Method for controlling at least one radial fan in a refrigeration plant and radial fan

一种制冷设备、径流式的技术,应用在用于弹性流体的泵送装置的部件、泵控制、机械设备等方向,能够解决径流式风机过载、损坏、未最优地充分利用运行区域等问题,达到完整检控和监控的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

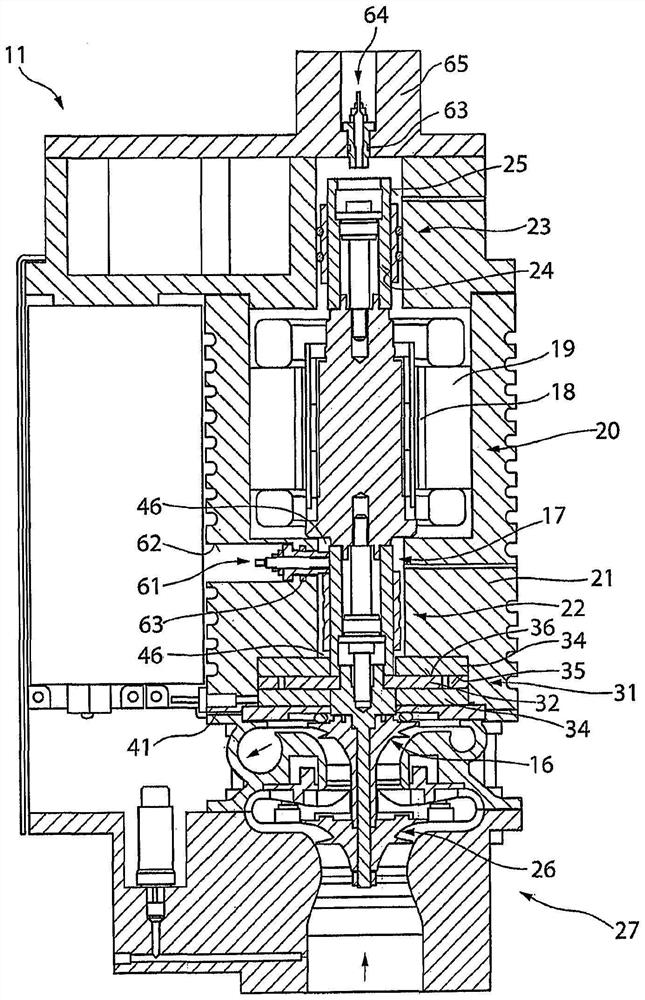

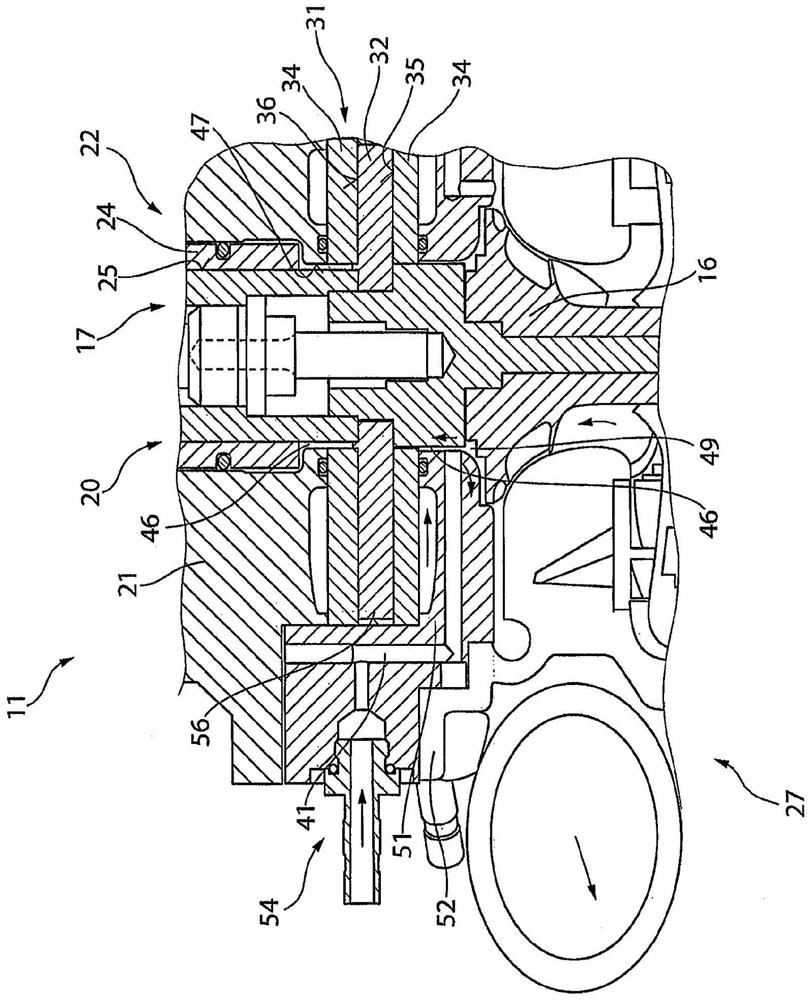

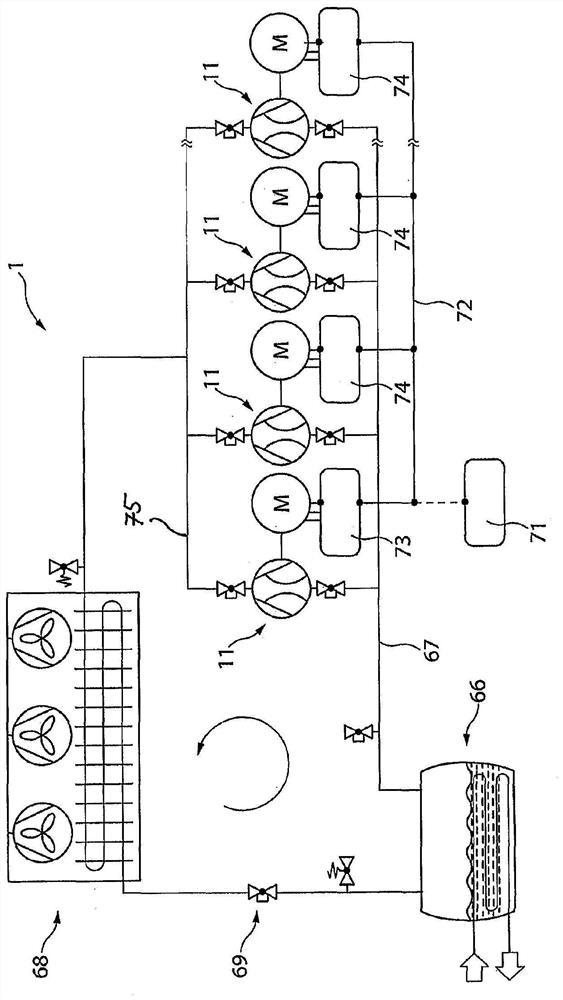

[0023] exist figure 1 , a schematic sectional view of the radial fan 11 is shown. By means of the radial fan 11 , the refrigerant is accelerated radially by the at least one impeller 16 , 26 of the compressor 27 and is deflected into the circuit of the refrigeration plant 1 , which is exemplified in the image 3 shown in.

[0024] By means of the radial fan 11 , the cooling medium is accelerated in the radial direction by the at least one impeller 16 , 26 of the compressor 27 and is led compressed into the gas pressure line 75 on the compression side of the refrigeration system 1 ( image 3 ). The impellers 16 , 26 are located on the shaft 17 which is driven by the motor 20 in the central region of the motor housing 21 . The motor 20 consists of the rotor 18 connected to the shaft 17 and the stator 19 fixed on the motor housing 21 . The area arranged outside the impellers 16 , 26 as seen from the shaft 17 forms the pressure side of the blower. Radial bearings 22 , 23 , in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com