Indoor and outdoor ultra-thin type electric energy-saving heating assembly

An ultra-thin, indoor and outdoor technology, applied in electric heating systems, space heating and ventilation details, household heating, etc., can solve the problem of reducing the effective height of the indoor space, the stability of the floor decoration cannot be guaranteed, and the flatness is not good, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

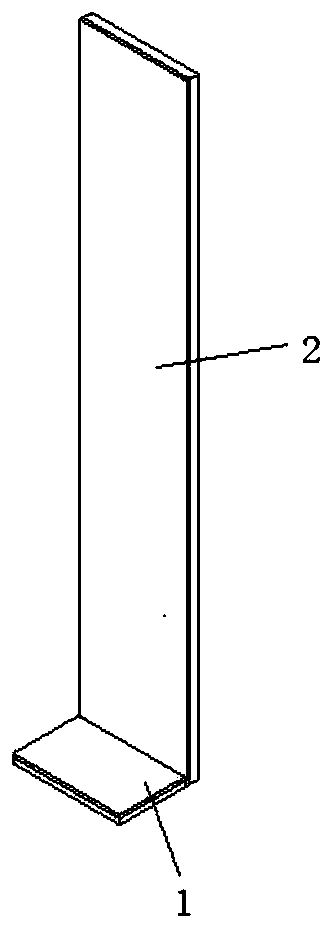

[0093] like figure 1 As shown, the indoor and outdoor ultra-thin electric energy-saving heating components include a floor heating unit 1 and a wall heating unit 2 .

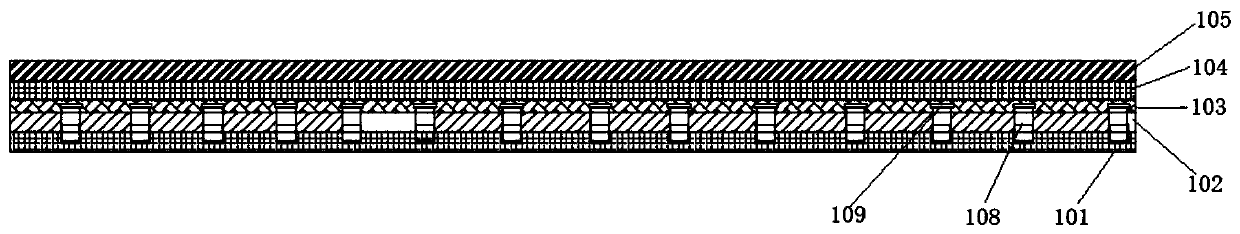

[0094] like figure 2 As shown, the floor heating unit 1 includes a ground base leveling layer 101 , a ground insulation layer 102 , a ground wire mesh layer 103 , a ground cement bonding leveling layer 104 , and a ground decorative panel layer 105 that are sequentially attached from bottom to top.

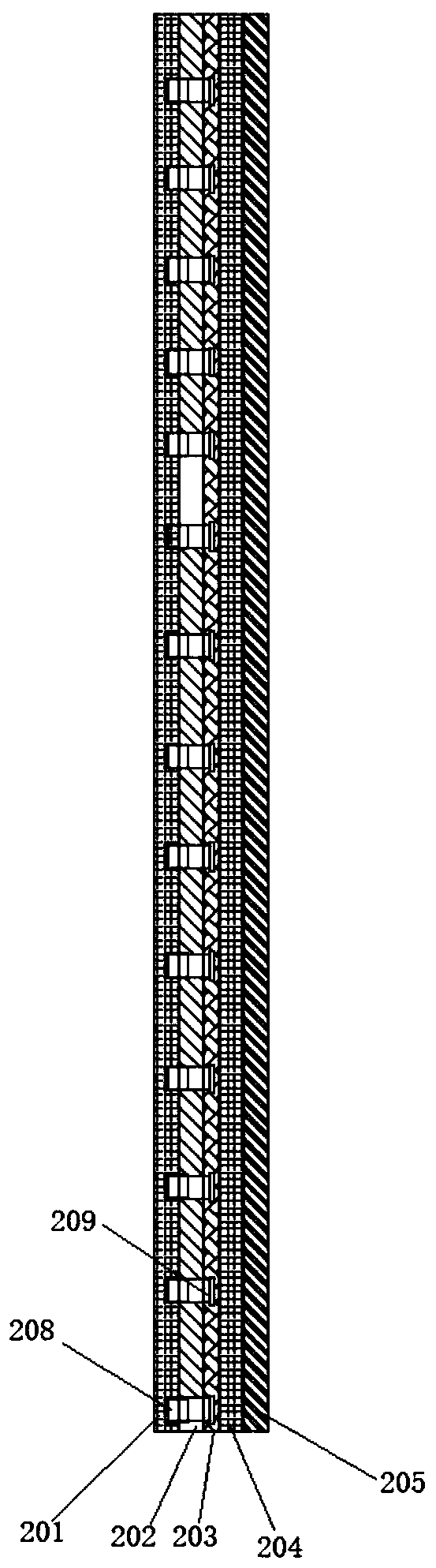

[0095] like image 3 As shown, the wall heating unit 2 includes a wall base leveling layer 201 , a wall insulation layer 202 , a wall wire mesh layer 203 , a wall cement bonding leveling layer 204 , and a wall decoration panel layer 205 that are arranged sequentially.

[0096] Wherein, the thickness of the ground insulation layer 102 and the thickness of the wall insulation layer 202 are both less than 1 cm.

[0097] In this embodiment, there is no special requirement for the material of the ground base leveling ...

Embodiment 2

[0140] The indoor and outdoor ultra-thin electric energy-saving heating assembly in Embodiment 1 further includes a thermostat group, and the thermostat group respectively controls the first electric heating wire layer and the second electric heating wire layer. The temperature controller group is used to control the working state of the first electric heating wire layer and the second electric heating layer.

[0141] The thermostat group in this embodiment includes four thermostats, namely thermostat A5, thermostat B6, thermostat C7, thermostat D8; thermostat A5, thermostat B6, thermostat Both the controller C7 and the temperature controller D8 are fixed on the side wall of the wall decoration panel layer 205 facing away from the wall cement bonding leveling layer 204 .

[0142] The temperature controller A5 and the temperature controller B6 are used to control the working state of the first electric heating wire layer, and the temperature controller C7 and the temperature co...

Embodiment 3

[0149] The indoor and outdoor ultra-thin electric energy-saving heating assembly in Embodiment 1 further includes a thermostat group, and the thermostat group respectively controls the first electric heating wire layer and the second electric heating wire layer. The temperature controller group is used to control the working state of the first electric heating wire layer and the second electric heating layer.

[0150] The temperature controller group in this embodiment includes two temperature controllers, namely the temperature controller E9 and the temperature controller F10.

[0151] The U-shaped electric heating wire C230 laid in each U-shaped wiring groove C214 in the wall heating unit 2 is sequentially connected in series through the arc-shaped electric heating wire C238 to form a first-level electric heating wire layer, and each U-shaped electric heating wire in the wall heating unit 2 The U-shaped electric heating wire E232 laid in the wiring groove E218 is connected i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com