a hoisting tool

A tooling and hoisting technology, which is applied in hoisting devices, portable lifting devices, etc., can solve the problems of cost increase, production operation overlap, and low efficiency, and achieve the effects of simple structure, convenient operation, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment proposes a hoisting tool applied to an automobile assembly workshop for transfer and auxiliary assembly of components at different stations.

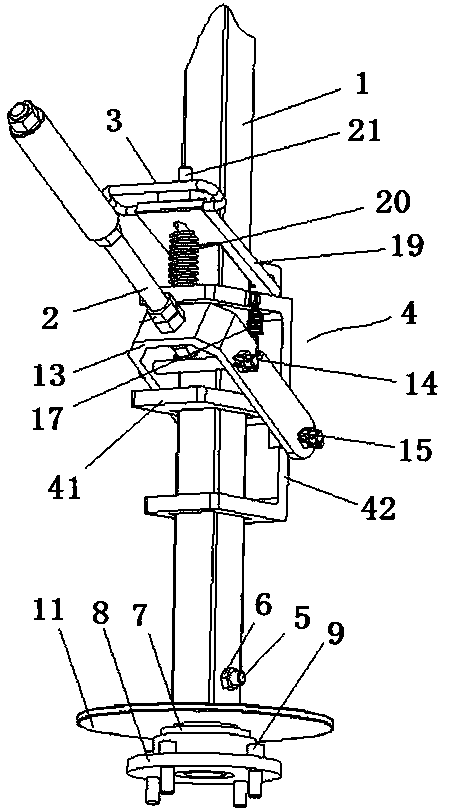

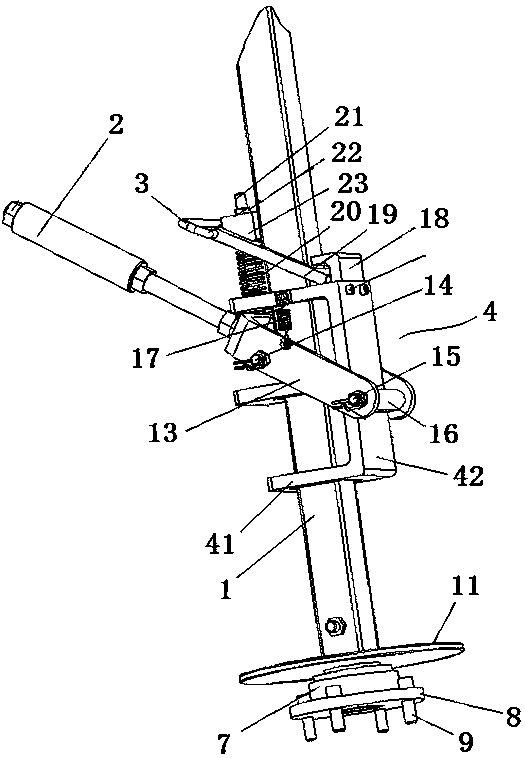

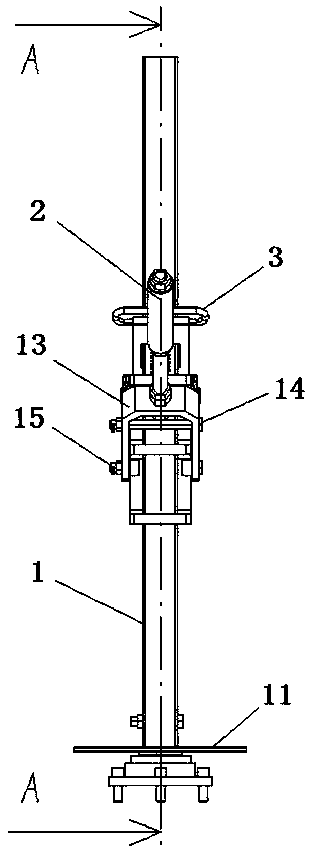

[0027] like Figure 1~5 As shown, the hoisting tooling of this embodiment includes a main pole 1, a lifting handle 2, a lowering handle 3 and a moving frame 4, wherein:

[0028] The main strut 1 has a rectangular cross-section, which is formed by socketing the upper hollow rod and the lower solid rod, and is fixedly connected by bolts 5 and nuts 6 at the junction of the hollow rod and the solid rod; the main strut 1 The surface is provided with anti-skid lines (not shown in the figure), the bottom of the main pole 1 is rotatably mounted on the bearing seat 8 through the bearing 7, and the bearing seat is fixed on the running trolley 10 by a number of uniformly distributed hexagon socket head bolts 9. The main pole 1 is fixedly provided with a fixed plate 11 above the bearing, and the fixed plate 11 is attached to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com