Unmanned forklift route planning method and device

An unmanned forklift and routing technology, applied in the computer field, can solve problems such as inability to carry out cargo handling, achieve better routing planning results, save storage operations, and improve storage rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

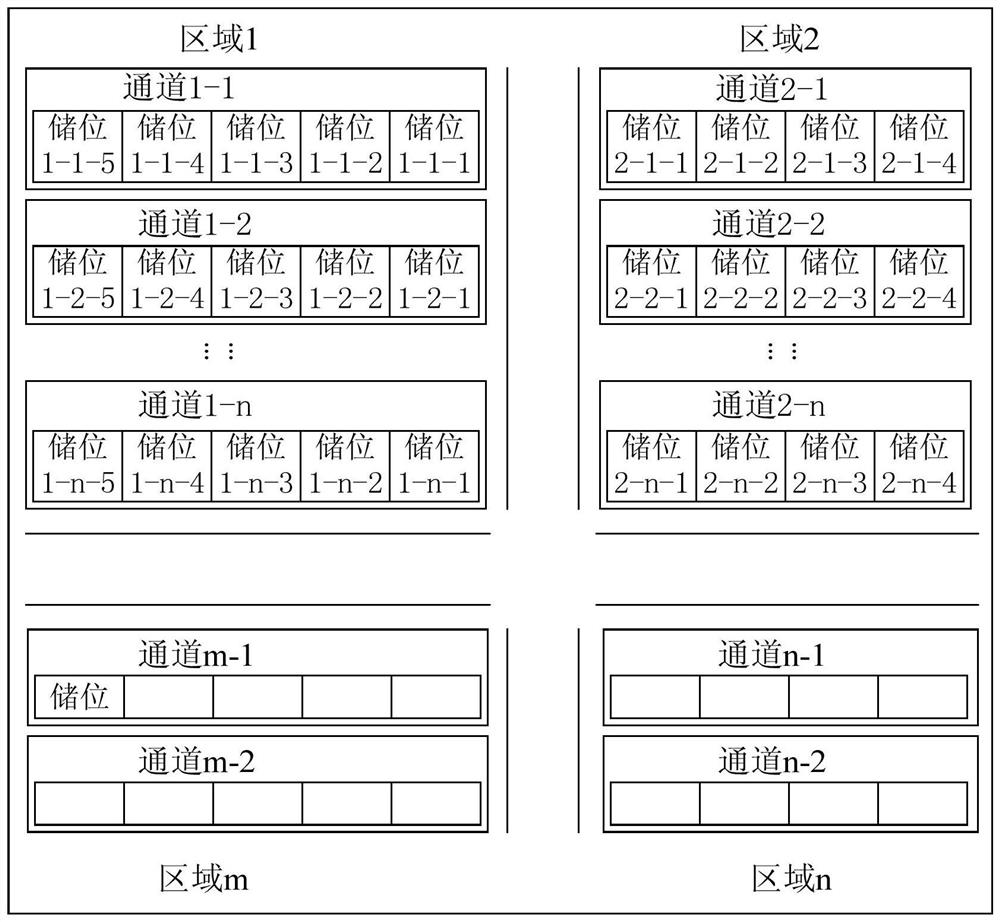

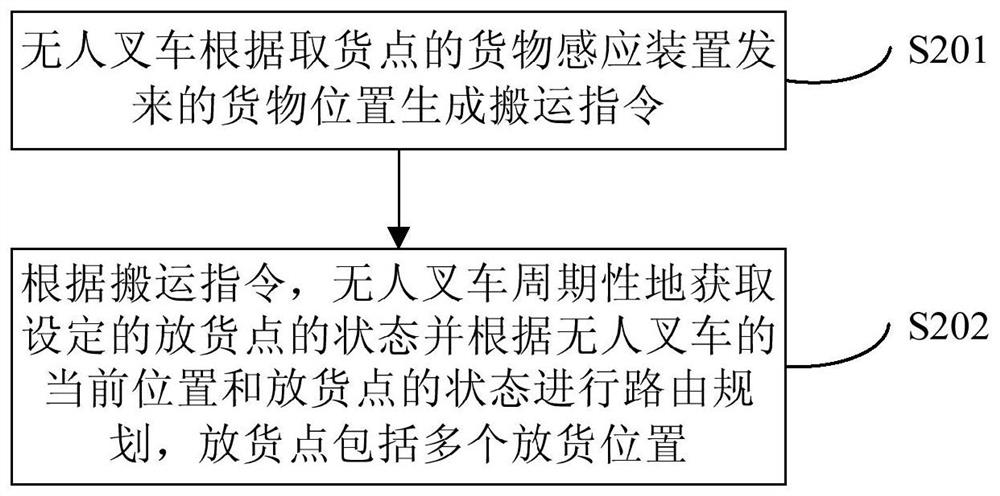

[0052] Example 1: The pick-up point is an area, and the delivery point is an area

[0053] The pick-up point is configured in the area, and the cargo sensing device at the pick-up point senses the arrival of the goods and notifies the on-board control system of the unmanned forklift of the location of the goods. The on-board control system of the unmanned forklift queries the location management information and performs routing planning. Specifically, the on-board control system of the unmanned forklift first obtains the configured delivery point area through the routing information management interface; The status of the bit includes: free, occupied and disabled, and the corresponding executable operations include: reserve, release, and enable; finally, the location of the delivery is determined according to the location and status of each storage location.

Embodiment 2

[0054] Embodiment 2: The pick-up point is an area, and the delivery point is a channel

[0055] When the pick-up point is configured in an area and the drop-off point is configured as a channel, the cargo sensing device at the pick-up point senses the arrival of the goods and notifies the on-board control system of the unmanned forklift of the location of the goods, and the on-board control system of the unmanned forklift queries the location management information and proceeds route planning. The difference from Embodiment 1 is that the vehicle-mounted control system of the unmanned forklift first obtains the configured delivery point channels through the routing information management interface; then directly obtains each storage location and its status of the delivery point channels according to the location management information That's it; finally, determine the delivery location according to the location and status of each storage location.

Embodiment 3

[0056] Embodiment 3: The pick-up point is the channel, and the delivery point is the area

[0057] When the pick-up point is configured as an aisle and the drop-off point is configured as an area, the cargo sensing device at the pick-up point senses the arrival of the goods and notifies the on-board control system of the unmanned forklift about the location of the goods, and the on-board control system of the unmanned forklift queries the location management information and proceeds Routing planning; in addition, after the goods sensing device at the pick-up point senses the arrival of the goods, it can only notify the on-board control system of the unmanned forklift that there are goods waiting to be picked up in this channel. The sensor device (for example: photoelectric sensor) of the human forklift itself determines the location of the goods according to the data of the sensor device, and then the on-board control system of the unmanned forklift queries the location managem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com