An improved motor

An improved, air-frame technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of environmental pollution of fans, influence of motor operation, and inability to be disassembled separately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as predetermined and covered by the claims.

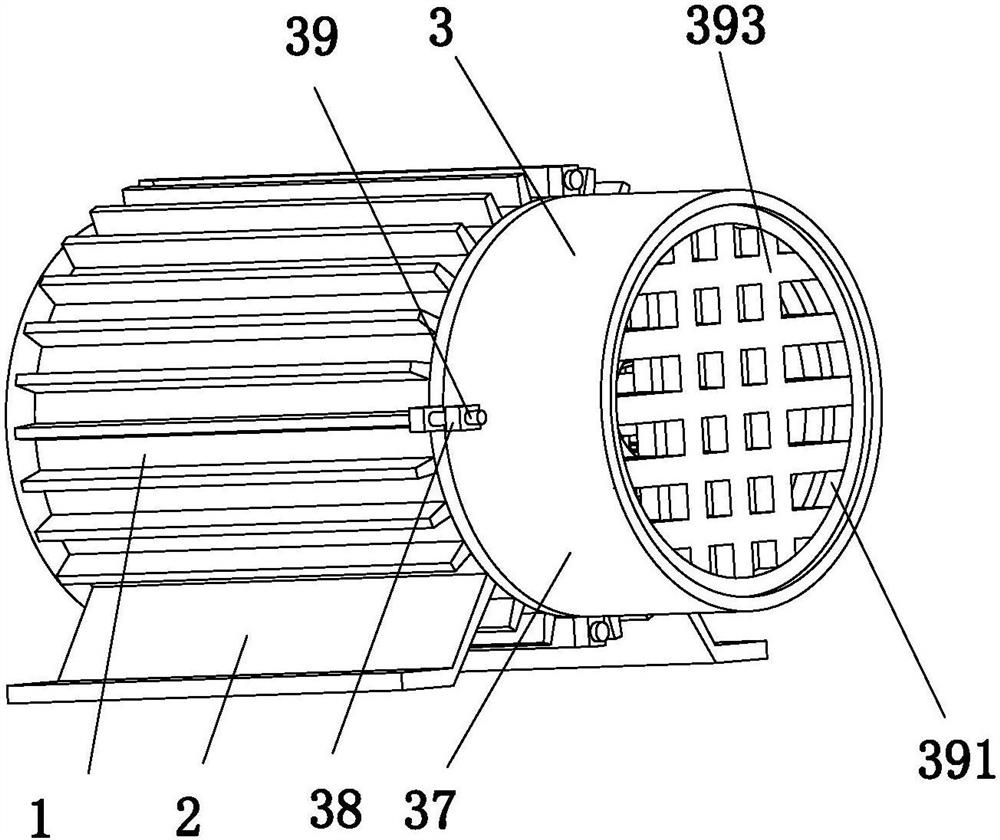

[0031] like Figure 1 to Figure 10 As shown, an improved motor includes a fuselage 1, a base 2 and a front mechanism 3. The lower end of the fuselage 1 is installed with a base 2, and the lower end of the base 2 is installed on the existing working ground. The front end of 1 is provided with a front-end mechanism 3 .

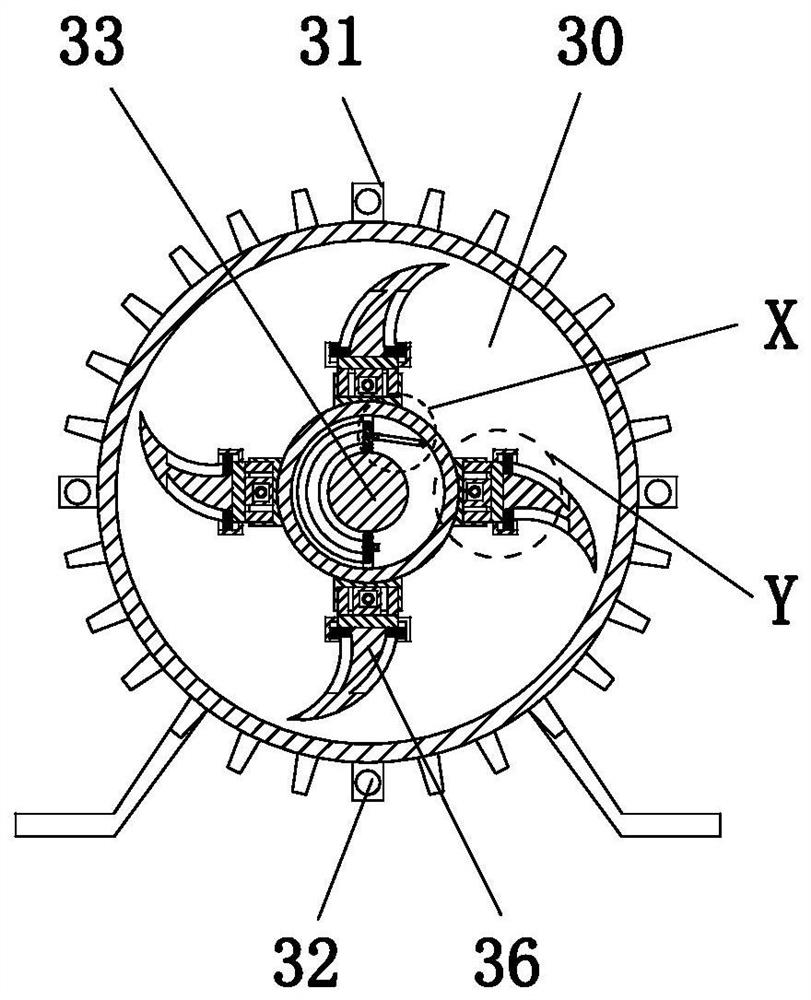

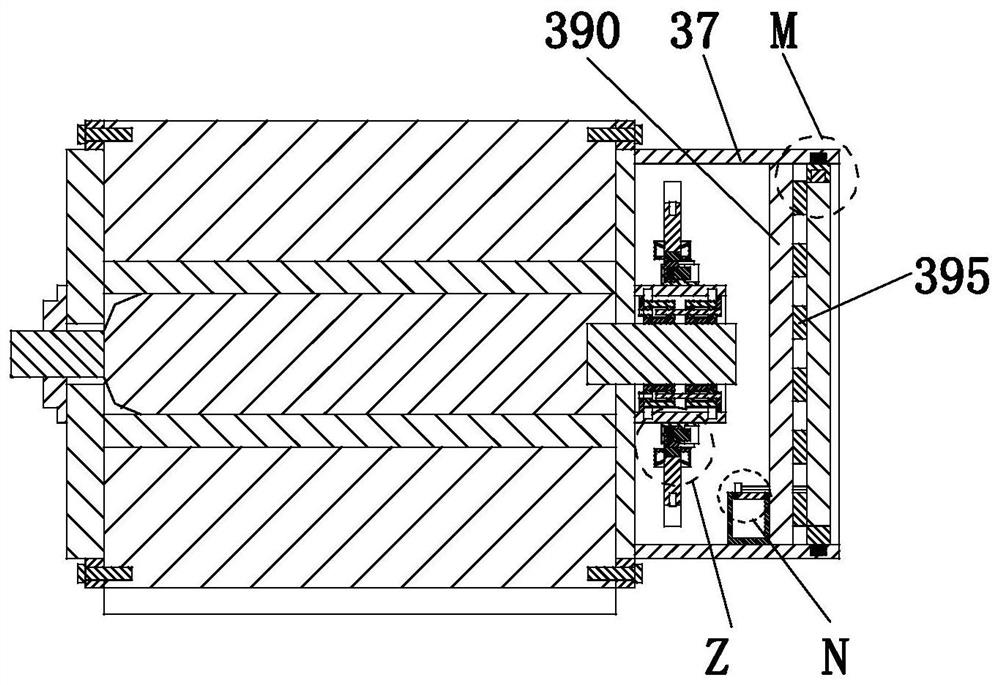

[0032] The front-end mechanism 3 includes a front end cover 30, a convex plate 31, a connecting bolt 32, a connecting shaft 33, a ring 34, a connecting group, a fan blade 36, a hood 37, an ear plate 38, a fastening bolt 39 and a grid. Plate 390, a convex plate 31 is installed on the outer ring surface of the front end cover 30, the convex plates 31 are evenly arranged along the circumferential direction of the front end cover 30, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com