Assembling trolley for assembling large-tonnage prefabricated structural block

A prefabricated structure and large-tonnage technology, applied in shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of unsatisfactory flatness of the ground, poor flexibility, and affecting operation efficiency, etc., and achieve good stability and operability, satisfying Accurate positioning requirements, safe and efficient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

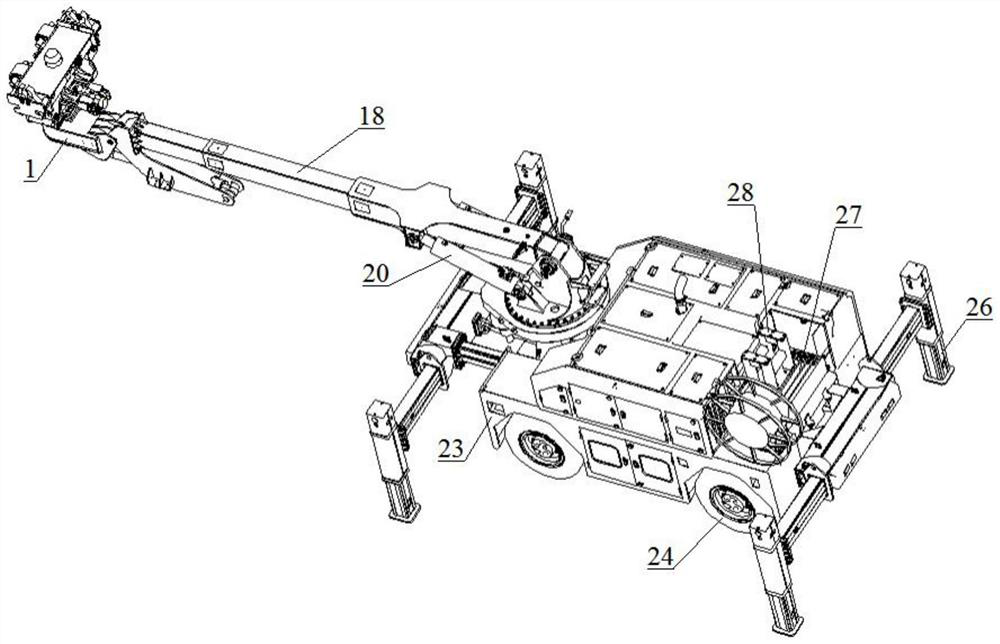

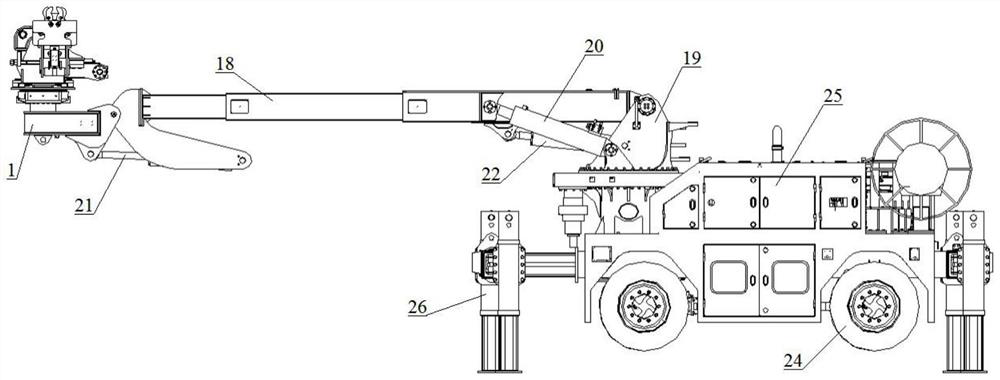

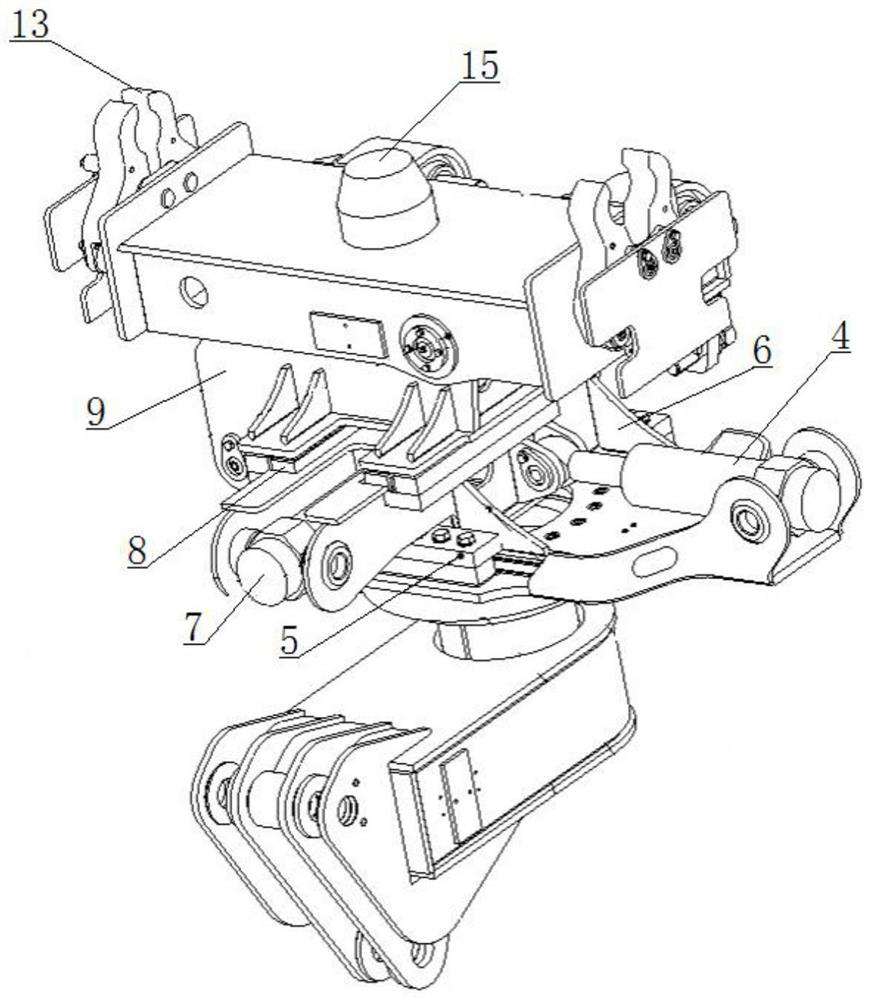

[0037] see Figure 1-Figure 10 , an assembly trolley for assembling large-tonnage prefabricated structural blocks, including a trolley main body and a mechanical arm.

[0038]The trolley main body includes a trolley chassis 23 and a walking system 24 , a power control system 25 and a pressure-bearing leg 26 arranged on the trolley chassis 23 . The walking system 24 adopts a wheeled structure, which can facilitate the rapid two-way movement of the trolley; the power control system 25 is used to provide power for the walking and work of the trolley, and to control the use of the entire trolley; in this embodiment, The number of the pressure-bearing legs 26 is four and divided into two groups, which are symmetrically arranged at the front and rear ends of the chassis 23 of the trolley. The inside of the pressure-bearing legs 26 is equipped with a hydraulic cylinder for realizing the pressure-bearing legs. In the vertical expansion and contraction, the pressure-bearing legs 26 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com