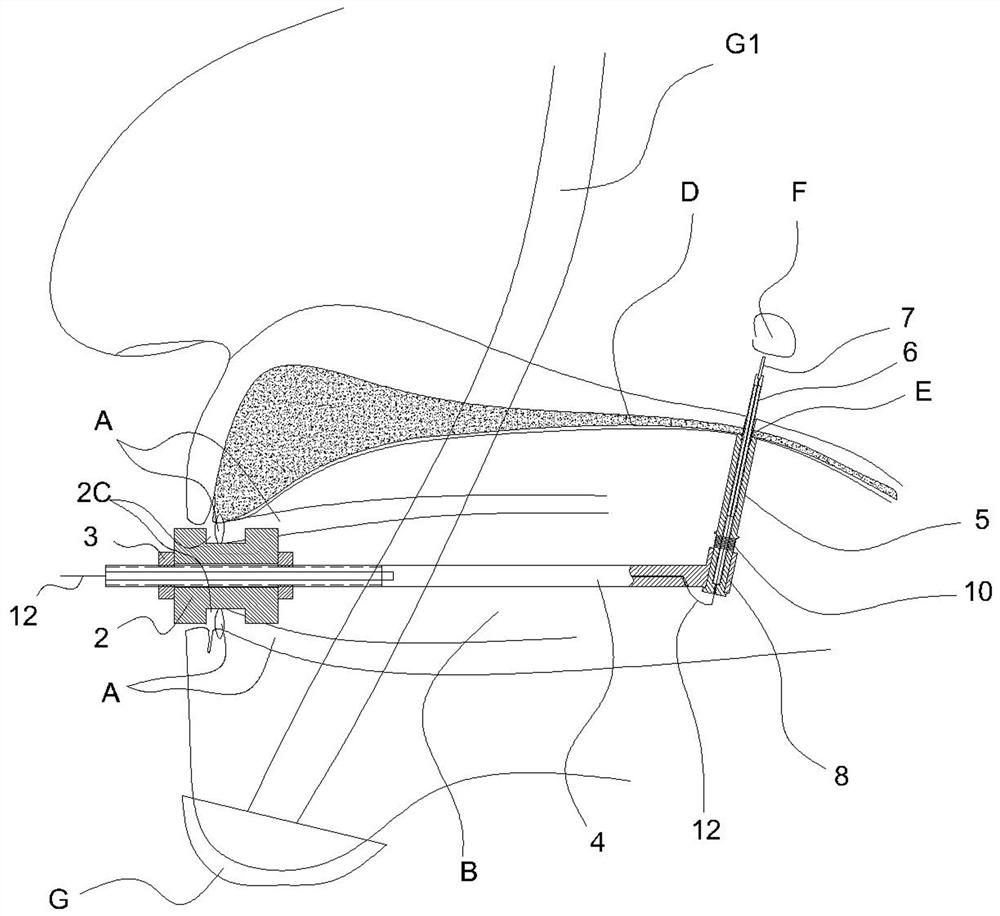

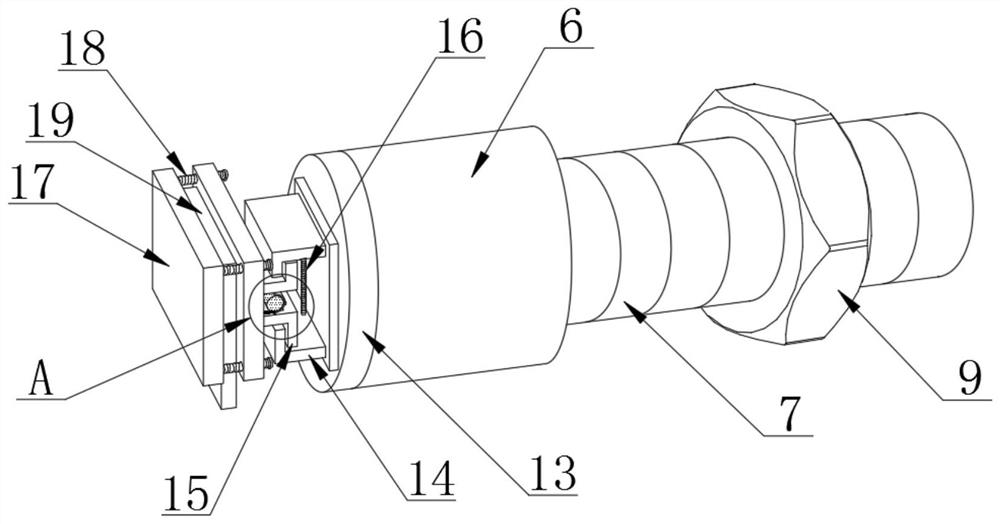

Nerve stimulator

PendingCN111643813AFast positioning and fixingSkin piercing electrodesExternal electrodesElectro stimulationBiomedical engineering

The invention discloses a nerve stimulator. The nerve stimulator is characterized by comprising a tooth socket fixing seat with a bandage, a rod connected to the tooth socket fixing seat in a penetrating mode and fixed to the tooth socket fixing seat through a fixing piece, and an electrode component arranged at one end of the rod, wherein the electrode component comprises a sleeve with an internal thread connected to one end of the rod, a screw with one end threaded into the sleeve, and an electrode disposed at the other end of the screw. Compared with the prior art, the nerve stimulator hasthe advantages that the electrode can be quickly positioned and fixed at the disc ala ganglion, so that the disc ala ganglion treatment can be electrically stimulated at the first time.

Owner:曹冰倩 +1

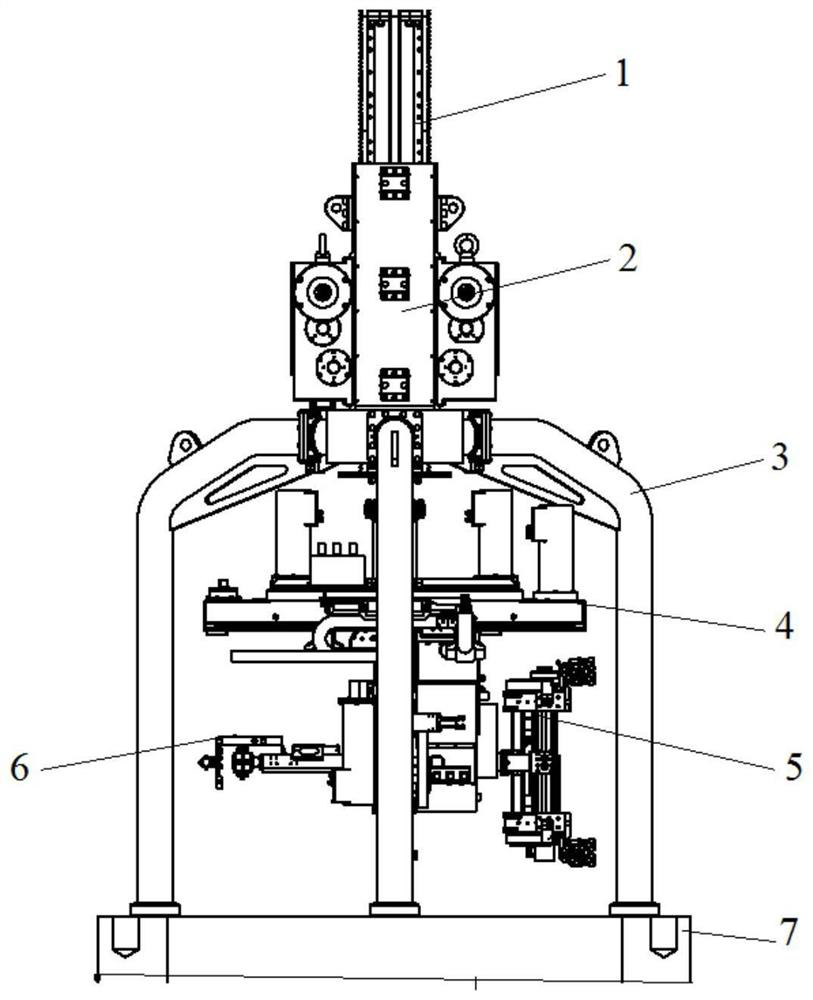

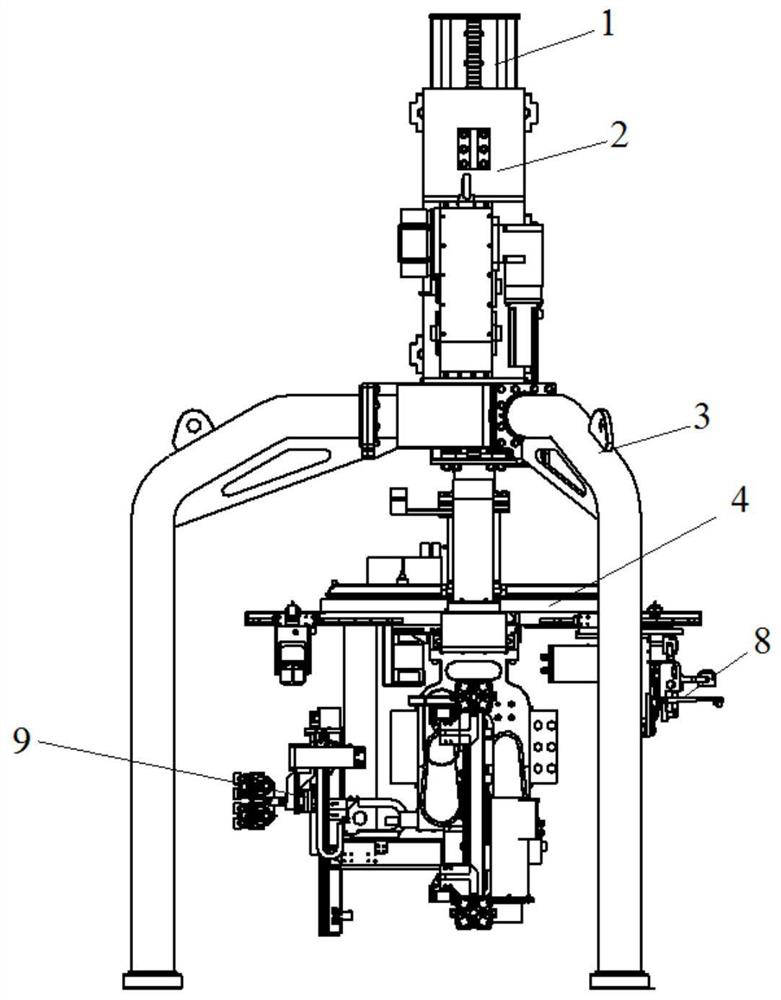

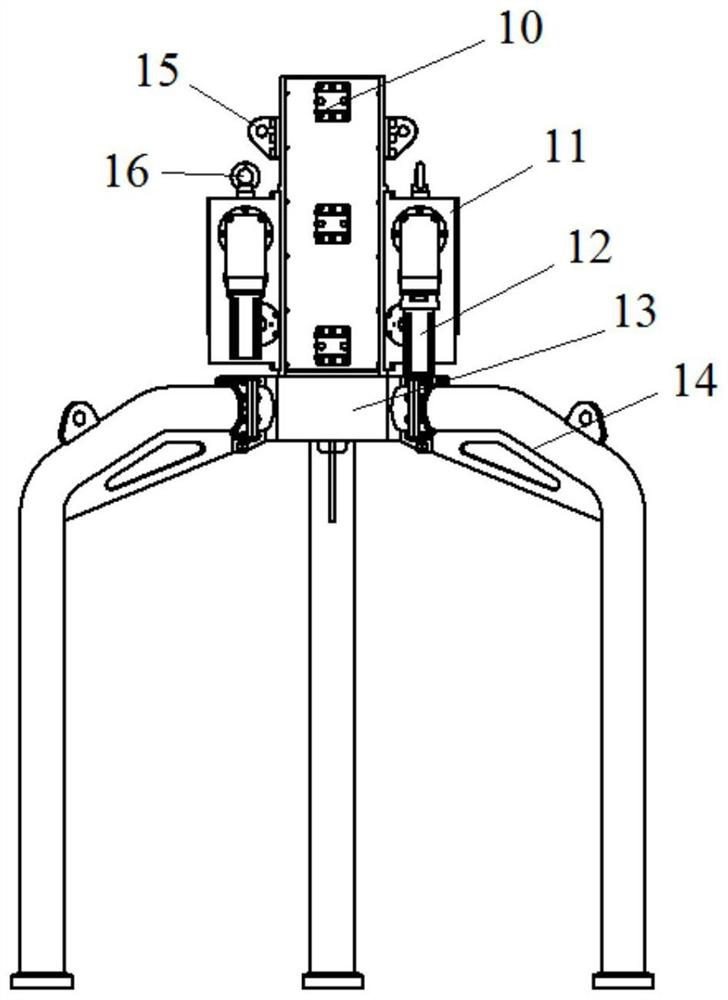

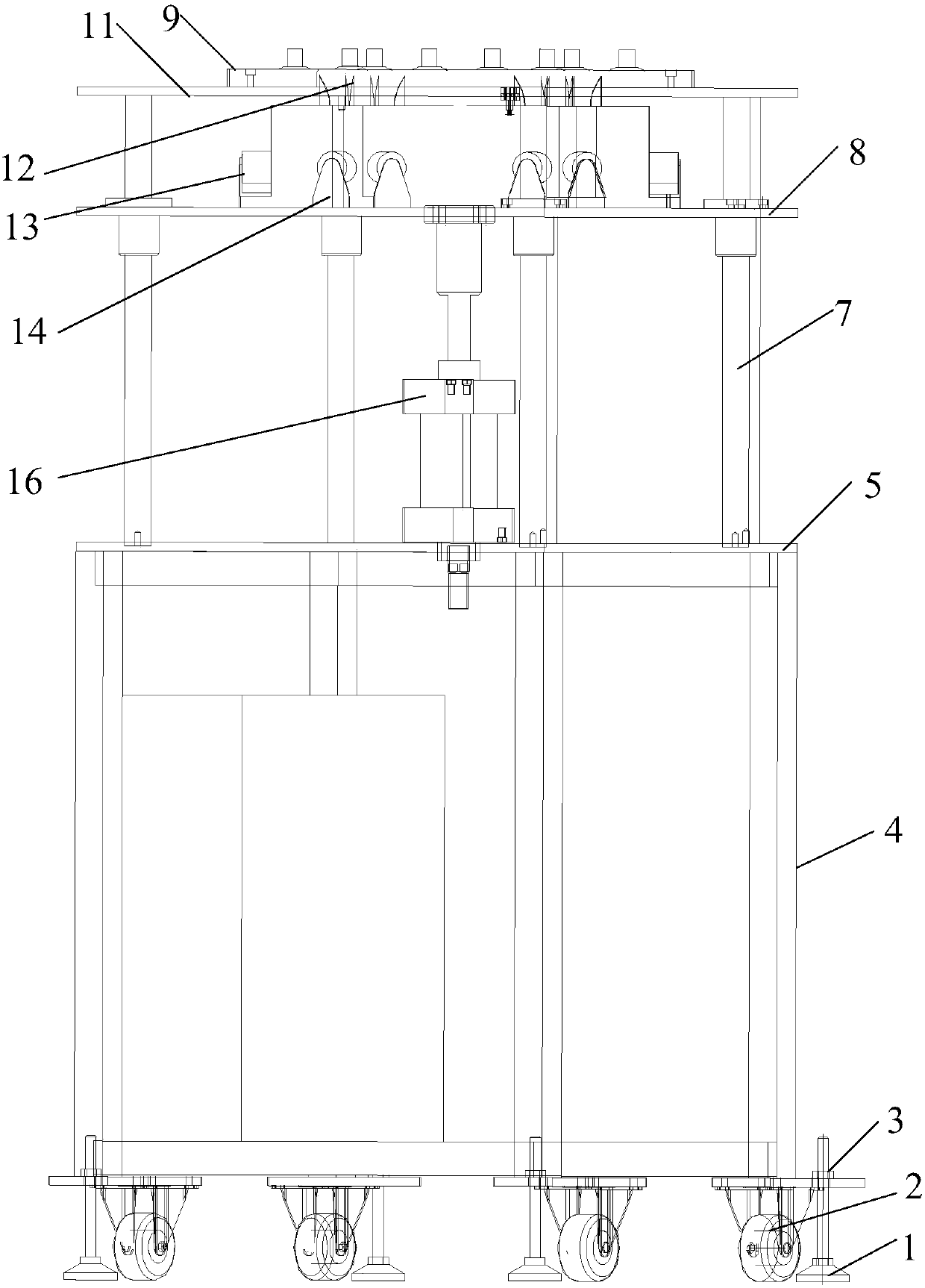

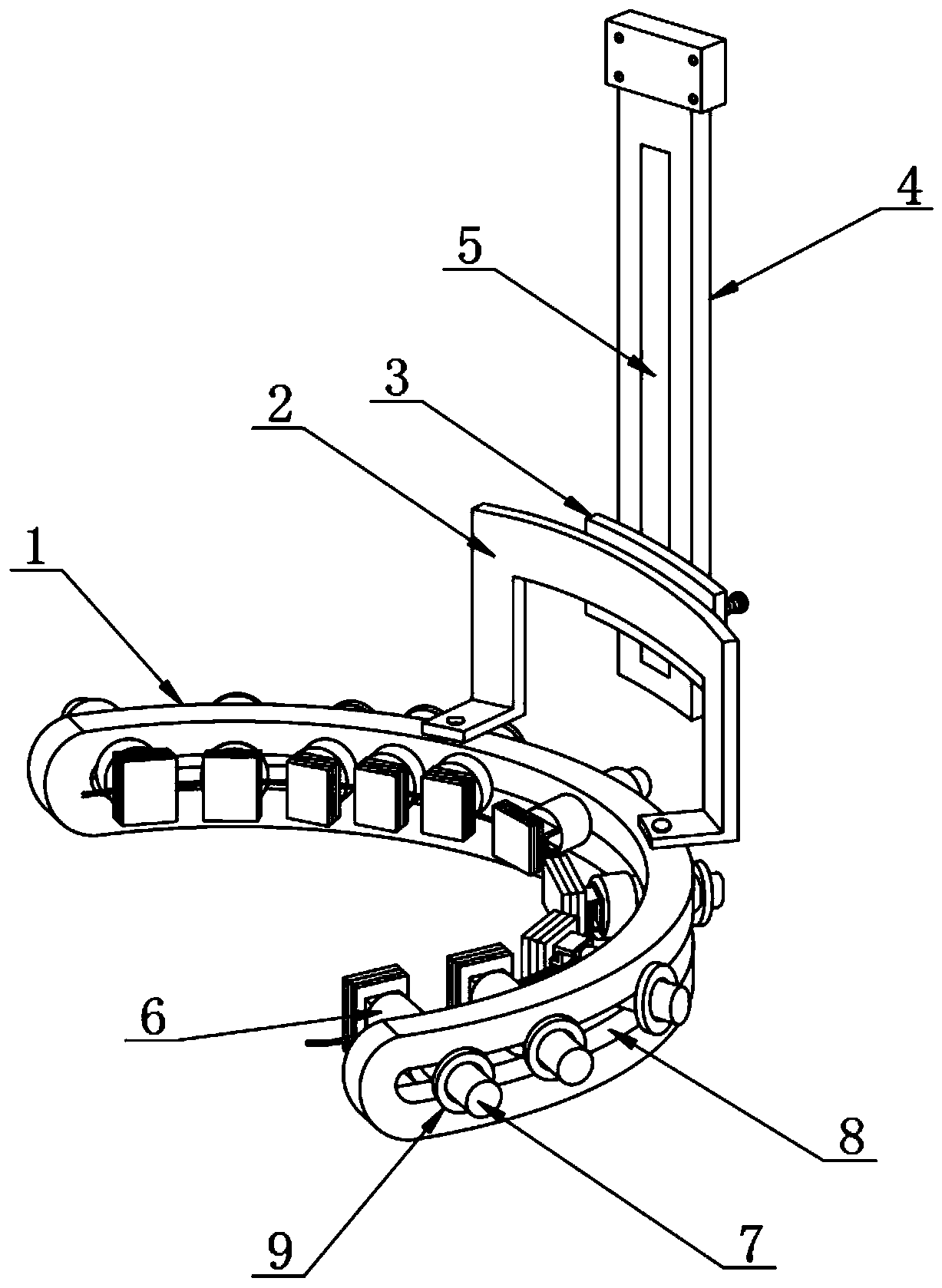

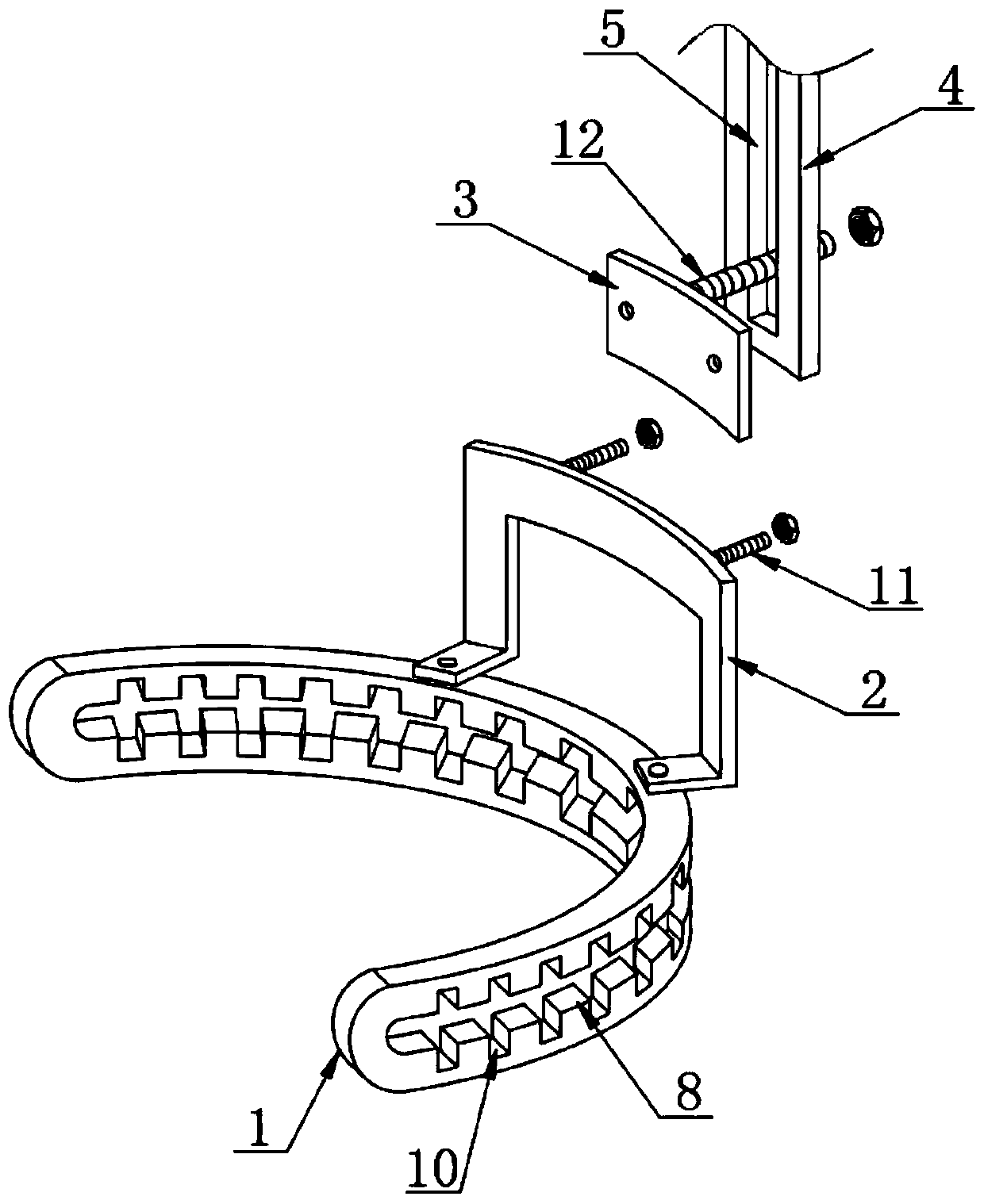

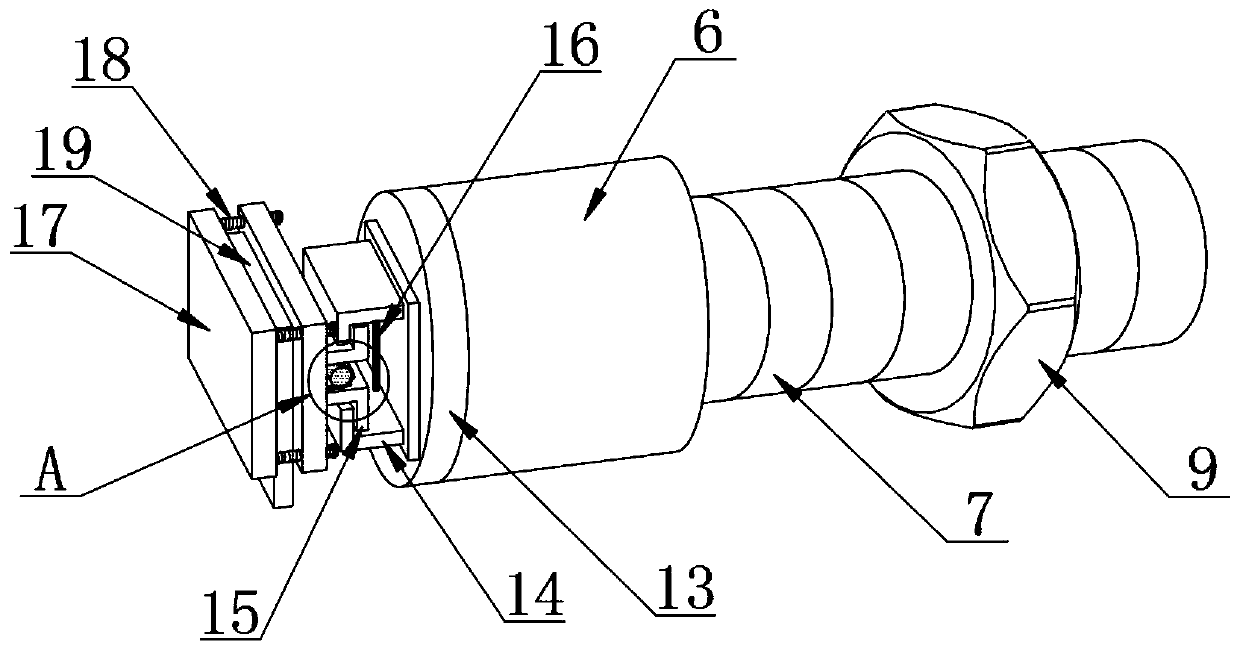

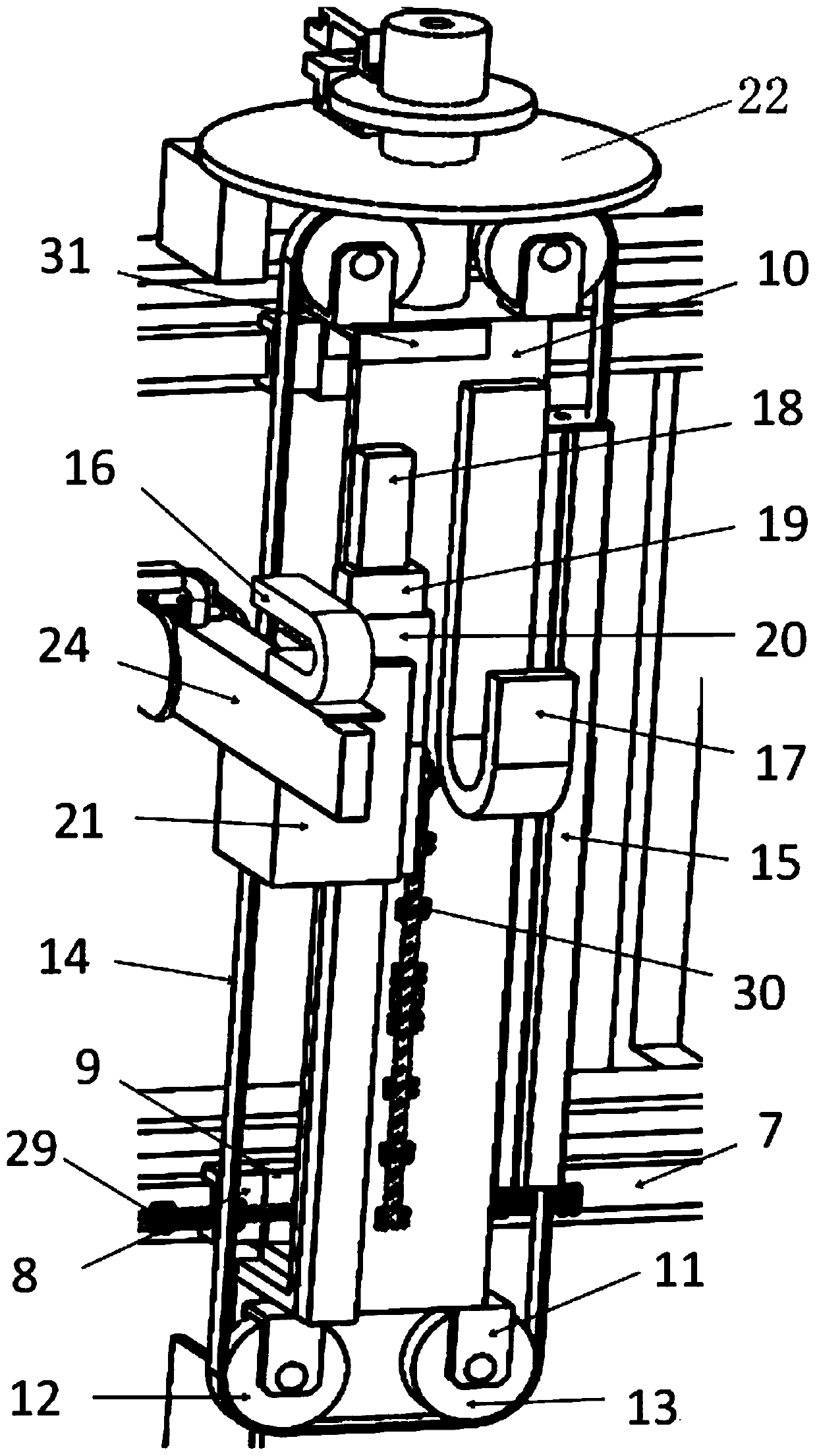

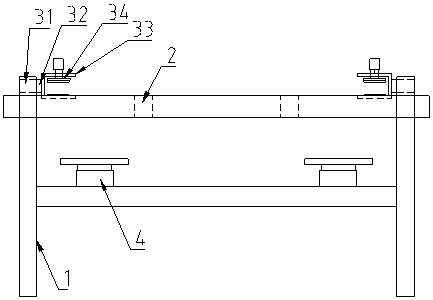

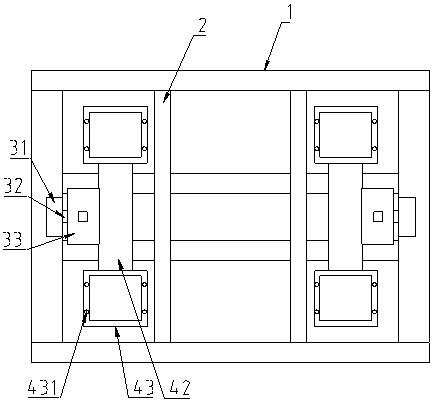

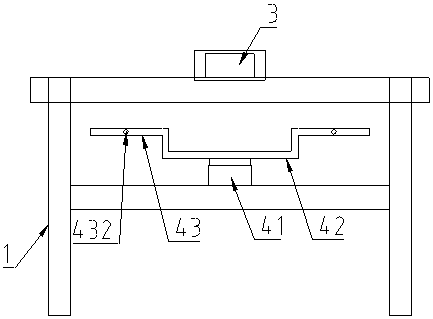

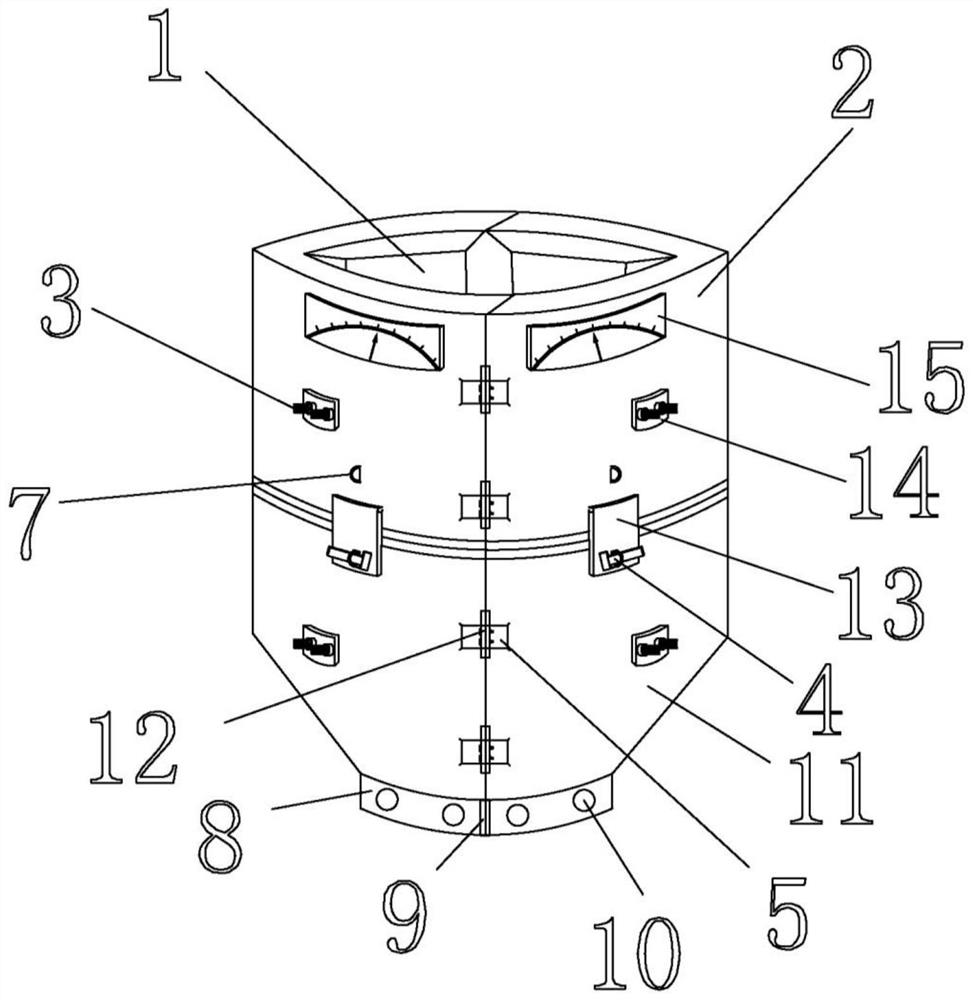

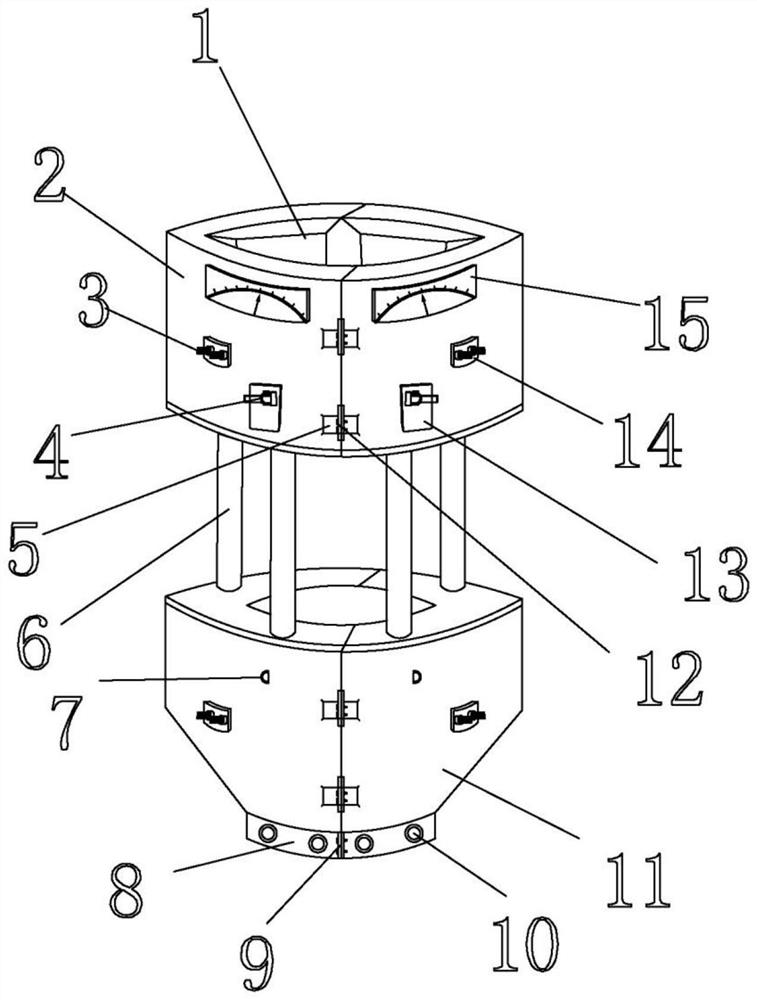

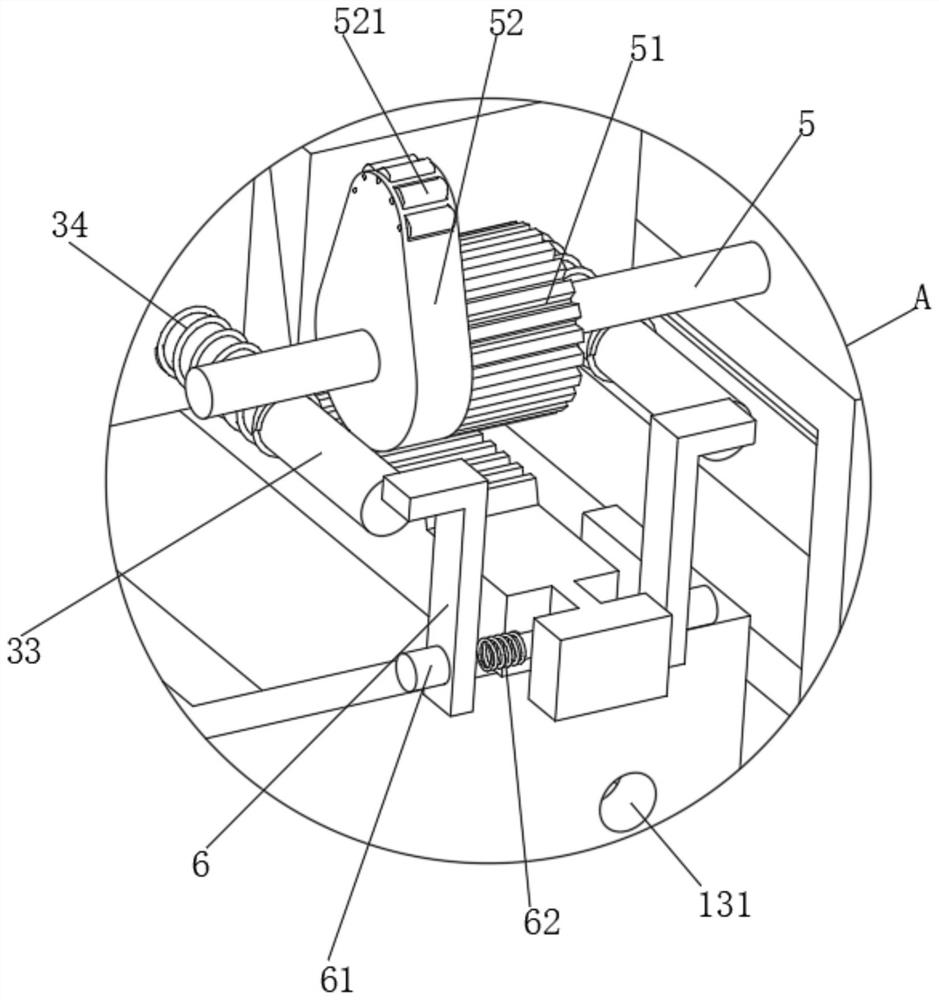

Nondestructive testing device for pressure vessel of nuclear power unit

PendingCN113281412AGuaranteed annual transmission accuracyHigh transmission reliabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesNuclear powerStructural engineering

The utility model relates to the field of machinery and particularly relates to a nondestructive testing device for a pressure vessel of a nuclear power device. An existing pressure container is long in inspection period, the number of times of water lifting and water entering of equipment is large, and dependence on a ring crane is high. The device comprises a lifting stand column, a lifting guide mechanism, a supporting rack, a rotary motion platform, a barrel connecting pipe connection welding seam tangential inspection tool, a connecting pipe internal composite inspection tool, a connecting pipe inner fillet inspection tool and a pressure container barrel inspection tool, wherein the lifting stand column penetrates through the lifting guide mechanism, and the lifting guide mechanism is connected with the supporting rack; the lifting guide mechanism is arranged in the center above the supporting rack, and the lifting stand column is arranged in the middle of the supporting rack and the lifting guide mechanism. According to the device, full-range ultrasonic nondestructive detection of the nuclear power plant pressure vessel is realized, and accurate and efficient detection of the nuclear power plant is realized.

Owner:RES INST OF NUCLEAR POWER OPERATION

Device for cold cutting of pouring gate of molded outside plastic product

The invention discloses a device for cold cutting of pouring gate of a molded outside plastic product. A lower fixed plate is mounted on a fixed bracket. Guide posts are distributed on the lower fixedplate. A supporting plate is arranged on the guide posts through guide holes in the supporting plate. An upper fixed plate is mounted at the top ends of the guide posts. A jig plate is arranged on the upper fixed plate. Supporting frames are mounted on the supporting plate. A pair of scissors is mounted on each supporting frame. A driving unit is in drive connection with the scissors. A lifting cylinder is mounted on the lower fixed plate. A piston rod of the lifting cylinder is in drive connection with the supporting plate. The device can be convenient to move, quick to position and fix, canbe used for automatically fixing a product, and achieves automatic induction and automatic shearing and quick cooling of the pouring gate automatically. Full automatic shearing is conducted after a manipulator of the product is taken out, so that the amount of trimming personnel is reduced, and the production efficiency is improved.

Owner:苏州川鹏塑料有限公司

AGV-based automatic carrying system and multi-AGV cooperation method

ActiveCN113277275AFast positioning and fixingEffective ejectCleaningControl devices for conveyorsRobot handAutomatic control

The invention discloses an AGV-based automatic carrying system, and belongs to the technical field of AGVs. The AGV-based automatic carrying system comprises an AGV, an extrusion assembly, a moving track, a track base, a trigger assembly, a cleaning assembly, a vibration component, a driving assembly and a transfer assembly, the moving track is fixedly mounted on the top of the track base, and the AGV is slidably mounted on the moving track; According to the AGV-based automatic carrying system, an infrared sensor is installed outside, the transfer assembly is installed inside, when the AGV runs normally, the infrared sensor can effectively detect the distance between the AGV and a front vehicle, when the distance reaches a set value, the front vehicle can automatically control to start a driving motor, and the driving motor can drive the transfer assembly to send out; and due to the fact that a connecting spring cushion is arranged outside the transfer assembly, when a first transfer plate of the transfer assembly is completely conveyed out of a vehicle body, the first transfer plate can be automatically bent, at the moment, a worker or a mechanical arm can quickly transfer goods on the vehicle body to the front vehicle, and the cooperative work effect of the multiple AGVs is effectively achieved.

Owner:福建中科兰剑智能装备科技有限公司

Trachea cannula positioning device for intensive care units

PendingCN113117204AFast positioning and fixingAvoid harmTracheal tubesInjury causeTracheal cannulation

Owner:江西省中西医结合医院

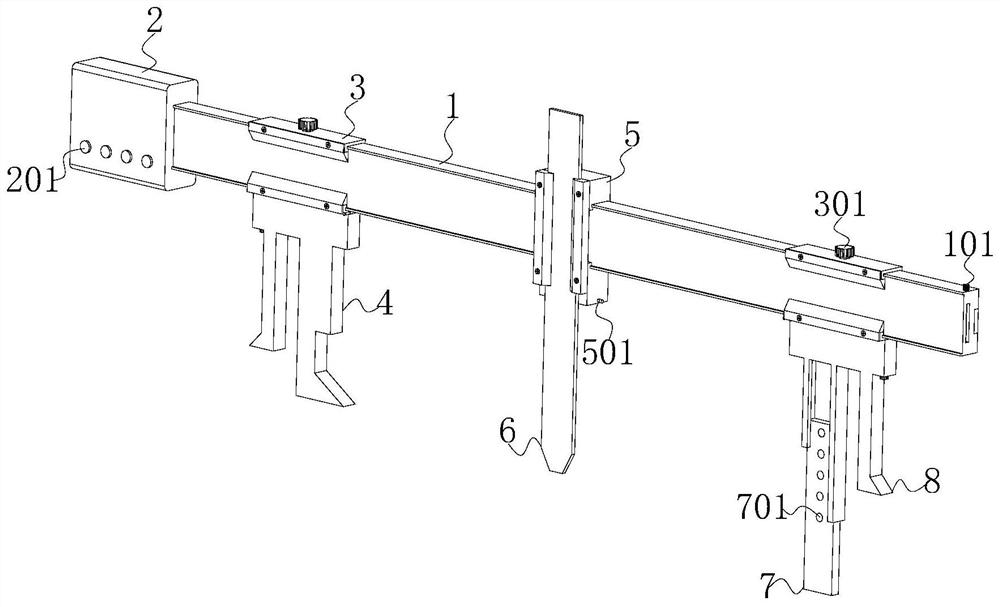

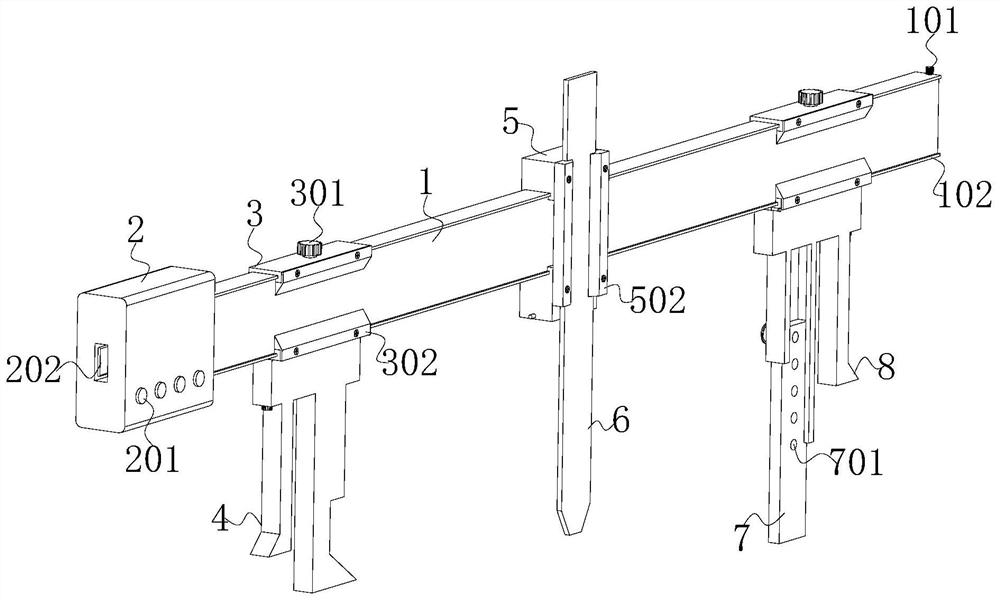

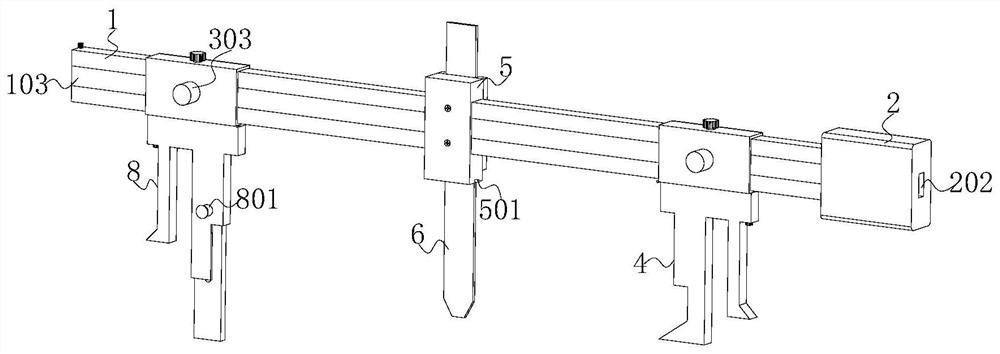

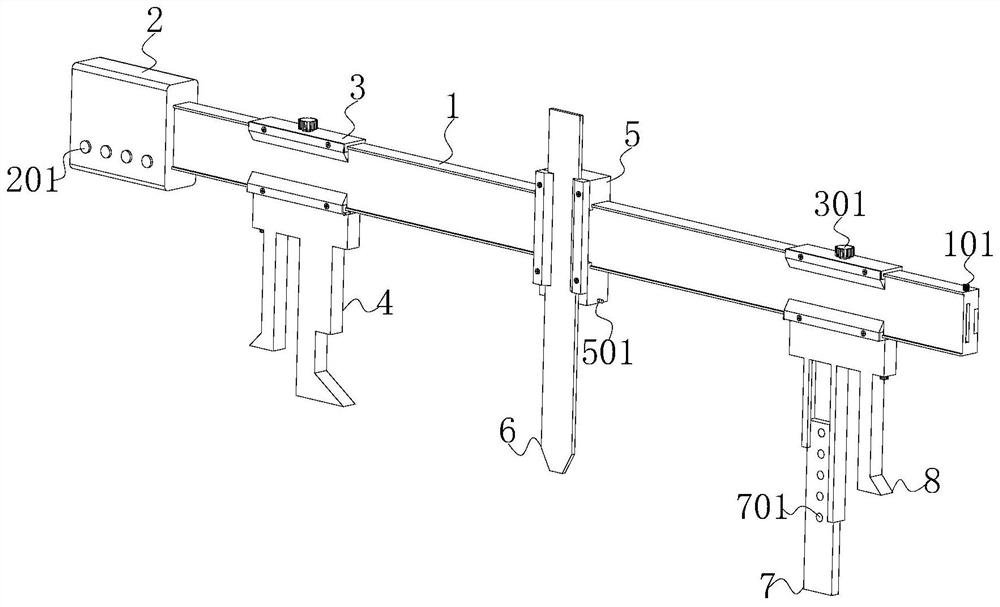

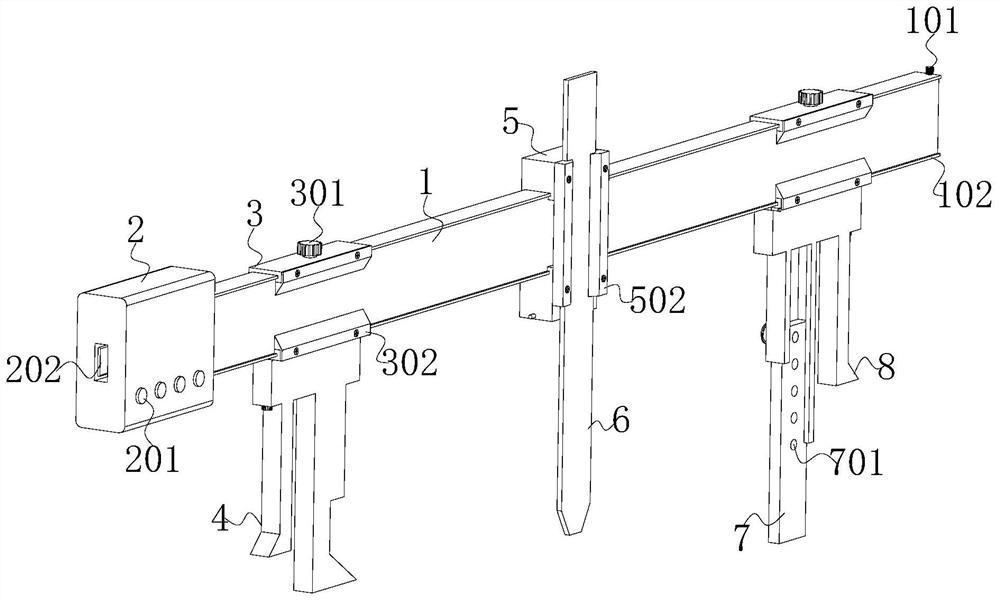

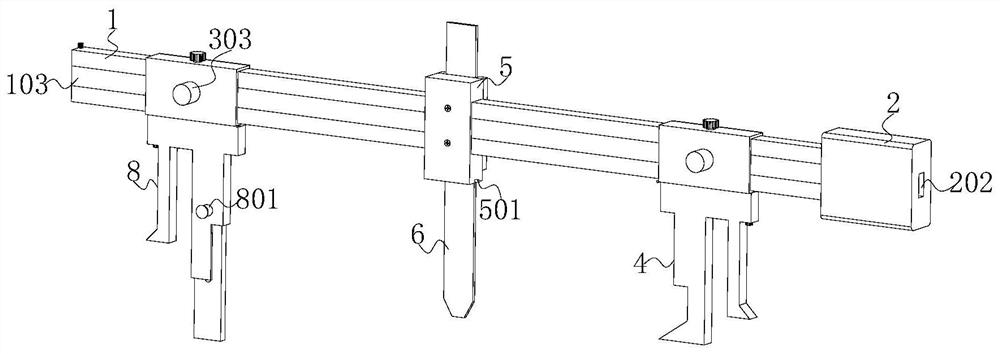

Line steel rail frog abrasion inspection ruler

ActiveCN111928752AFast positioning and fixingEfficient and convenient adjustment processMechanical measuring arrangementsRailway auxillary equipmentRail inspectionStructural engineering

The invention discloses a line steel rail frog abrasion inspection ruler, and relates to the technical field of line steel rail inspection. The ruler comprises a ruler plate, a control box, a first adjusting frame and a second adjusting frame, the middle of the ruler plate is fixedly sleeved with the second adjusting frame, and the parts, on the two sides of the second adjusting frame, of the ruler plate are symmetrically and slidably matched with the first adjusting frame; one end surface of the ruler plate is fixedly connected with a control box, wherein a first measuring frame and a secondmeasuring frame are respectively and fixedly arranged on the bottom surfaces of the two first adjusting frames in a matched manner, and a first measuring ruler is arranged on the second adjusting frame in a matched manner; an iron bar is fixedly clamped in the middle of the rear side face of the ruler plate in the extending direction of the ruler plate. Through the arrangement of the first electromagnetic column, the control box, the second electromagnetic column, the iron bar, the permanent magnetic column, the first abutting column, the placing groove, the first rotating sleeve, the second rotating sleeve, the rotating column, the second abutting column and the quantitative hole, the device is more efficient and convenient in measurement adjustment process, good in folding and storage effect and more efficient and accurate in positioning of the measuring ruler at the one-third position of the rail surface.

Owner:SHANDONG LINQU SLEEPER

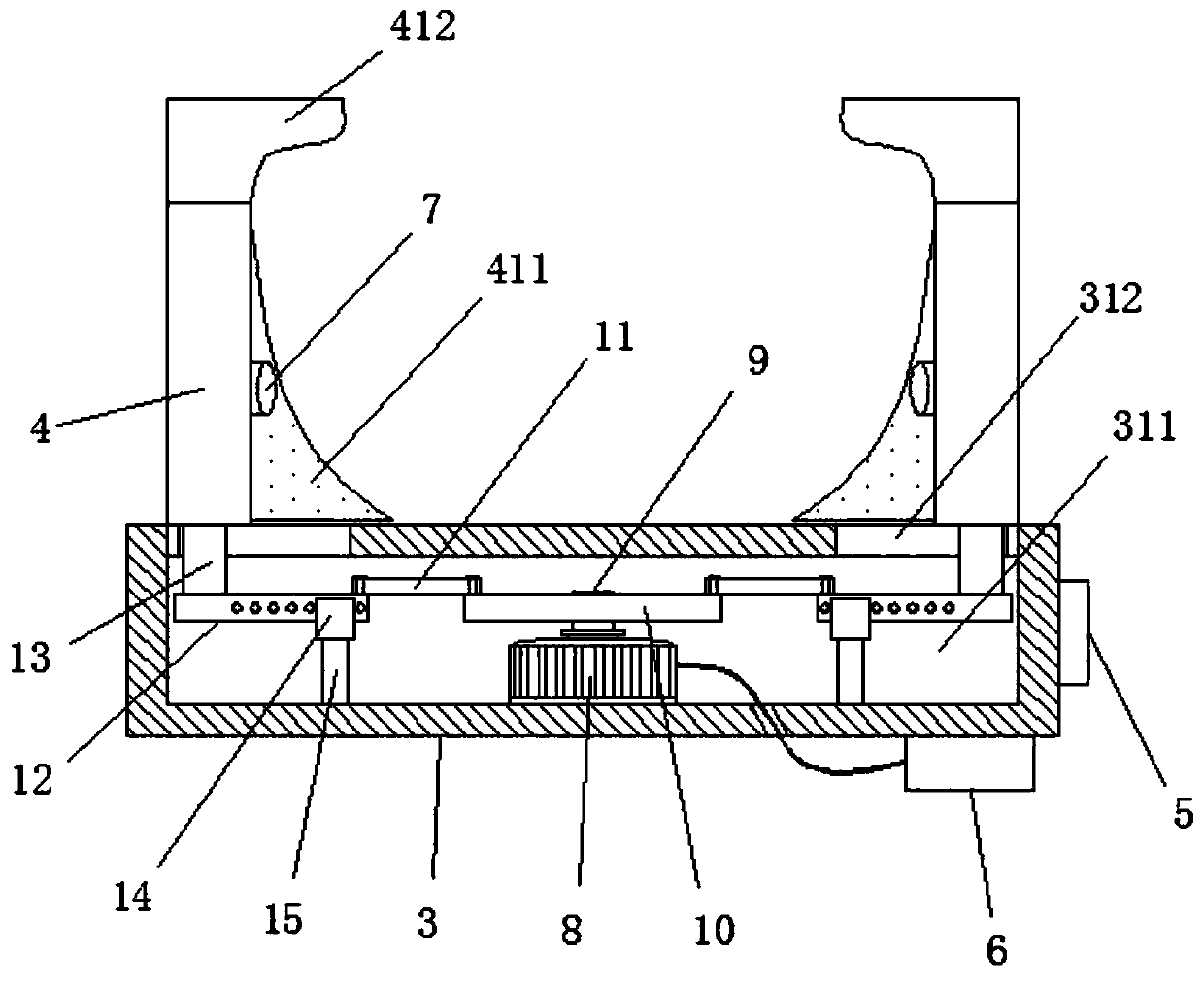

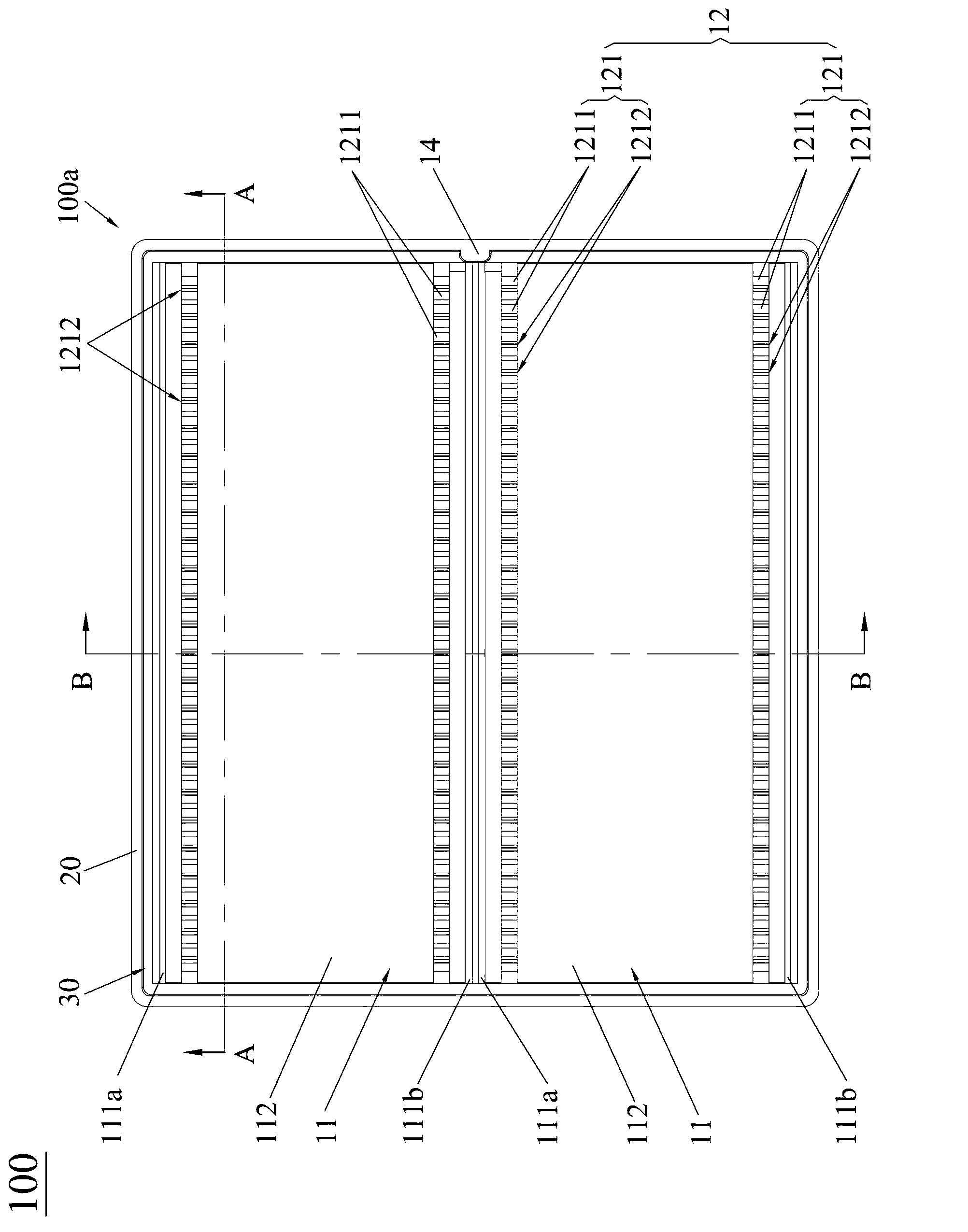

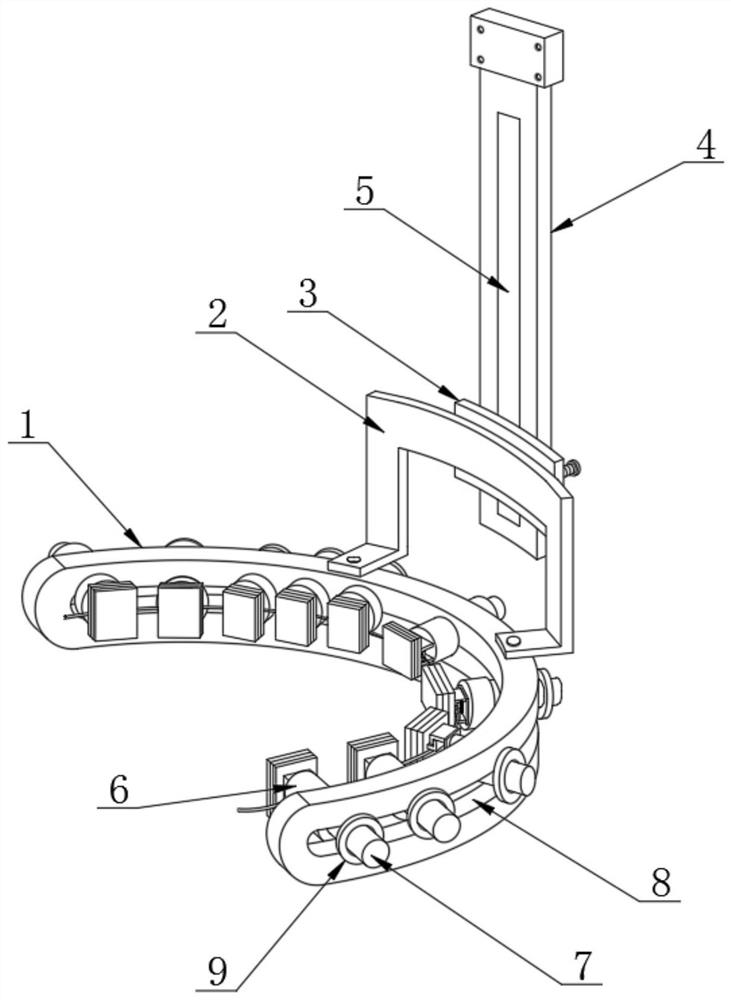

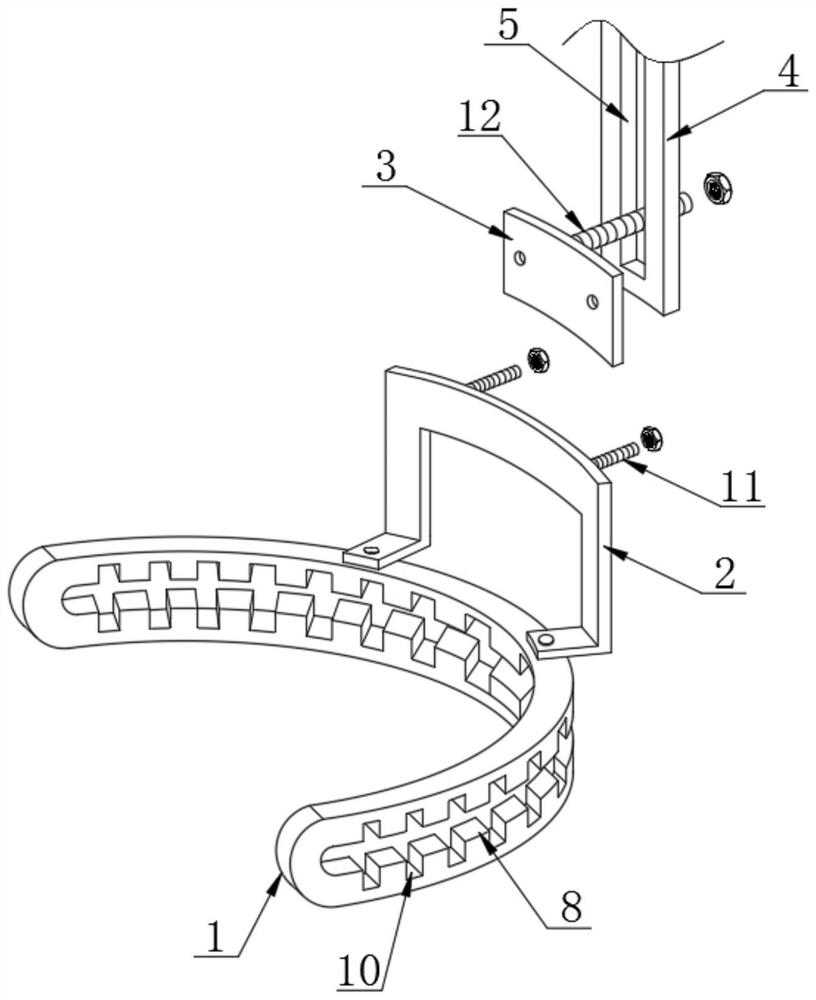

Orthodontic force measuring equipment for tooth correction

The invention discloses orthodontic force measuring equipment for tooth correction, and relates to the technical field of tooth correction. The orthodontic force measuring equipment for tooth correction comprises an arc-shaped frame, wherein the upper end of the arc-shaped frame is connected with a connecting support frame; the outer side surface of the upper end of the connecting support frame isconnected with an adjusting plate; the outer side surface of the adjusting plate is connected with a connecting plate; the middle part of the connecting plate is provided with an adjusting groove; the middle part of the surface of the arc-shaped frame is provided with a transverse groove; and vertical grooves are correspondingly formed in the surface of the arc-shaped frame and are positioned atthe upper end and the lower end of the transverse groove. According to the orthodontic force measuring equipment, the adjusting plate, a transverse adjusting rod and a longitudinal adjusting rod are used for cooperation; in addition, the vertical grooves cooperate with the transverse groove, so that the adjustment of a measuring mechanism is more accurate; and meanwhile, the arch wire clamping plate is matched with the effects of reset springs and slide blocks, so that the fast positioning and fixation on an arch wire is realized. The problems of binding complexity and insufficient binding firmness during the arch wire fixation by a traditional measuring device are solved, so that the accuracy and the efficiency of the tooth orthodontic force measurement are improved.

Owner:陈昕

Workpiece storing container

InactiveCN103223663AQuick storageFast positioning and fixingWork tools storageEngineeringMechanical engineering

The invention discloses a workpiece storing container, which comprises container bodies adopting hollow structures, wherein the hollow structures penetrate through the top ends of the container bodies to form storing cavities; two corresponding side surfaces of each storing cavity are arranged in the direction from the bottom end of each container body to the top end of each container body and in a manner of enlarging the distance between the two side surfaces; and a positioning part for inserting, clamping and positioning a workpiece is arranged on the bottom surface of each storing cavity and positioned between every two side surfaces. During the use, when the bottom end of the workpiece is horizontally inserted and clamped onto the positioning part, the two sides of the workpiece can be butted and fixedly positioned between the two side surfaces. The workpiece storing container provided by the invention facilitates the storage of the workpiece and has the advantage of simple structure.

Owner:任向荣

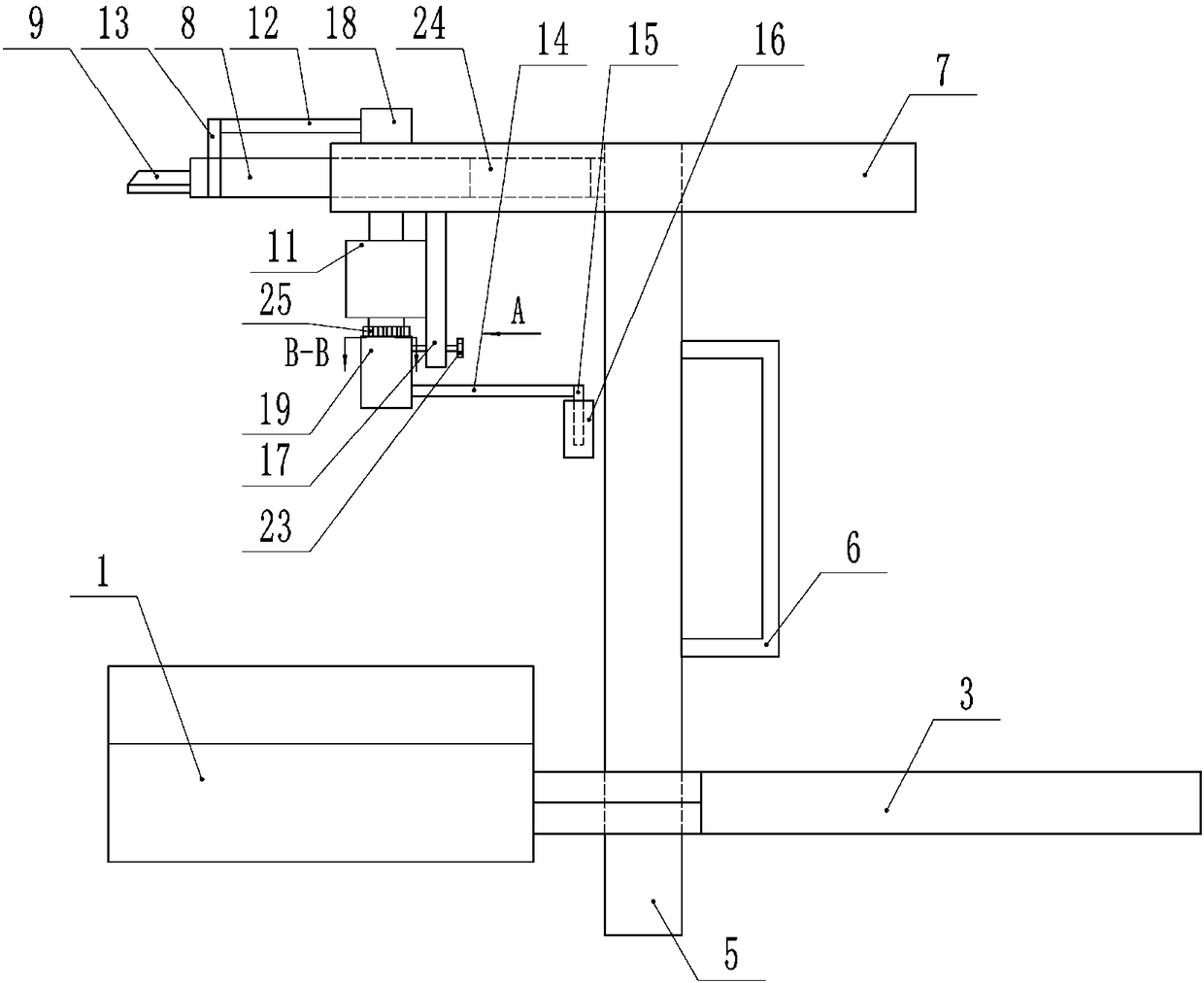

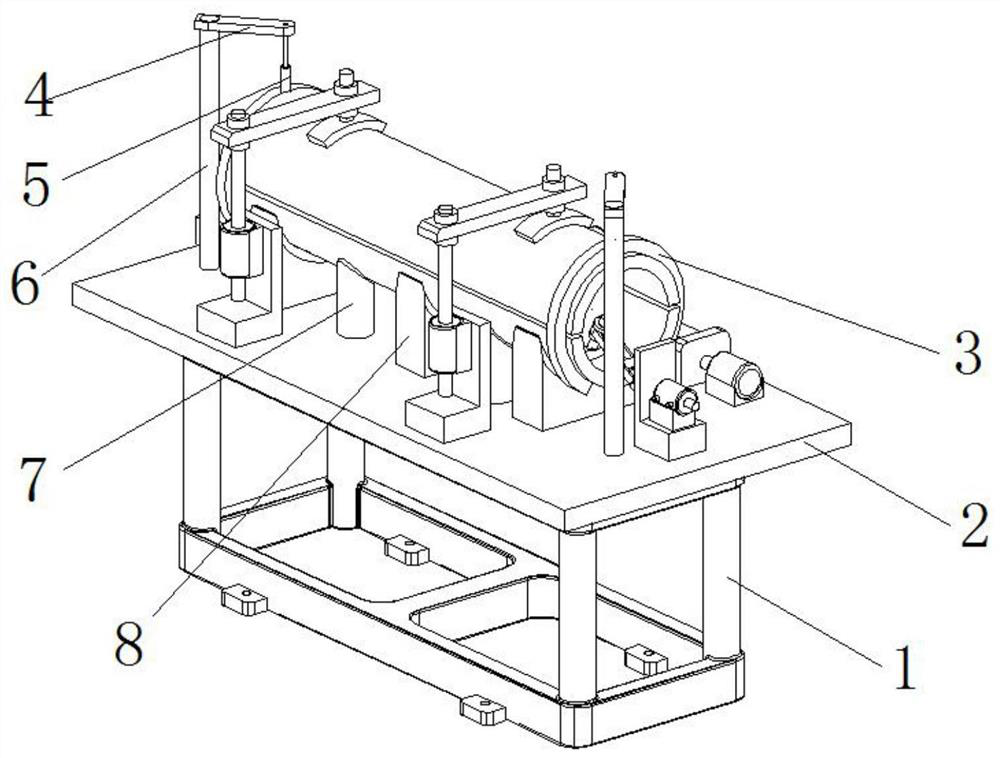

Skin piece perforating device

PendingCN110170678AFast positioning and fixingSatisfy hole making requirementsBoring/drilling machinesDrillOperation safety

The invention relates to a skin piece perforating device. The skin piece perforating device comprises a frame, and a horizontal adjusting mechanism, a vertical adjusting mechanism, a drill fine adjustment mechanism and a drill arranged on the frame; multiple elbow clamps are arranged on one side of the frame for clamping and fixing skin pieces; the horizontal adjusting mechanism is arranged on theother side of the frame; the vertical adjusting mechanism is arranged on the horizontal adjusting mechanism, and can horizontally move in the longitudinal direction of the frame along with the horizontal adjusting mechanism; the drill fine adjusting mechanism is arranged on the vertical adjusting mechanism, and can vertically move in the height direction of the frame along with the vertical adjusting mechanism; and the drill is arranged on the drill fine adjustment mechanism, and can move in the transverse direction of the frame along with the drill fine adjustment mechanism and horizontallyswing. The skin piece perforating device is simple in structure and operation method and excellent in generality, can improve the skin piece perforating precision and efficiency, and improves the operation safety.

Owner:UNIV OF SCI & TECH LIAONING

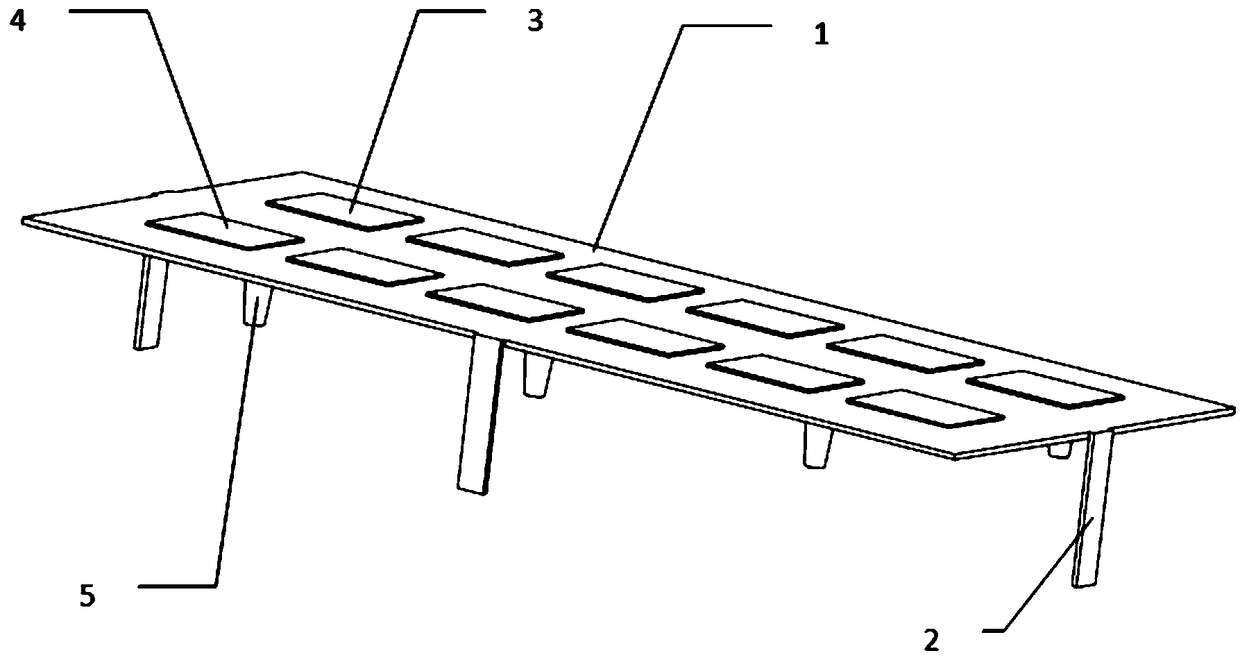

Glass cutting location supporting platform

PendingCN108439783AFast positioning and fixingPrecise positioningGlass severing apparatusMechanical engineeringEngineering

The invention discloses a glass cutting location supporting platform which comprises a support, an accommodating plate, clamping devices and a fixing device, wherein the accommodating plate is arranged in a top framework of the support, the clamping devices are arranged on the two sides of the support, and the fixing device is arranged in the middle of the support; each clamping device comprises afixed seat, an electric telescopic rod, a clamping plate and a downward pressing plate, the fixed seat is arranged on the support, the electric telescopic rod is arranged on the inner side of the fixed seat, the electric telescopic rod is fixedly connected with the clamping plate, and the downward pressing plate is further arranged in the clamping plate; the fixing device comprises a lifting base, a connection plate and material receiving frames, the lifting base is arranged in the middle of the support, the connection plate is fixedly arranged at the top end of the lifting base, the materialreceiving frames are fixedly connected to the two ends of the connection plate, air sucking holes are arranged on the top surfaces of the material receiving frames, venting holes are arranged on thelateral edges of the material receiving frames, and the venting holes are connected with air pipes. The glass cutting location supporting platform disclosed by the invention has the advantages of quickness in location, firmness in fixing, small cutting vibration, high cutting efficiency, safety and reliability.

Owner:王振宇

Super high-rise steel column welding positioning adjusting fixator

PendingCN111774796AImprove install rateOvercome errorWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsStructural engineering

The invention discloses a super high-rise steel column welding positioning adjusting fixator. The super high-rise steel column welding positioning adjusting fixator comprises an upper fixing adjusterand a lower fixator body, before installation and use, the upper fixing adjuster and the lower fixator body are connected in the horizontal direction by adopting a fixing buckle plate and a fixing bolt and fixed through a fixing clamp, the upper fixing adjuster itself and the lower fixator body itself are fixed in the vertical direction through a connecting plate and a fixing clamping plate by connecting bolts, a hydraulic piece is arranged in the upper fixing adjuster to achieve adjustment and fixation, a built-in jack is arranged in the lower fixator body to realize adjustment and fixation,during the use and installation, and an adjustable fixing rod is arranged between the upper fixing adjuster and the lower fixator body to fix the length according to actual installation requirements.According to the super high-rise steel column welding positioning adjusting fixator, the steel column installation speed can be increased, the problems of steel column installation deviation errors and repeated checking in the prior art are solved, and good construction conditions can be created for installation and construction of the super high-rise engineering steel columns.

Owner:CHINA CONSTR FOURTH ENG DIV

An orthodontic force measuring device for orthodontics

The invention discloses an orthodontic force measuring device for orthodontics, which relates to the technical field of orthodontics, and comprises an arc-shaped frame. The outer surface of the adjusting plate is connected with a connecting plate, the middle part of the connecting plate is provided with an adjusting groove, the middle part of the surface of the arc-shaped frame is provided with a transverse groove, and the surface of the arc-shaped frame is located at the upper and lower ends of the transverse groove Correspondingly, a vertical groove is provided. The present invention adopts the cooperation of the adjustment plate, the horizontal adjustment rod and the longitudinal adjustment rod, and the cooperation of the vertical groove and the horizontal groove, so that the adjustment of the measuring mechanism is more accurate. The rapid positioning and fixing of the arch wire solves the problems of cumbersome binding and insufficient binding of the traditional measuring device when the arch wire is fixed, thereby improving the accuracy and efficiency of orthodontic force measurement.

Owner:陈昕

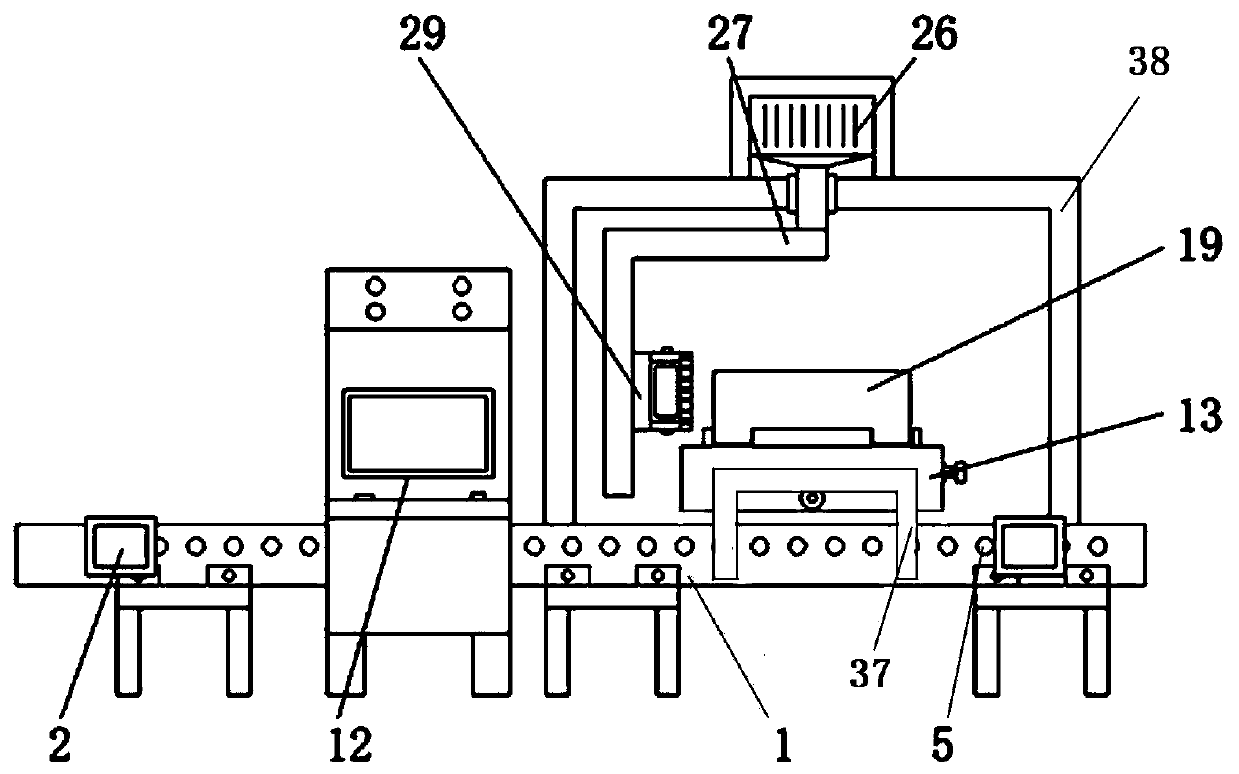

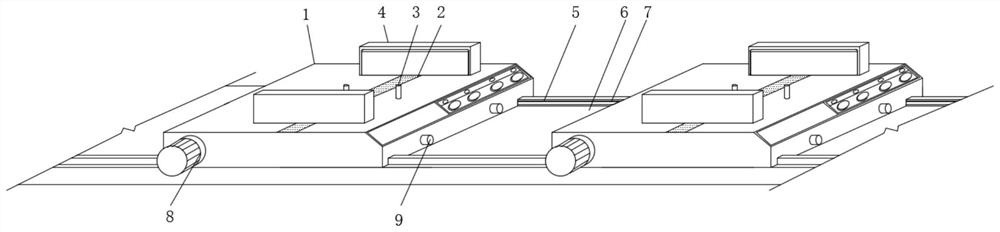

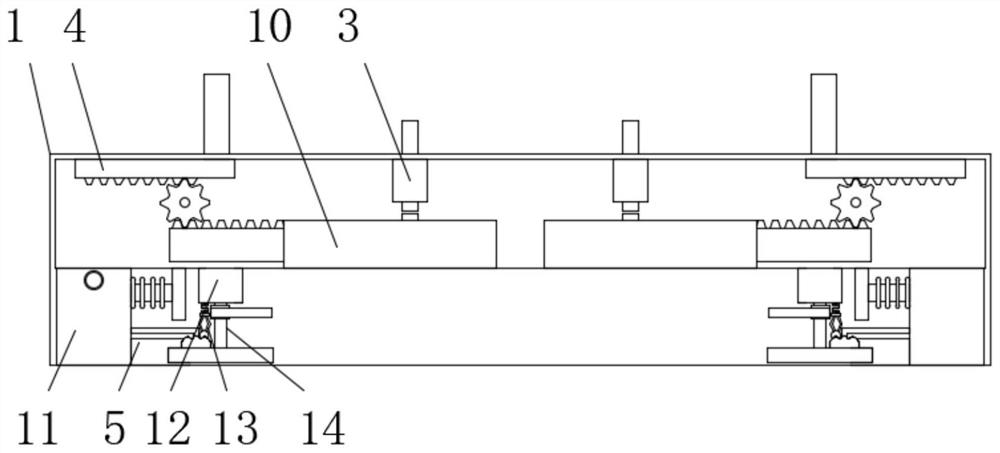

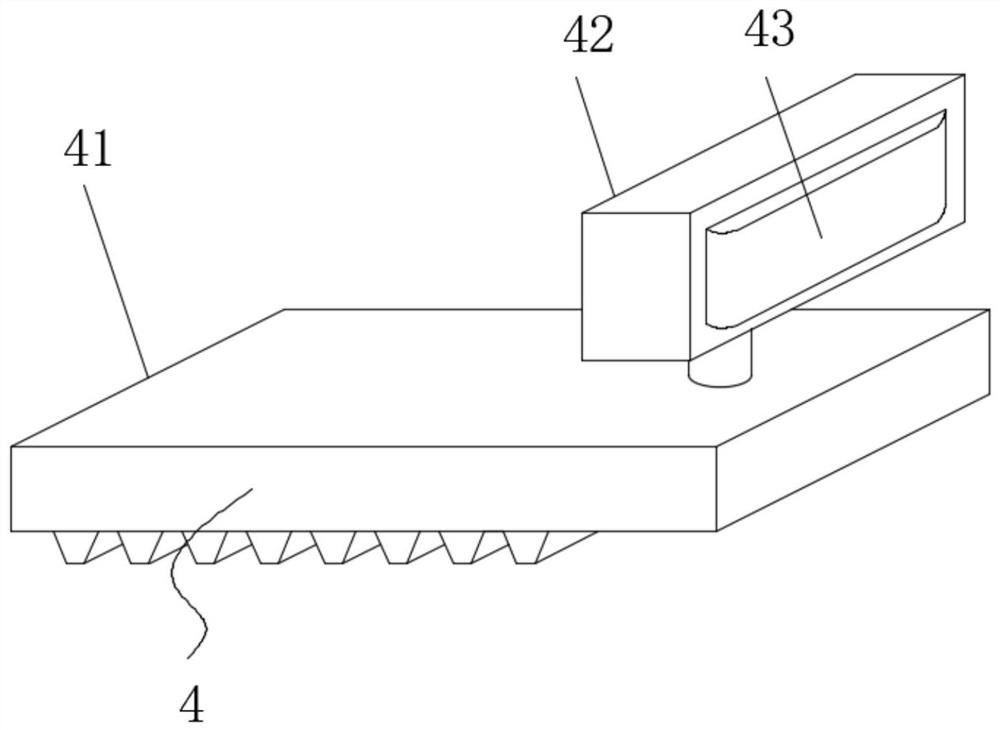

Assembly type floor sound insulation material production line

ActiveCN113977674AFast positioning and fixingGuaranteed stabilityMetal working apparatusEngineeringAcoustics

The invention relates to the technical field of sound insulation materials, in particular to an assembly type sound insulation material production line which comprises a cutting device, a limiting plate is fixedly welded to one end of the cutting device, a moving groove is formed in the end, away from the limiting plate, of the cutting device, and a dovetail rail is fixedly welded to the interior of the moving groove. A fixing plate is welded and fixed to the upper end of the end opening of the moving groove, and guide holes are symmetrically formed in the fixing plate; through arranged locking plate, first clamping plate can be pulled to move towards one side close to floor sound insulation plate, then gear is driven to rotate under action of rack on first clamping plate, second clamping plate also moves towards one side close to floor sound insulation plate under action of cam, and then two clamping plates move oppositely to clamp floor sound insulation plate. And meanwhile, a pressing plate moves downwards to press the floor acoustic panel under the action of an inclined plane ejector block, so that the floor acoustic panel can be quickly positioned and fixed, the stability of the floor acoustic panel in the cutting process is guaranteed, and the cutting efficiency is greatly improved.

Owner:重庆易高实业有限公司

Cutting device for non-woven fabric production

InactiveCN110528259AFast and stable installation and positioning operationStable positioning operationSevering textilesPulp and paper industryNonwoven fabric

The invention discloses a cutting device for non-woven fabric production. The cutting device comprises a non-woven fabric cutting machine body, a servo motor and a functional bearing, wherein a base plate is fixed to the edge side of the non-woven fabric cutting machine body, the top of a supporting plate is fixed to the outer ring of the functional bearing, and the inner ring of the functional bearing is fixed to a connecting column. The connecting column penetrates through a limiting window, the limiting window is formed in a vertical plate, the connecting column is mutually connected with apositioning block, and a clamping groove is formed in the positioning block. A control bolt is installed on the top of the positioning block, the bottom of the control bolt is provided with a squeezing block, the squeezing block is arranged in the positioning block, and the edge side of the squeezing block is connected with the inner side of the positioning block. According to the cutting devicefor non-woven fabric production, the novel structural design is adopted, the device can quickly and stably install and position a non-woven fabric roll by using a mechanical structure, a middle shaftof a non-woven fabric roll can be stably and fixedly positioned, manual operation is not required, the efficiency is high, and the safety is high.

Owner:陈学祥

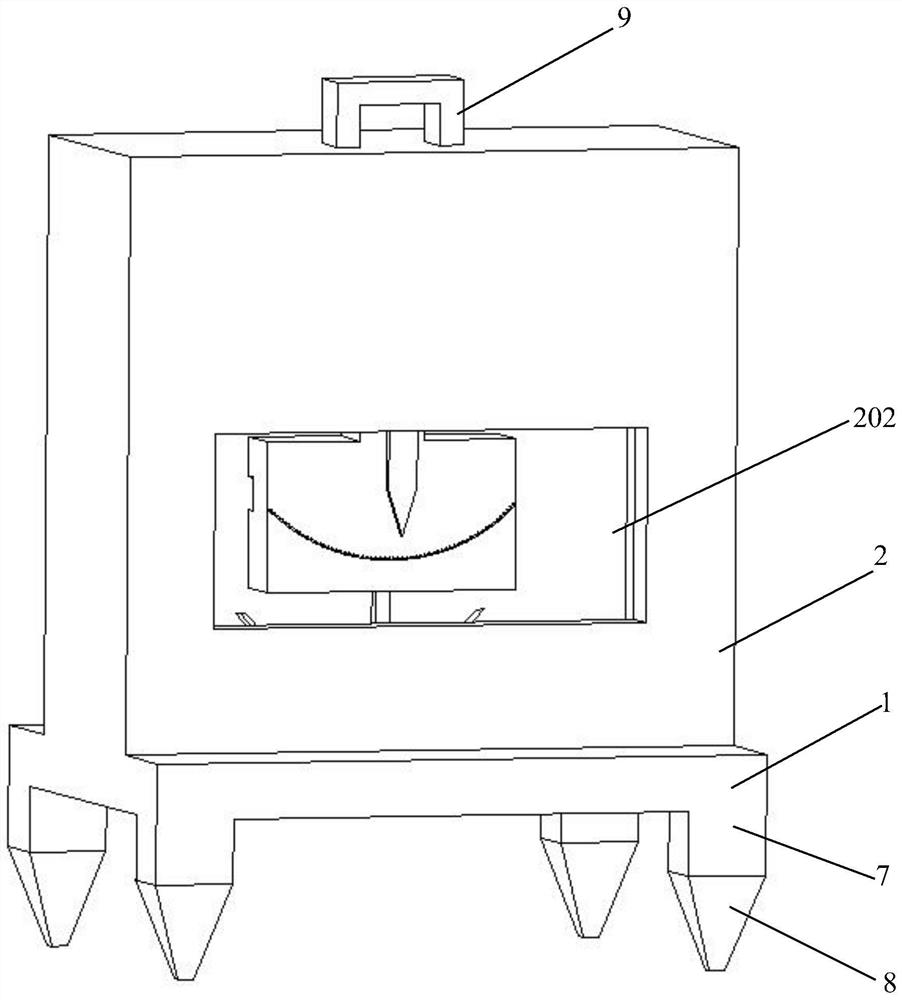

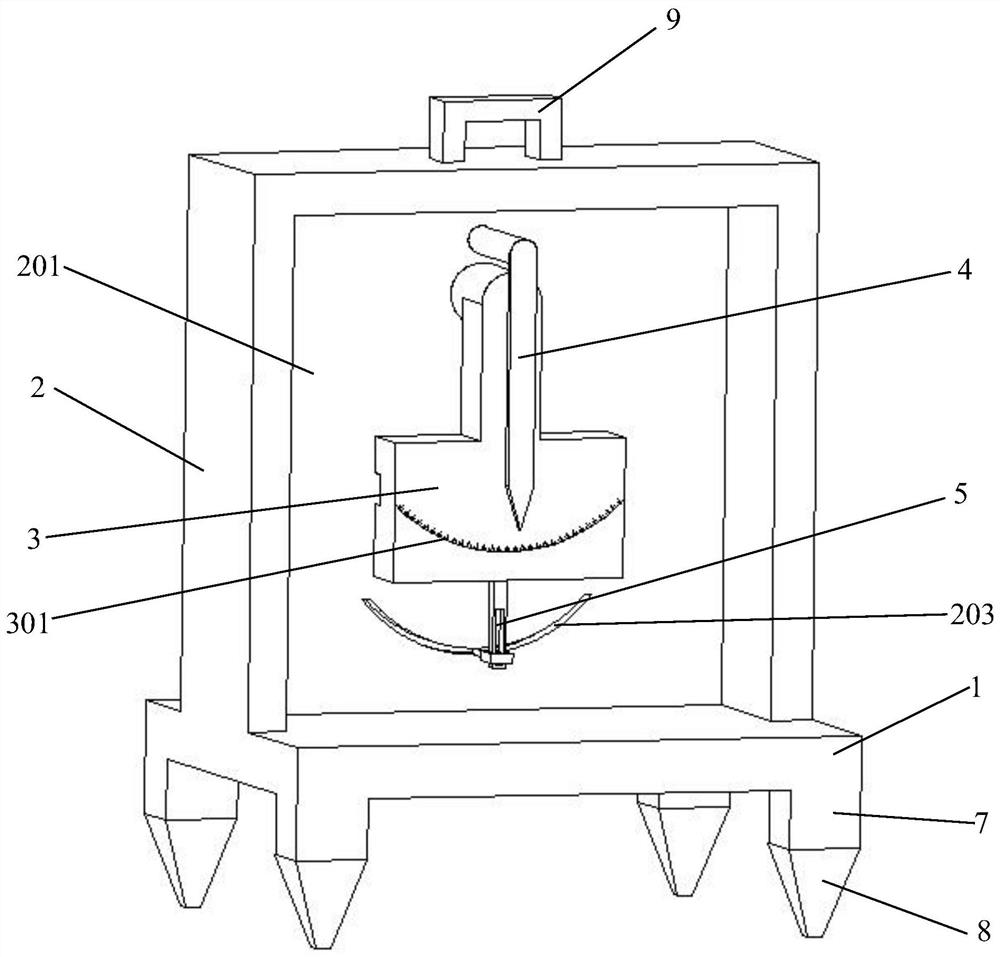

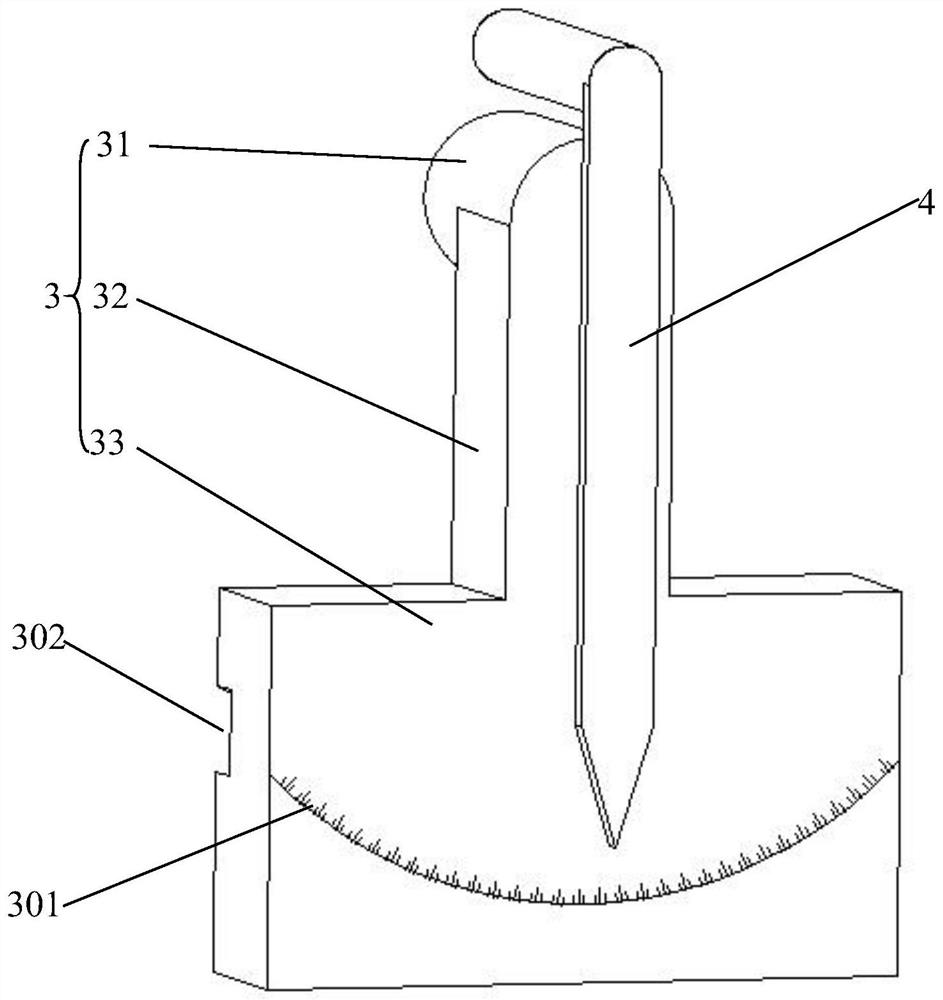

Land gradient measuring device for engineering exploration

ActiveCN112268544AReduce the number of reciprocating swingsShorten the timeIncline measurementClassical mechanicsControl theory

The invention discloses a land gradient measuring device for engineering exploration. The land gradient measuring device comprises a base, a box body, a gradient measurement swing piece, a vertical fixed pointer, a swing limiting piece and a telescopic inserting positioning rod; the bottom end of the box body is fixedly connected with the top end of the base, a containing cavity is formed in the box body, and an observation window is formed in the box body; the gradient measurement swing piece is rotatably arranged on the cavity wall of the containing cavity, gradient scales and an arc-shapedinserting positioning groove are formed in the gradient measurement swing piece, and an arc-shaped swing limiting groove is formed in the cavity wall of the rear side of the containing cavity; the vertical fixed pointer is fixedly connected with the rear side cavity wall of the containing cavity, and the pointer end of the vertical fixed pointer points to the gradient scales; the swing limiting piece is fixedly connected with the bottom end of the slope measuring swing piece; the bottom end of the swing limiting piece is in rolling contact with the arc-shaped swing limiting groove; and the telescopic inserting positioning rod is arranged on the rear side wall of the box body in a penetrating manner and is fixedly inserted into the arc-shaped inserting positioning groove. According to the device, the swing time of the slope measurement swing piece can be shortened, the slope measurement swing piece can be quickly stabilized and can be quickly positioned and fixed, so that quick measurement is realized, and the measurement efficiency is high.

Owner:HEBEI UNIV OF ENG

A bidirectional welding jig for laser welding

ActiveCN111136394BHold down quicklyStay verticalWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser soldering

The invention discloses a dual-way welding clamp for laser welding, and relates to the field of welding tool clamps. The problems that positioning, clamping and assembling effects of pipeline type part laser welding of a current dual-way welding clamp are poor, and a welding part product cannot meet process and welding quality needs can be solved. According to the following scheme, the clamp comprises a frame and a mounting plate, positioning columns and supporting blocks are fixedly mounted on the upper surface of the mounting plate, and are evenly distributed, welding part bodies are placedon the positioning columns and the supporting blocks, first mounting bases and second mounting bases are fixedly mounted on the upper surface of the mounting plate in an evenly-distributed manner, first air cylinders are fixedly mounted on one sides of the two sets of first mounting bases in the horizontal direction, first ejector rods are slidingly mounted in the first air cylinders, and penetrate through the outer walls of one sides of the first mounting bases, and the clamp is novel in structure, easy to operate, rapid to use and suitable for being popularized.

Owner:JILIN UNIV

Line rail frog wear inspection ruler

ActiveCN111928752BFast positioning and fixingEfficient and convenient adjustment processMechanical measuring arrangementsRailway auxillary equipmentRail inspectionEngineering

The invention discloses a line rail frog wear inspection ruler, which relates to the technical field of line rail inspection. The invention includes a ruler plate, a control box, a first adjustment frame and a second adjustment frame, the middle part of the ruler plate is fixedly fitted with a second adjustment frame, and the ruler plates on both sides of the second adjustment frame are symmetrically slidingly fitted with a first adjustment frame A control box is fixedly connected to one end surface of the ruler plate; wherein, a first measuring frame and a second measuring frame are respectively fixedly fitted on the bottom surfaces of the two first adjusting frames, and a first measuring frame is arranged on the second adjusting frame. ruler; the middle part of the rear side of the ruler plate is fixedly engaged with iron bars along the direction in which the ruler plate extends. The present invention uses the first electromagnetic column, the control box, the second electromagnetic column, the iron bar, the permanent magnet column, the first abutting column, the placement groove, the first rotating sleeve, the second rotating sleeve, the rotating column, the second abutting column and quantitative The setting of the hole makes the adjustment process of the device measurement more efficient and convenient, the effect of folding and storage is good, and the positioning of the measuring ruler at one-third of the rail surface is more efficient and accurate.

Owner:SHANDONG LINQU SLEEPER

Metal mold positioning and fixing device

Owner:PASCAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com