Sliding compression type asynchronous motor

A kind of technology of asynchronous motor and compression type, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of increasing motor load, inflexible and changeable use, and increasing the difficulty of mold processing, etc., and achieves the effect of wide installation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

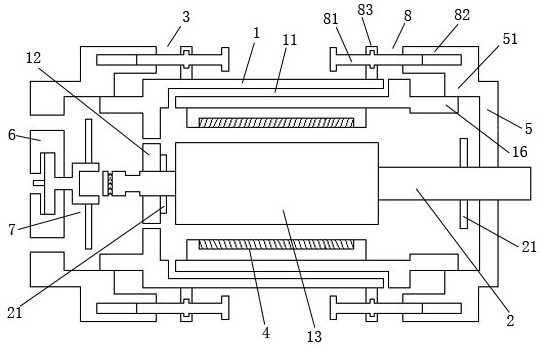

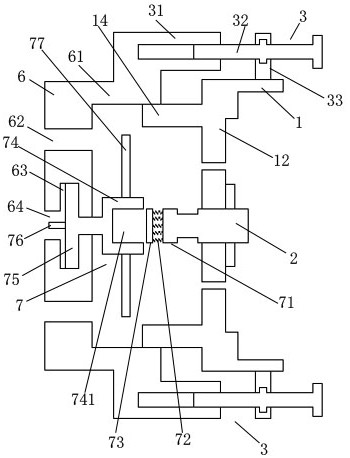

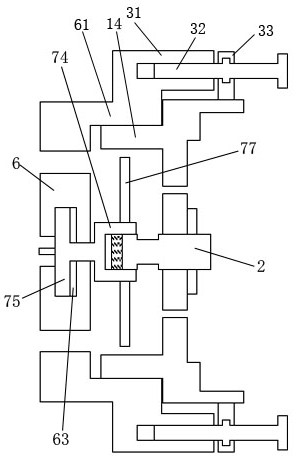

[0020] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] Such as Figures 1 to 5 As shown, a sliding compression asynchronous motor includes an outer shell 1, a front end cover 5, a rear end cover 6, a rotating shaft 2, a stator 4, a plug-in linkage mechanism 7, a rear end cover driving mechanism 3, and a front end cover driving mechanism 8. The inner end of the front end cover 5 is provided with a front end socket ring body 51; the outer front end of the outer shell 1 is provided with a front end inner core ring body 16; the front end cover 5 is connected through the front end socket around the inner end The ring body 51 is slidably socketed on the front end inner core ring body 16 around the front end of the outer shell 1; the front end cover drive mechanism 8 includes a front end threaded cylinder 82, a front end drive screw rod 81, and a front end positioning block 83; the front end cover ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap