Explosive Welding Method of Ring Composite Structure

A technology of explosive welding and composite structure, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of waste of metal materials and processing processes, achieve the effect of improving the quality of explosive welding, reducing waste, and overcoming limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

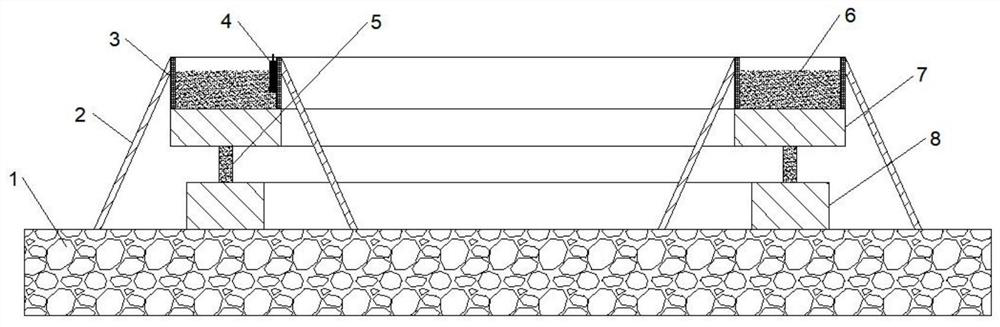

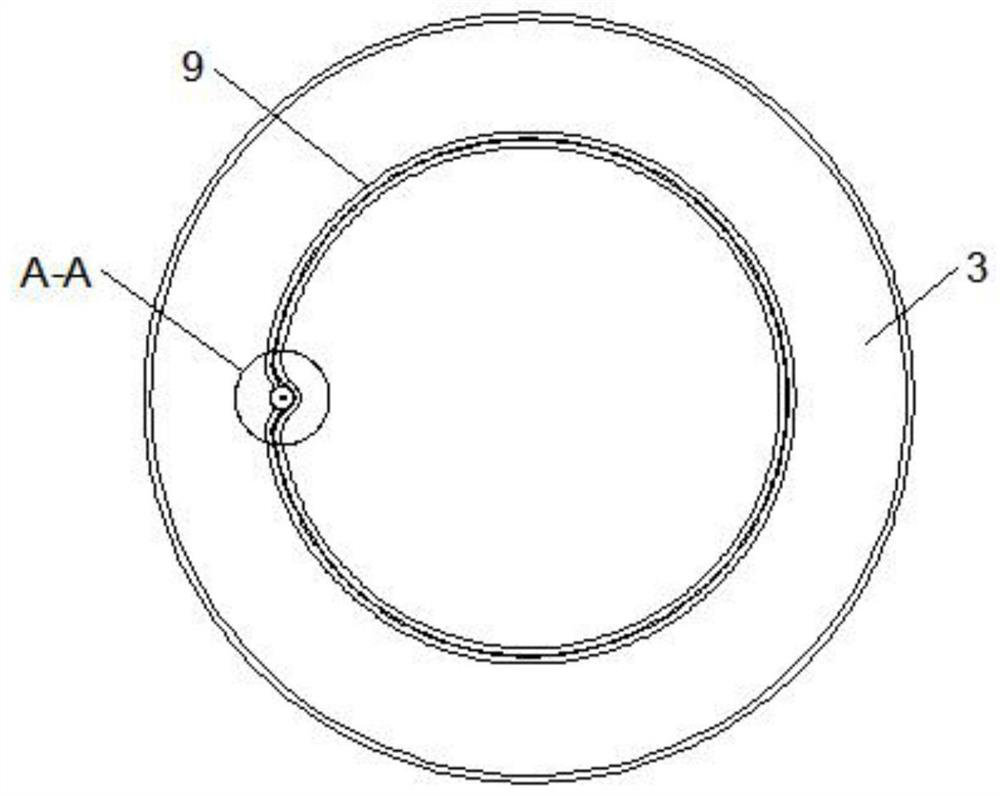

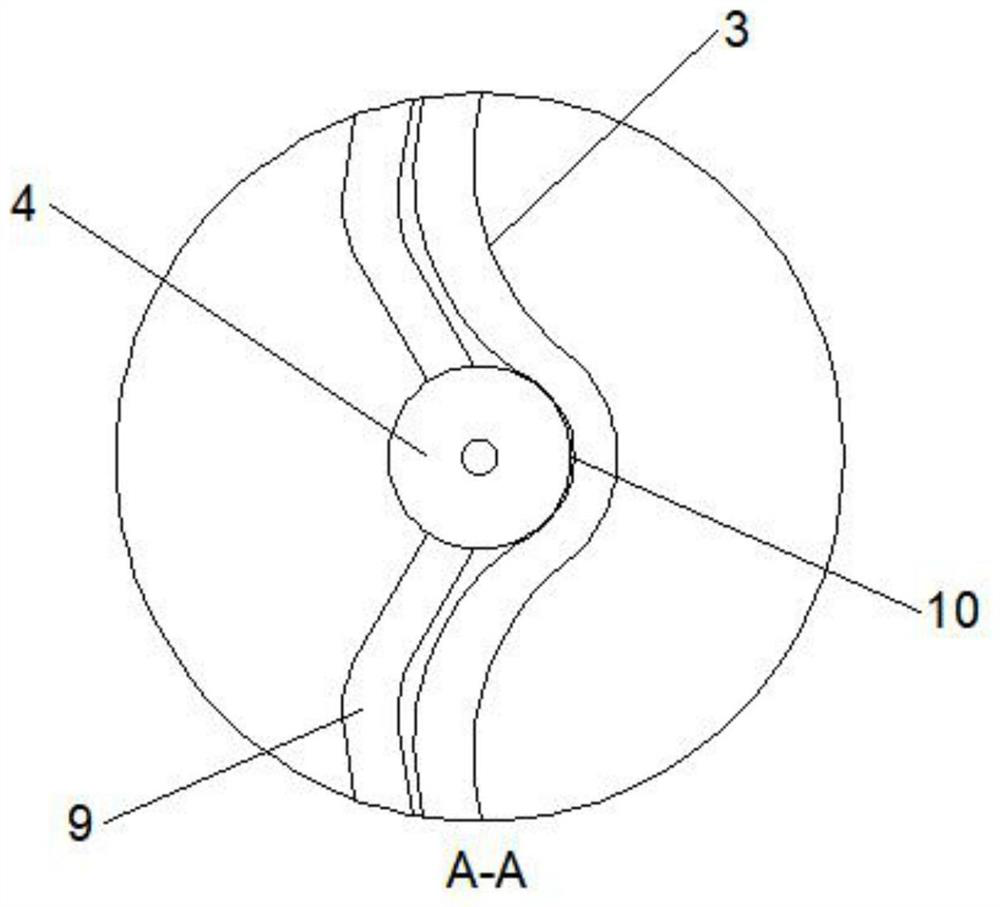

[0034] A kind of annular composite structure explosive welding process method proposed by the present invention, the specific implementation operation steps are as follows:

[0035] S1: substrate treatment

[0036] Choose Q345R (40*Φ790 / Φ640) as the substrate, and use a grinding wheel for grinding and polishing, so that the joint surface is completely exposed to metallic luster, the surface is smooth and smooth, and the roughness is less than 6.3μm;

[0037] S2: Composite material processing

[0038] Choose TA2 (3*Φ830 / Φ600) as the composite material, use a thousand impeller or grinding wheel to polish the joint surface as a whole, remove the oxide layer on the joint surface, completely reveal the metallic luster, the unevenness of the composite board surface <3mm / m, the roughness < 3.2μm;

[0039] S3: pairing

[0040] Pair the composite material with the base material to operate the explosion operation point; place the base material horizontally on the fort (foundation), p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com