Spatial wedge type double-clutch

A dual clutch and clutch technology, applied in clutches, one-way clutches, mechanical equipment, etc., can solve the problems of low reliability, high cost, and complicated manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

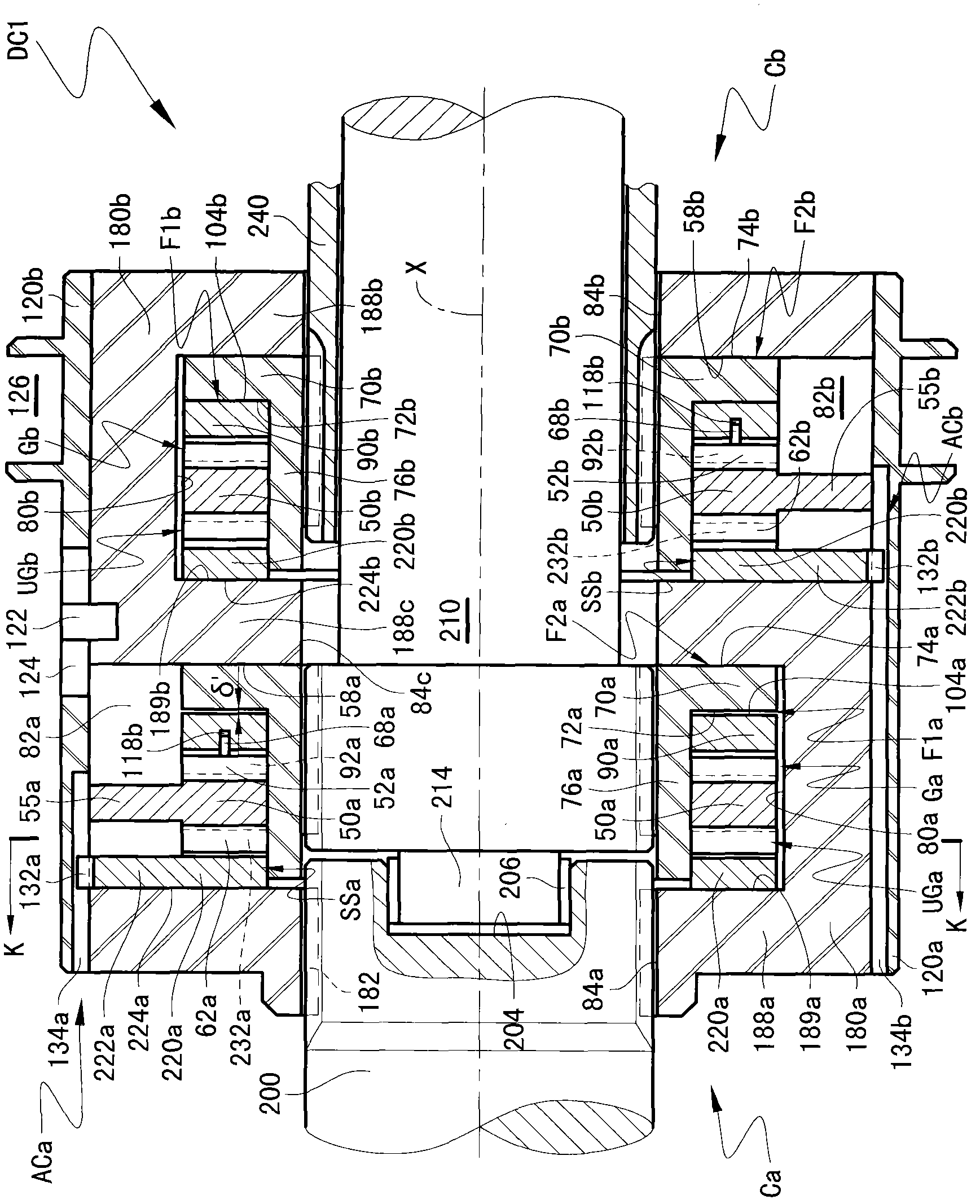

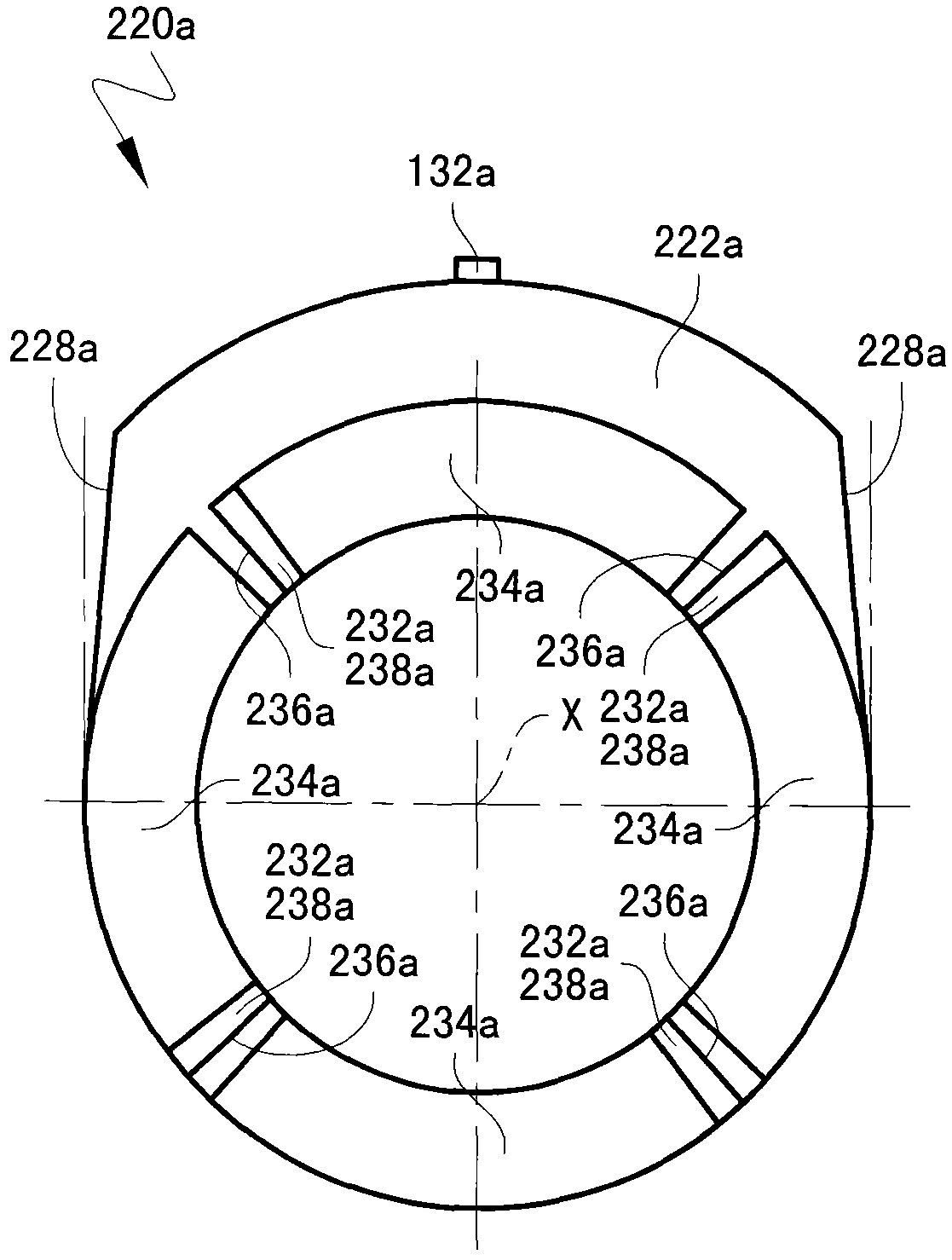

[0057] Embodiment 1: A series-connected space wedging dual-clutch DC1 with a mechanical stepless support mechanism

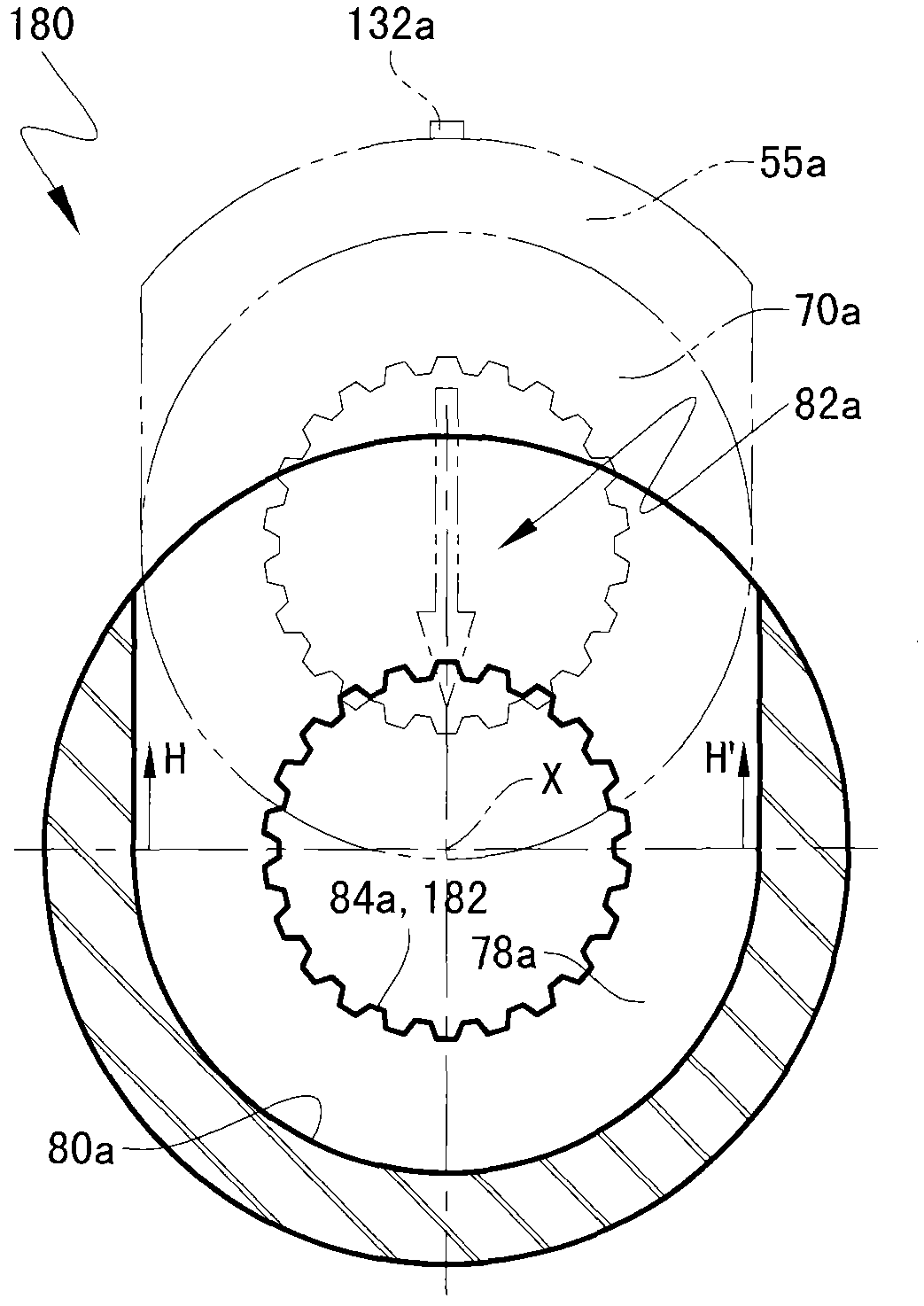

[0058] Figure 1~4 Shown is a shaft-to-shaft double clutch DC1 comprising two sub-clutches Ca and Cb rotating about an axis X and preferably rigidly connected. The two space clutch sub-clutches preferably have an almost identical structure, therefore, the left sub-clutch Ca will be described below as an example.

[0059] The force limiting element 180a formed around the axis X and having the function of sealing the axial force is preferably an annular bag-shaped member, and the axial middle part of the inner peripheral surface 84a, 84c formed around the axis X is coaxially provided with A disc-shaped annular circumferential groove 78a, which is preferably planar. The inner surface of about half of the circumferential groove 78a preferably extends to the outer peripheral surface of the force limiting element 180a along two mutually parallel tangential direction...

Embodiment 2

[0108] Embodiment 2: Tandem space wedging dual clutch DC3 that can be flexibly engaged

[0109] Such as Figure 6 As shown, dual clutch DC3 can be viewed as a hybrid variant of dual clutches DC1 and DC2, and optimally has a setting of λ' at least approximately equal to ξ'. Wherein, the guide 50 is provided with a force arm 55 to be non-rotatably connected with the force limiting element 180 to form a combined bag-shaped guide. Between the supporting end surfaces 51 and 189 of the guide member 50 and the force limiting element 180, there is an elastic element, such as a disc or diaphragm spring 100, so that the dual clutch DC3 has a friction-slip flexible engagement capability. In at least one radial through hole at corresponding positions on the inner surfaces 80 a and 80 b of the circumferential groove 78 , limiting pins 154 a and 154 b are respectively fixedly arranged. The inner radially protruding portions of the limiting pins can respectively axially interfere with the ...

Embodiment 3

[0112] Embodiment 3: Socket type space wedging dual clutch DC4 with mechanical stepless support mechanism

[0113] see Figure 7-11 , the dual clutch DC4 has a relatively small axial dimension relative to DC1. Among them, the two sub-clutches Ca and Cb are arranged in a radially inner and outer sleeve type. For this reason, the package housing that provides the sealing function of axial force is modified into an axial combined member, which includes a substantially annular force limiting element 160a provided with at least one arc-shaped protrusion 166, and a substantially annular force limiting element 160a provided with at least one screw hole. Force limiting element 160b. The screw 176 screwed into the threaded counterbore 183 on both sides of the top of each arc-shaped protrusion 166 fixes the force-limiting elements 160a and 160b into a rigid member, and defines the radial inner side of the arc-shaped protrusion 166. and two flat disc-shaped circumferential grooves on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Axial width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com