Gripper and mechanical arm for assembling large-tonnage prefabricated structural block

A prefabricated structure and large-tonnage technology, applied in the direction of manipulators, claw arms, shaft equipment, etc., can solve the problems that the ground cannot guarantee flatness, affect the operation efficiency, and the operation range is limited, and achieve good stability and operability. The effect of safe and efficient process, reducing strength and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

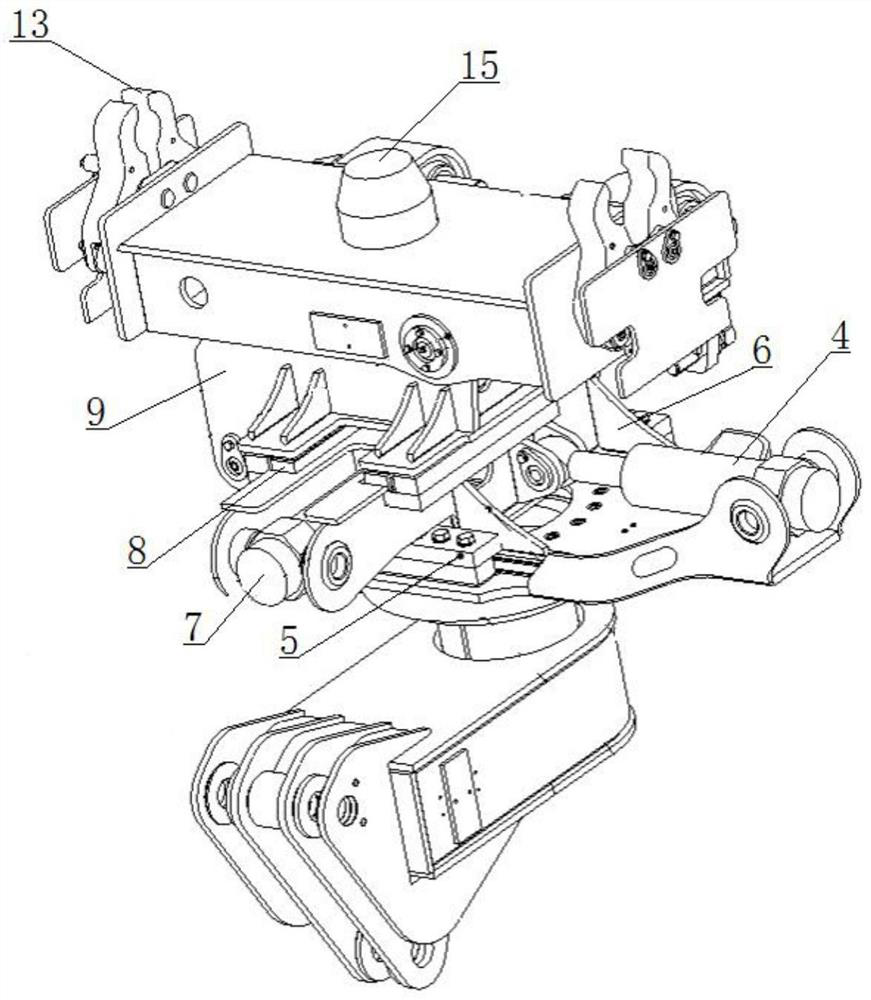

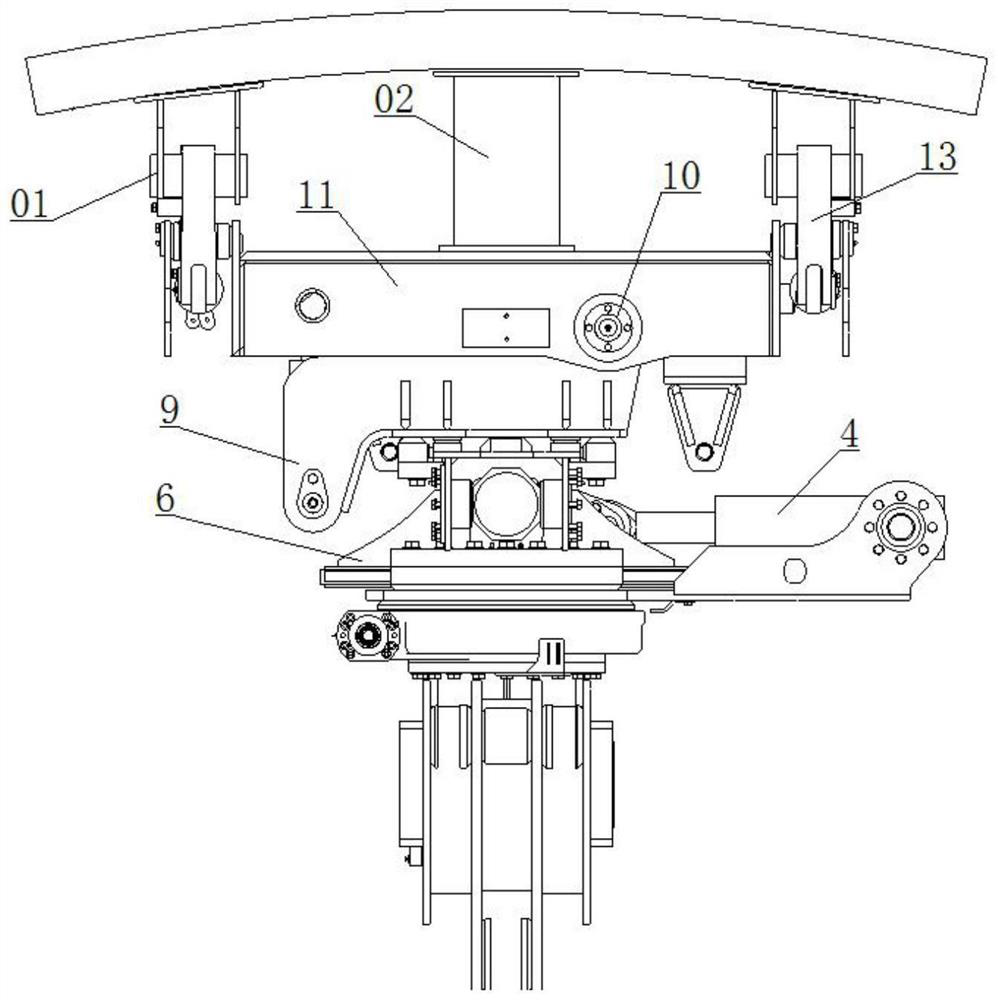

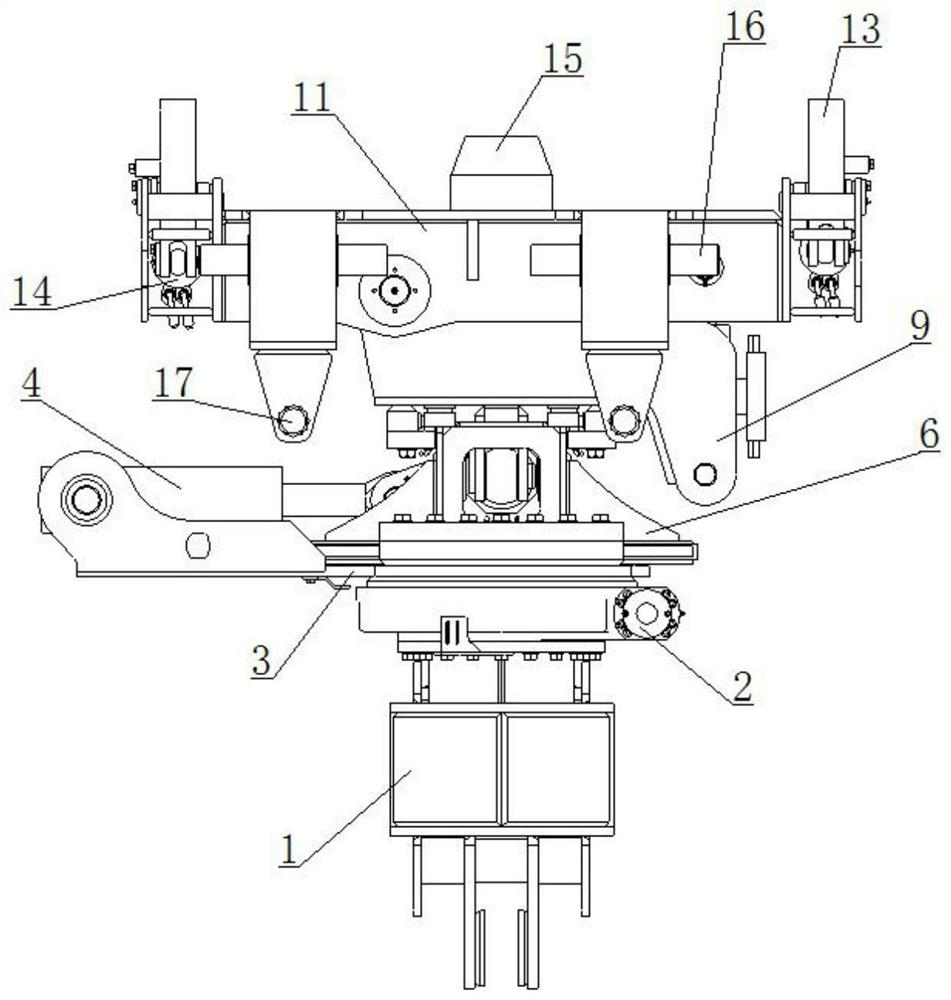

[0034] see Figure 1-Figure 8 , a gripper for assembling large-tonnage prefabricated structural blocks, the gripper is used in conjunction with the tooling pre-installed on the prefabricated structural block, and the tooling includes the first top mold tooling 01 installed on the top prefabricated structural block , the second top mold tooling 02 and the side mold tooling 03 installed on the side wall prefabricated structural block, the first top mold tooling 01 is provided with a clamping position 01.1, and the second top mold tooling 02 is cylindrical Structure and one end away from the top prefabricated structural block is open, and the side mold tooling 03 is provided with a U-shaped groove 03.1 with the opening facing downward, and the number of U-shaped grooves 03.1 can be designed according to the actual situation.

[0035] The gripper includes a support base 1, a rotary mechanism, a first translation mechanism, a second translation mechanism and a clamping mechanism. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com