Wooden furniture surface polishing device

A technology for surface polishing and wooden furniture, which is applied in the direction of surface polishing machine tools, manufacturing tools, grinding drives, etc., can solve the problems of reducing work efficiency, time-consuming and laborious work, and low work efficiency, so as to improve stability and prevent damage , the effect of weakening the longitudinal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

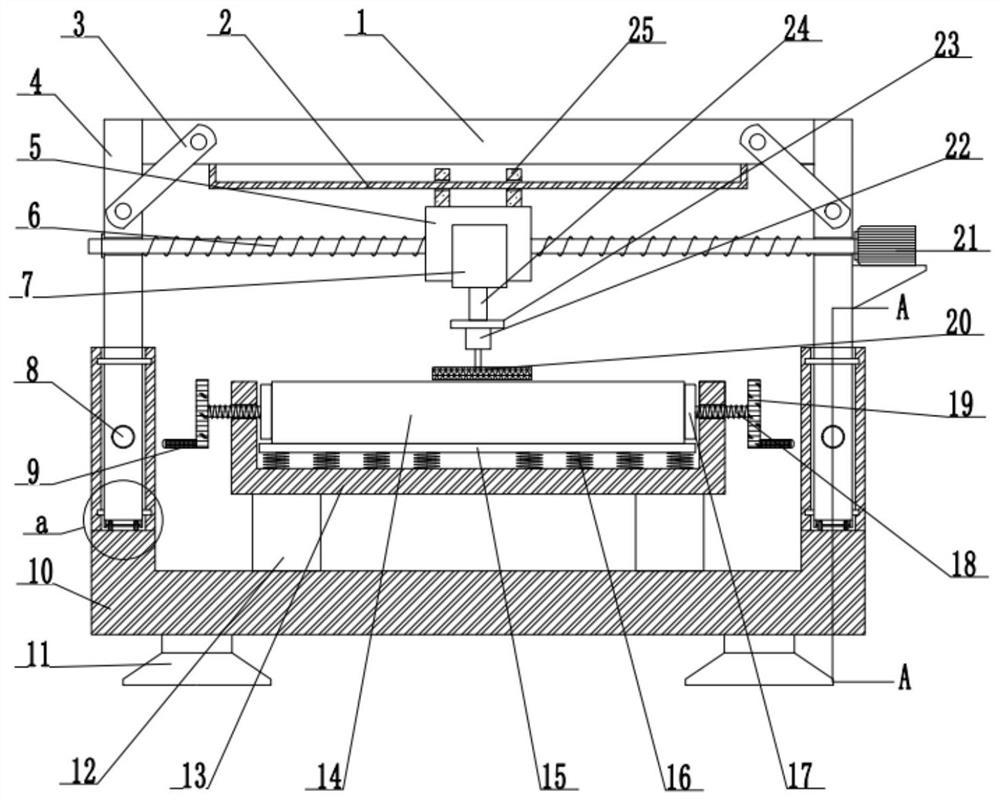

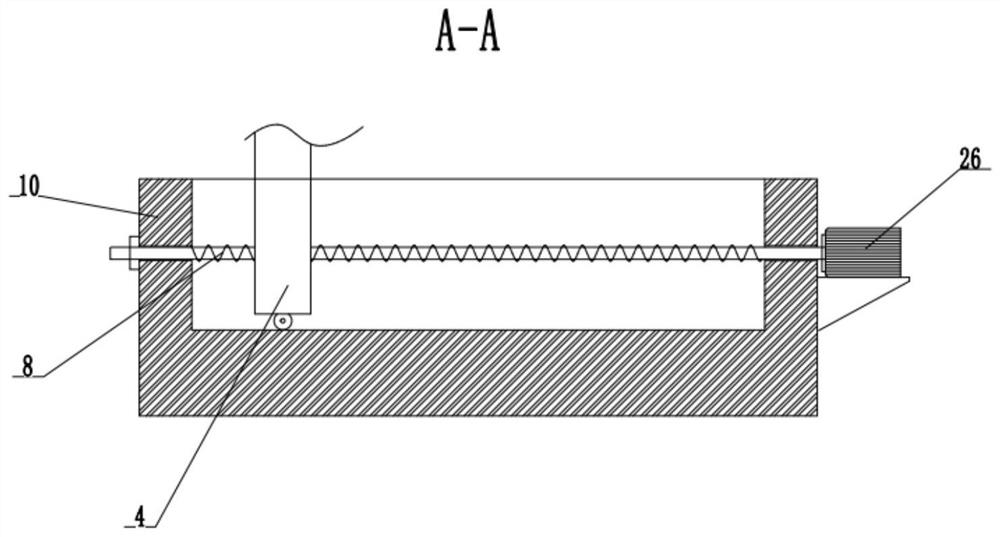

[0027] see Figure 1 to Figure 4 , a wooden furniture surface polishing device, comprising a beam 1, a base 10, a workbench 13, a polishing wheel 20 and an asynchronous motor 22, the workbench 13 is connected to the base 10 through a bracket 12, and the groove provided on the surface is embedded There is a furniture plate 14, the polishing wheel 20 is connected to the asynchronous motor 22 fixed on the bottom of the fixed plate 23 through the drive shaft, and the asynchronous motor 22 drives the polishing wheel 20 to rotate through the drive shaft, thereby realizing the function of polishing, and the fixed plate 23 passes through The hydraulic strut 24 is connected to the hydraulic cylinder 7 embedded in the side wall of the slider 25, and the hydraulic cylinder 7 drives the buffing wheel 20 to move up and down through the hydraulic strut 24, which is convenient for adjusting the height of the buffing wheel 20, and can better control the furniture plate 14 Excellent polishing ...

Embodiment 2

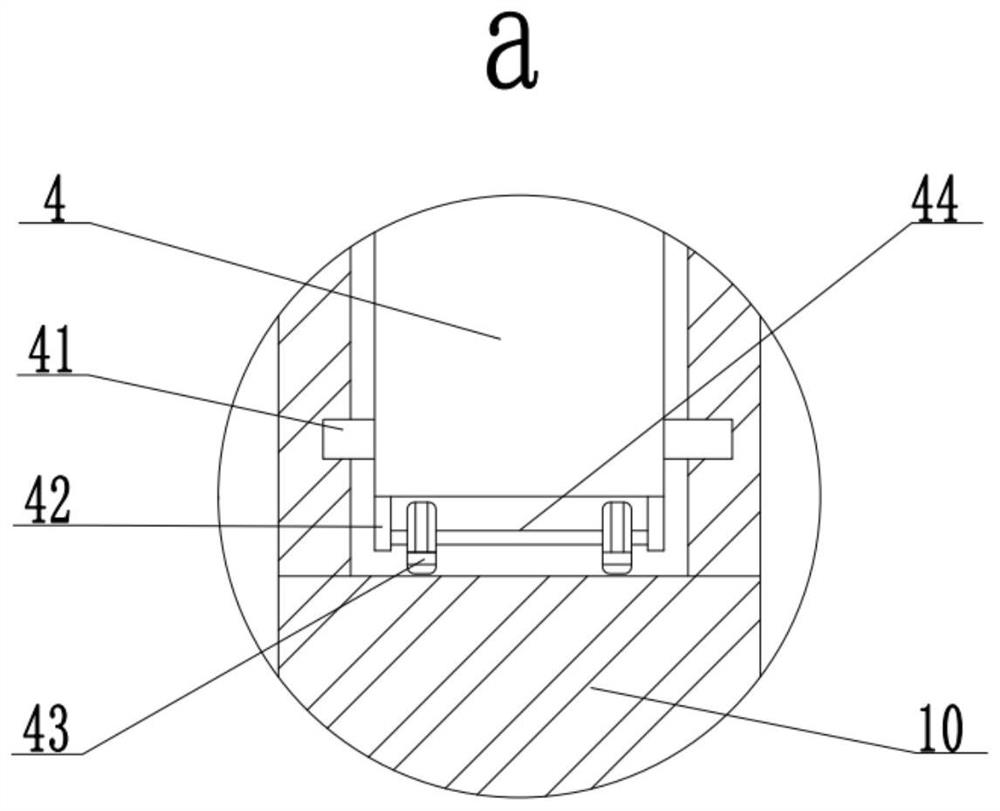

[0034] see figure 1 , a wooden furniture surface polishing device, further comprising a workbench 13, the side wall of the workbench 13 is threadedly connected with a threaded column 18, and the two ends of the threaded column 18 are respectively fixedly connected with a limit block 17 and an adjusting disc 19, the The handle 9 is welded on the surface of the adjustment disc 19, and the limit block 17 can fix the furniture plate 14 on the workbench 13 to prevent it from shaking during the polishing process and improve the stability. The size of the plate 14 adjusts the position of the limit block 17 .

[0035] The bottom of the groove is fixedly connected with the bottom plate 15 through the spring 16. The number of the springs 16 is several and evenly distributed on the bottom of the groove. The longitudinal force received during the process prevents it from being damaged.

Embodiment 3

[0037] see figure 1 , a wooden furniture surface polishing device, also includes a slider 2 5, the top of the slider 2 5 is fixedly connected with a suspension 25, and the suspension 25 is slidably connected to the main shaft 2, and the main shaft 2 is welded to the beam 1 inner wall, the main shaft 2 can improve the stability of the slider 2 5 during the movement and prevent it from shaking.

[0038] The rest of the structure of this embodiment is the same as that of Embodiment 1.

[0039] The working principle of the present invention is: firstly put the furniture plate 14 on the workbench 13, and fix it by the stop block 17, then start the hydraulic cylinder 7, adjust the polishing wheel 20 to a suitable height, and then start the first servo The motor 21 and the polishing wheel 20 can polish the furniture plate 14 while moving along the axial direction of the first screw 6 . Next, the second servo motor 26 is started, so that the polishing wheel 20 can polish the furnitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com