Intelligent operation method for automobile part warehouse

A technology of auto parts and intelligent pallet trucks, which is applied in the direction of instruments, data processing applications, logistics, etc., can solve the problems of low precision of first-in-first-out, inventory differences, homing and dislocation, etc., to eliminate wrong picking and simple operation , the effect of increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

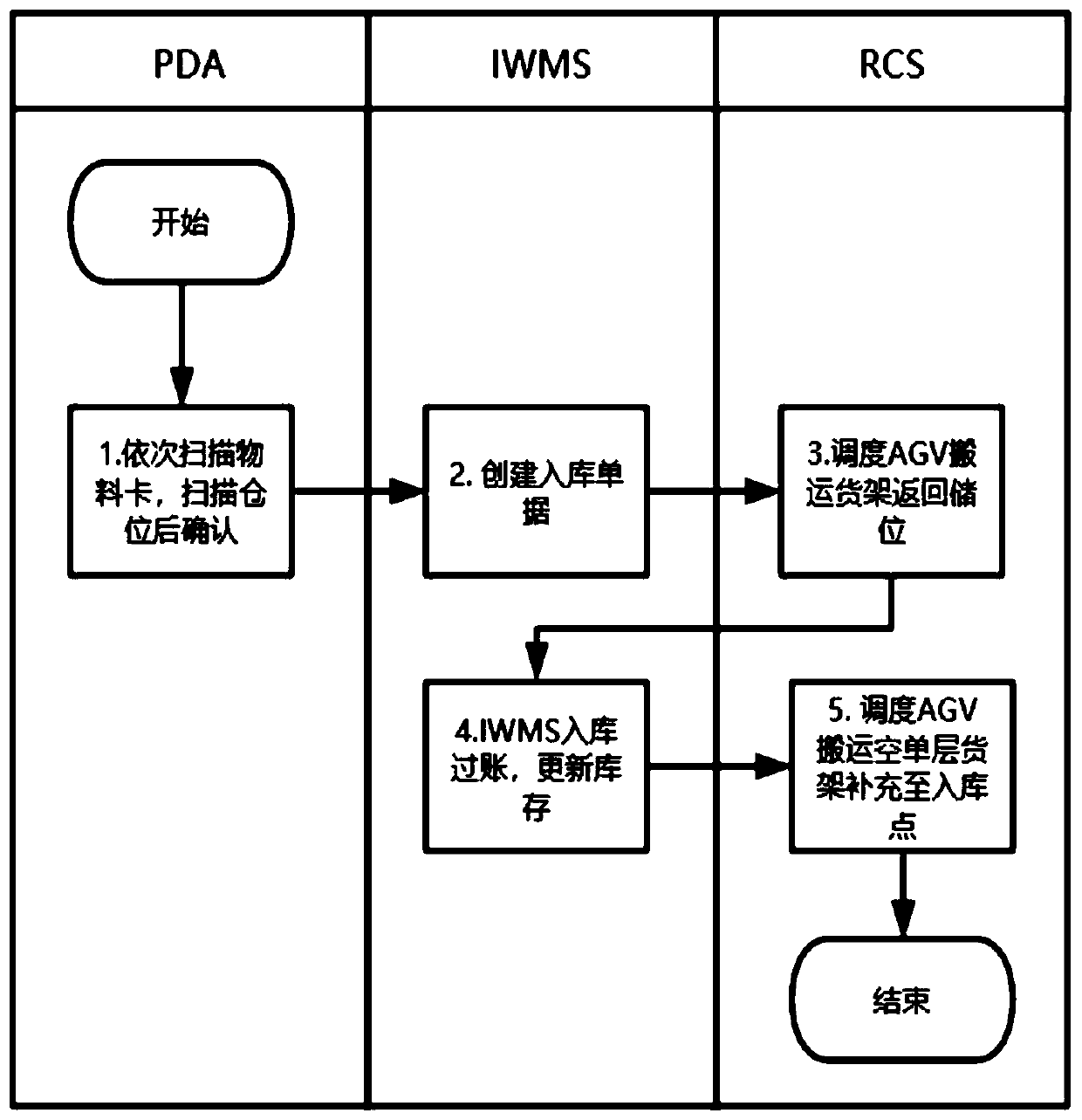

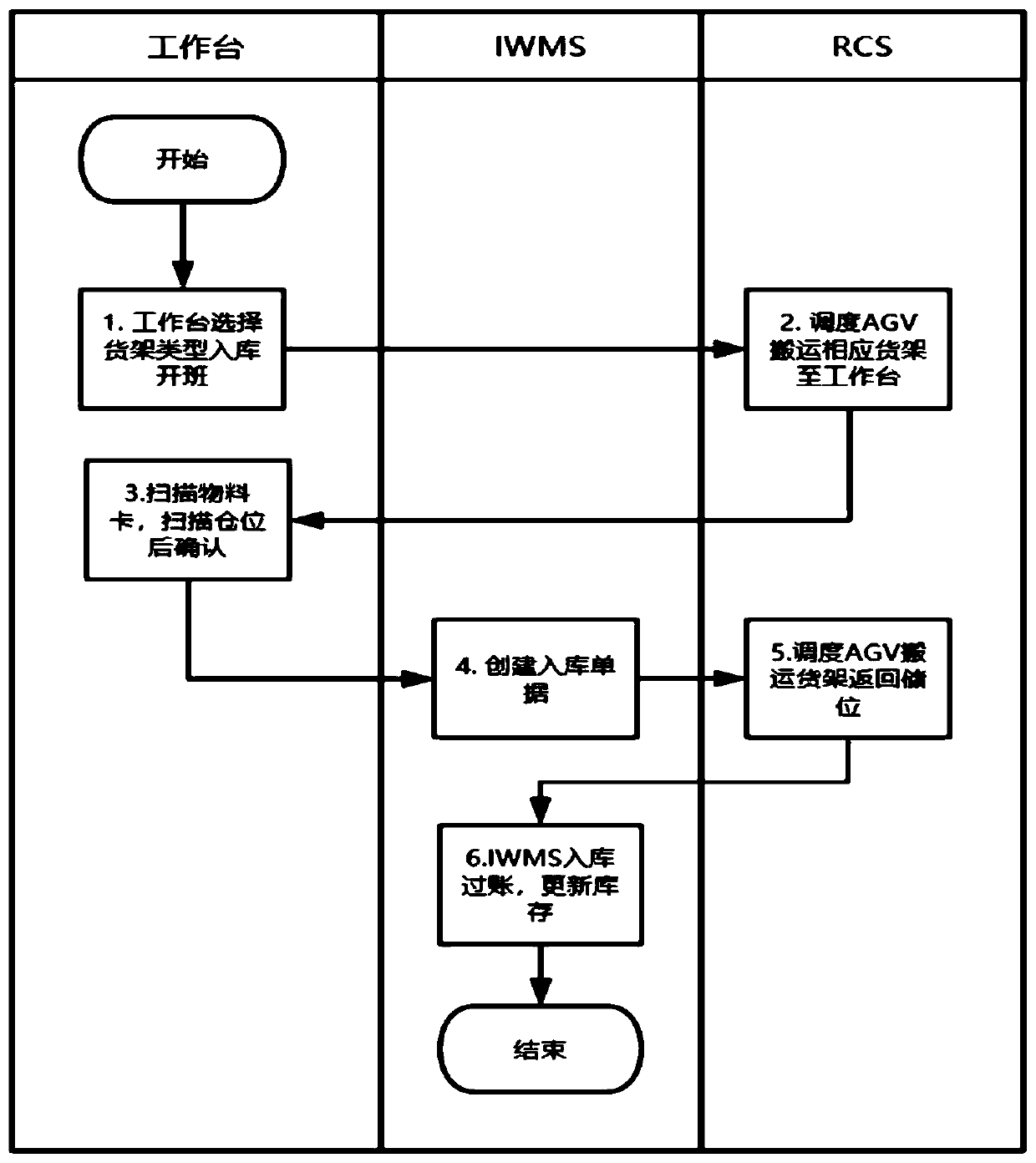

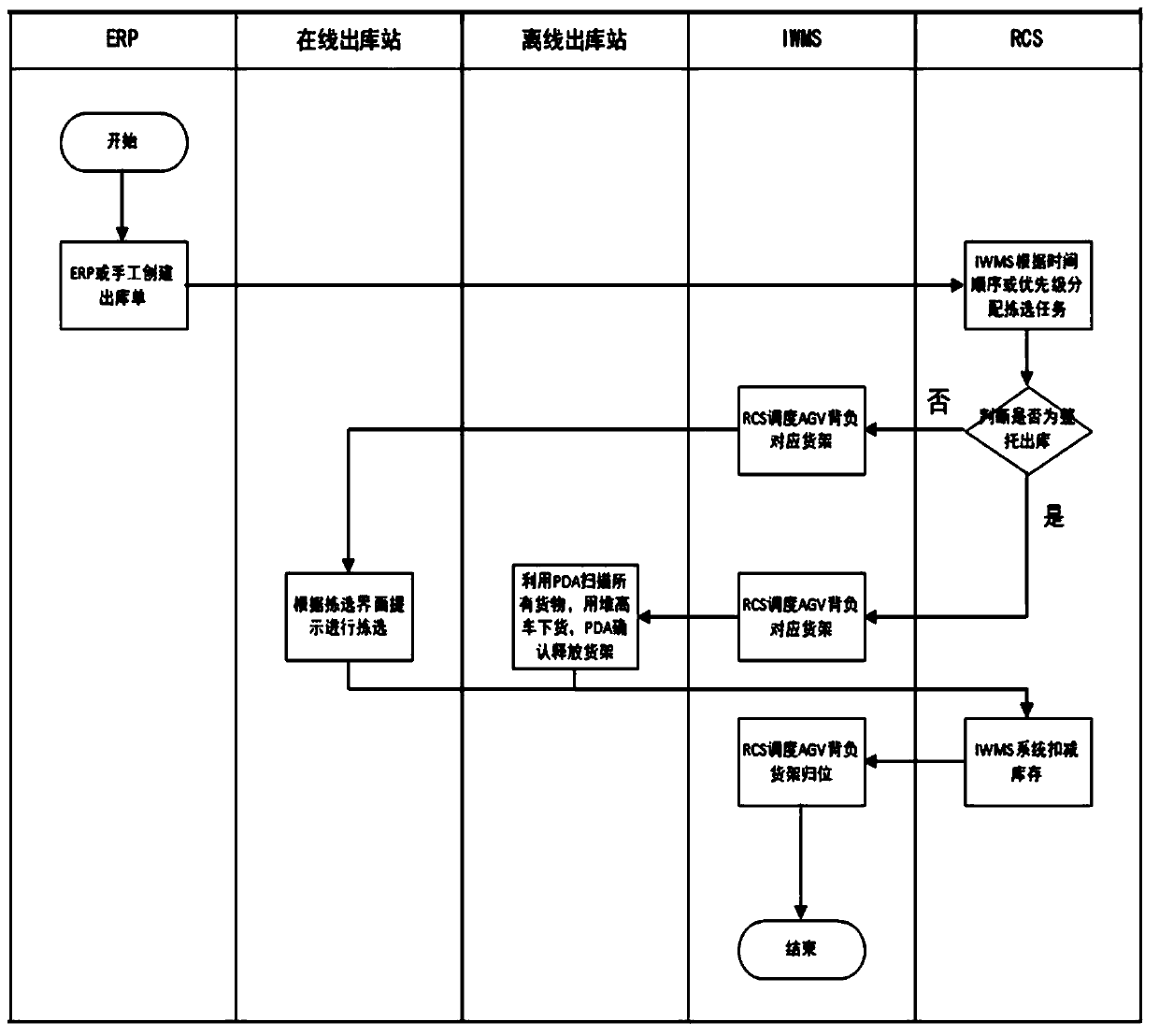

[0049] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0050] The present invention adds equipment scheduling management system and handling robot on the basis of warehouse management system, uses warehouse management system as the brain of auto parts storage warehouse, equipment scheduling system as nerve hub, and handling robot as executive mechanism to realize auto parts Intelligent operation of the warehouse.

[0051] Warehouse management system (IWMS): Manage warehouse accounts, record parts inventory information; warehouse location allocation, allocate warehouse locations according to the temperature and temperature of parts used, and realize warehouse location liberalization; first-in-first-out management, according to parts Establish specific batch information at the warehouse time, and allocate strictly according to the batch when picking; docum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com