Manual positioning construction method of permanent steel column

A steel column and artificial technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of wasting manpower and material resources, difficulty in guaranteeing construction quality, increasing construction period, etc., achieving significant economic benefits, easy construction quality, and improved construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

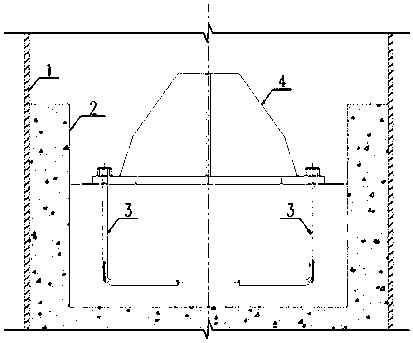

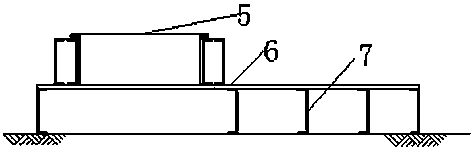

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments:

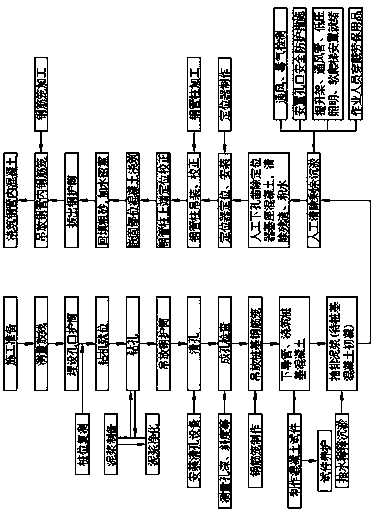

[0040] like figure 1 As shown, a construction method for manual positioning of permanent steel columns includes the following steps:

[0041] 1. Construction preparation

[0042] The construction site shall be leveled and solid, and the rotary drilling rig shall be placed with a steel plate to prevent the drilling rig from tilting during the drilling process, which may cause the verticality of the hole to be unsatisfactory;

[0043] 2. Measure and pay off

[0044] Use the total station to measure the position of the pile center, drive the wooden pile to the fixed point, and lead it around by the "cross method" to make the pile guard point.

[0045] 3. Buried orifice protector

[0046] According to the design of the center line of the pile position, the hole protection tube is embedded, and the deviation between the center of the protection tube and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com