Nondestructive testing device for pressure vessel of nuclear power unit

A pressure vessel, non-destructive testing technology, applied in the mechanical field, can solve the problems of high radiation risk factor, frequent installation, long time period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

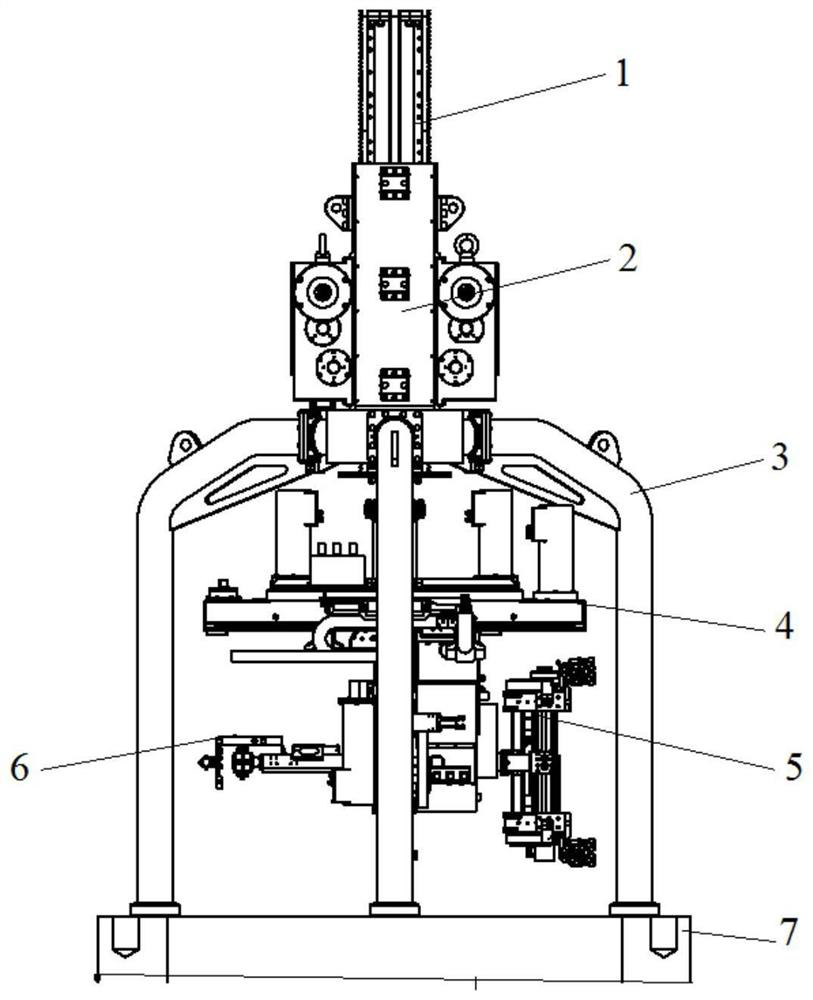

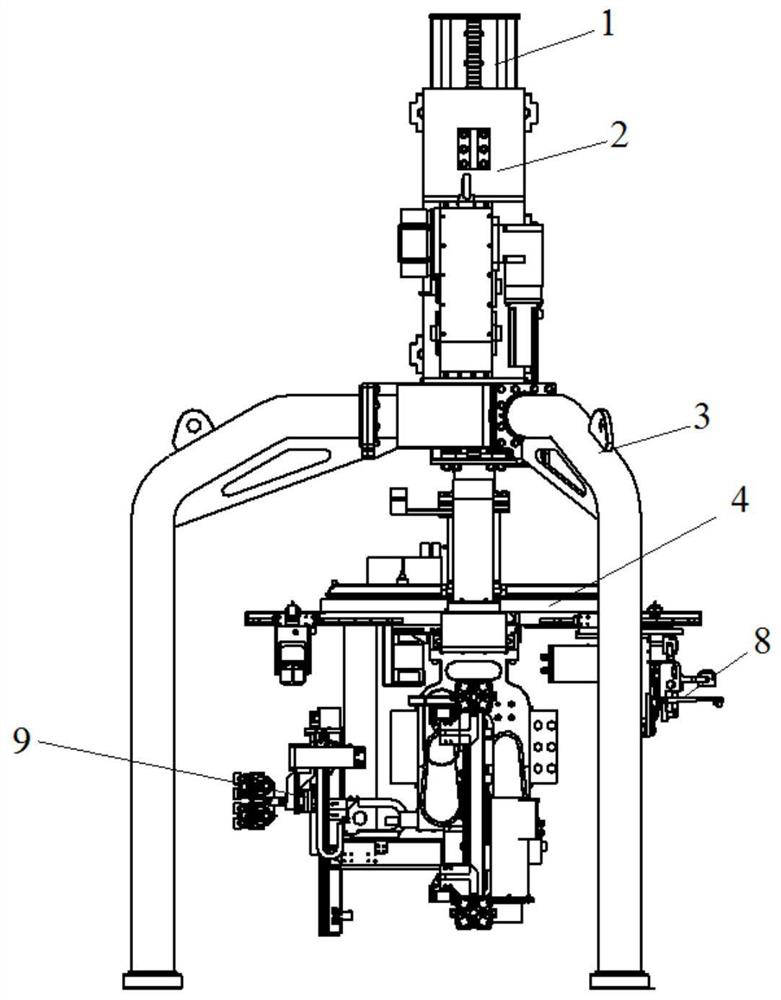

[0026] Such as figure 1 As shown, the reactor pressure vessel detection device consists of a lifting column 1, a lifting guide mechanism 2, a support frame 3, a rotating platform 4, a tangential inspection tool for the connecting weld of the cylinder body 5, a compound inspection tool 6 for the internal connection of the connecting pipe, and an inner circle of the connecting pipe. Angle inspection tool 8 and pressure vessel shell inspection tool 9 are composed.

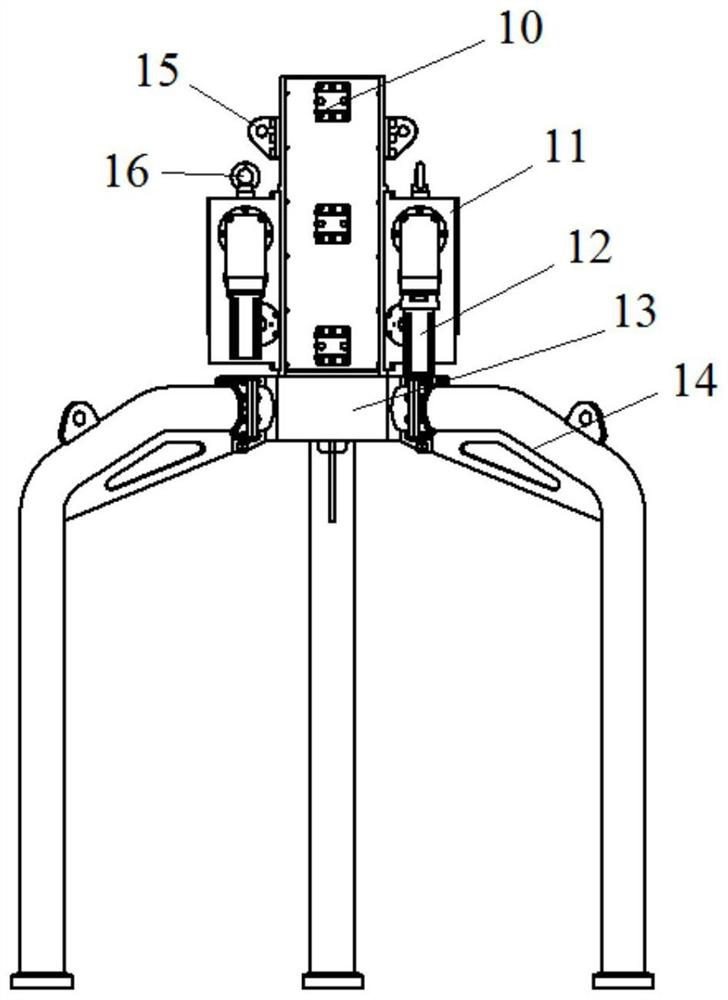

[0027] The lifting column 1 can be spliced by multiple short columns, and a rack is arranged on the column. The supporting frame 3 is composed of a central connecting piece 13 and four or three supporting legs 14, and the three or four supporting legs are connected with the central connecting piece at circumferentially equal angles.

[0028] Such as Figure 5 As shown, the lifting frame 3 inserts the simulated guide column 18 pre-installed on the thread of the pressure vessel flange surface 7 through the support l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com