Intelligent sensor prototype testing device

A technology for intelligent sensor and prototype testing, which is applied in the direction of measuring devices, instruments, calibration/testing of force/torque/power measuring instruments, etc., and can solve problems such as difficulty in stabilizing the horizontal direction of the device, difficulty in determining the tension sensor, and large errors. Achieving a high degree of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

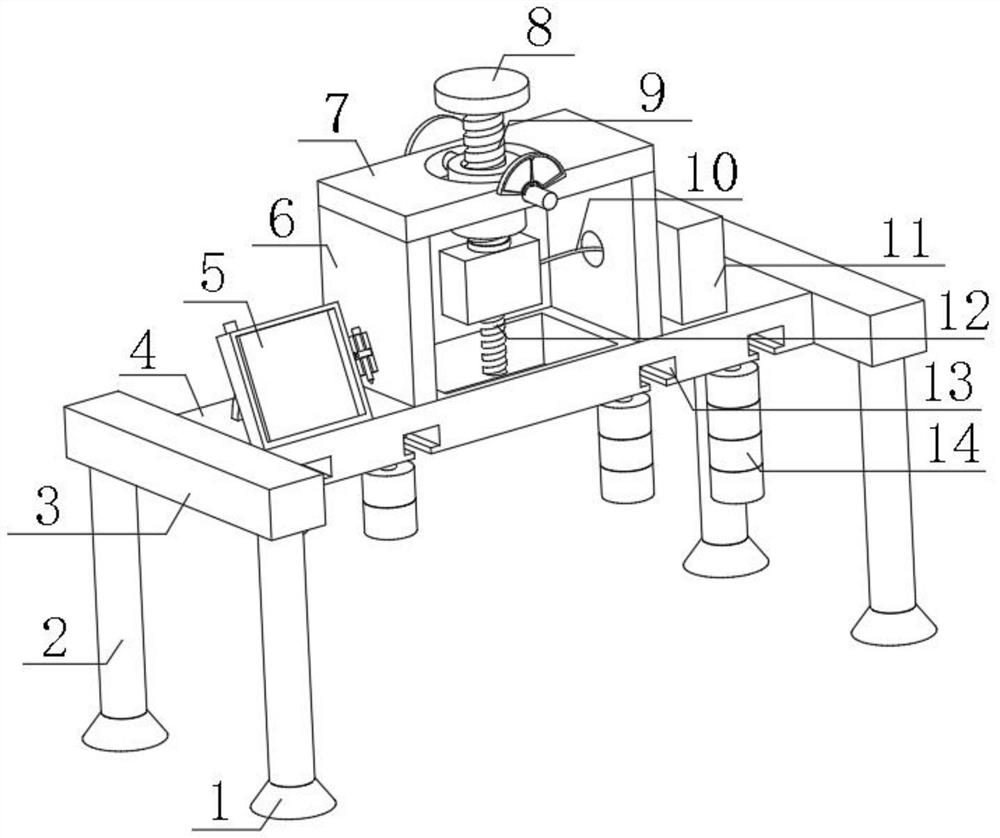

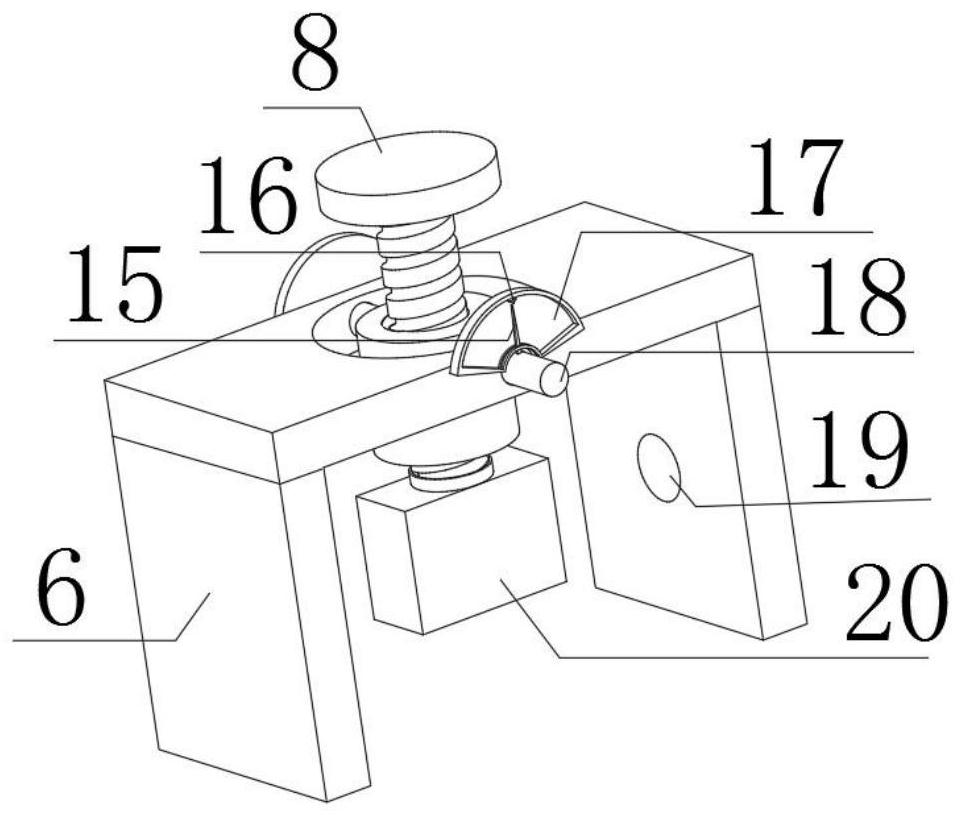

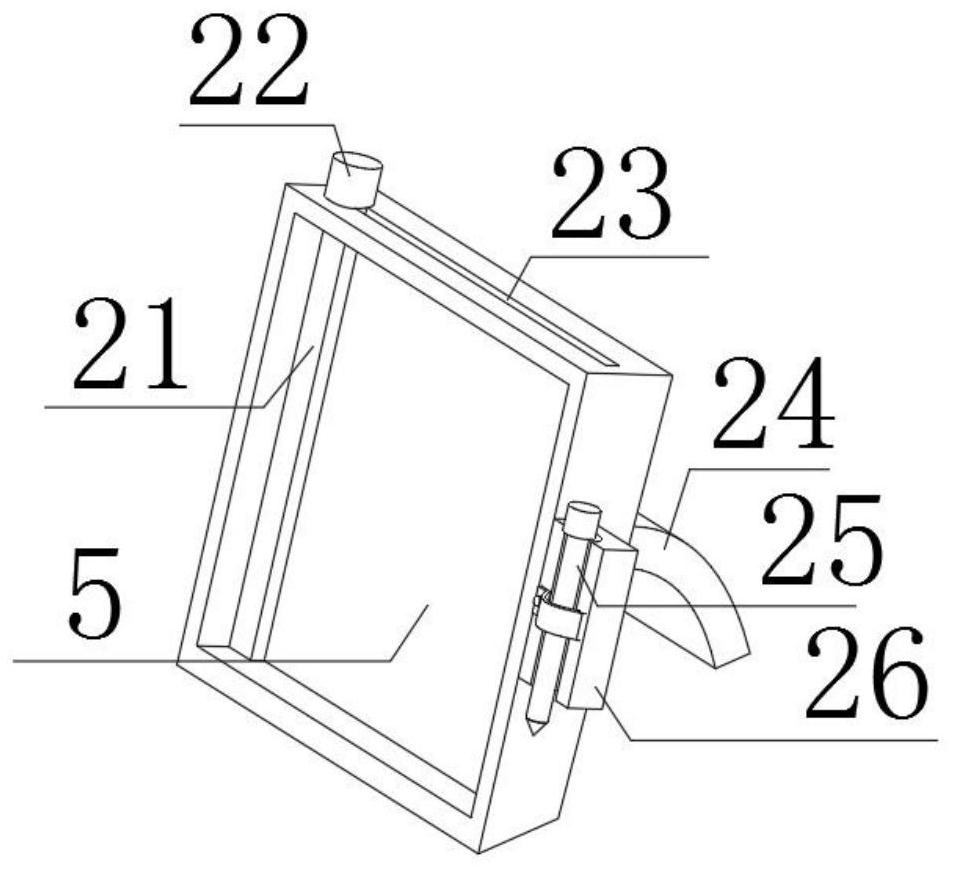

[0027] refer to Figure 1-4 , a smart sensor prototype test device, comprising a bottom plate 4, the central position of the top outer wall of the bottom plate 4 is fixedly connected with two support plates 6 by bolts, and the same horizontal plate 7 is fixedly connected on the top outer walls of the two support plates 6, and the horizontal plate 7 The central position of the outer wall of the top of the plate 7 is provided with a mounting hole, and the outer walls of both sides of the horizontal plate 7 are inserted with rotating rods 18, and the opposite ends of the two rotating rods 18 are fixedly connected with the same threaded sleeve, and the inner wall of the threaded sleeve is threaded. Connected with a first threaded rod 9, the top of the first threaded rod 9 is fixedly connected with a knob 8, the outer walls of both sides of the horizontal plate 7 are fixedly connected with finger plates 17, and the inner walls of one side of the two finger plates 17 are provided wit...

Embodiment 2

[0036] refer to Figure 5, a smart sensor prototype test device, comprising a bottom plate 4, the central position of the top outer wall of the bottom plate 4 is fixedly connected with two support plates 6 by bolts, and the same horizontal plate 7 is fixedly connected on the top outer walls of the two support plates 6, and the horizontal plate 7 The central position of the outer wall of the top of the plate 7 is provided with a mounting hole, and the outer walls of both sides of the horizontal plate 7 are inserted with rotating rods 18, and the opposite ends of the two rotating rods 18 are fixedly connected with the same threaded sleeve, and the inner wall of the threaded sleeve is threaded. Connected with a first threaded rod 9, the top of the first threaded rod 9 is fixedly connected with a knob 8, the outer walls of both sides of the horizontal plate 7 are fixedly connected with finger plates 17, and the inner walls of one side of the two finger plates 17 are provided with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap