Device for cold cutting of pouring gate of molded outside plastic product

A gate and cold cutting technology, applied in the field of gate cold cutting equipment for plastic products, can solve the problems of difficult quality, rising labor costs, shortage of operators, etc. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations are now described in detail.

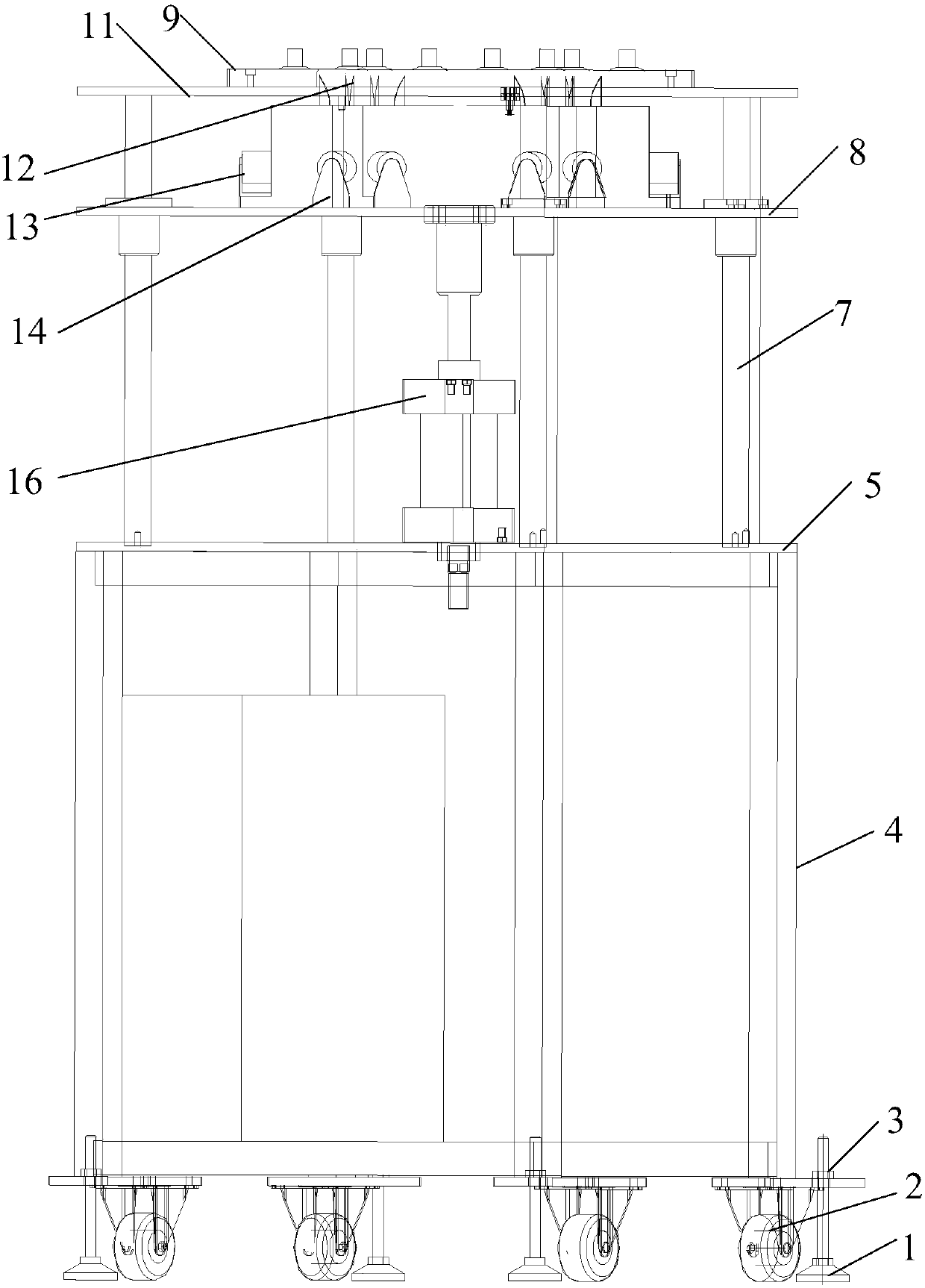

[0016] Such as figure 1 As shown in the figure, the equipment used for cold-cutting the gate of plastic products outside the mold is equipped with a lower fixing plate 5 on the fixing bracket 4, and a guide column 7 is distributed on the lower fixing plate 5, and the support plate 8 is placed on the guide column through its guide hole. 7, a guide bushing is provided in the guide hole of the support plate 8, an upper fixed plate 11 is installed on the top of the guide column 7, a jig plate 9 is arranged on the upper fixed plate 11, and a support frame 14 is installed on the support plate 8 to support The scissors 12 are installed on the frame 14, and the driving unit 13 is connected with the scissors 12. The driving unit 13 is a cylinder, and the lifting cylinder 16 is installed on the lower fixed plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com