Method for controlling at least one radial fan in refrigeration plant and radial fan

A refrigeration equipment, radial flow technology, applied to the components of the pumping device for elastic fluid, pump control, mechanical equipment, etc., can solve the problem of radial fan overload, damage, not making full use of the operating area, etc. , to achieve the effect of complete prosecution and monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

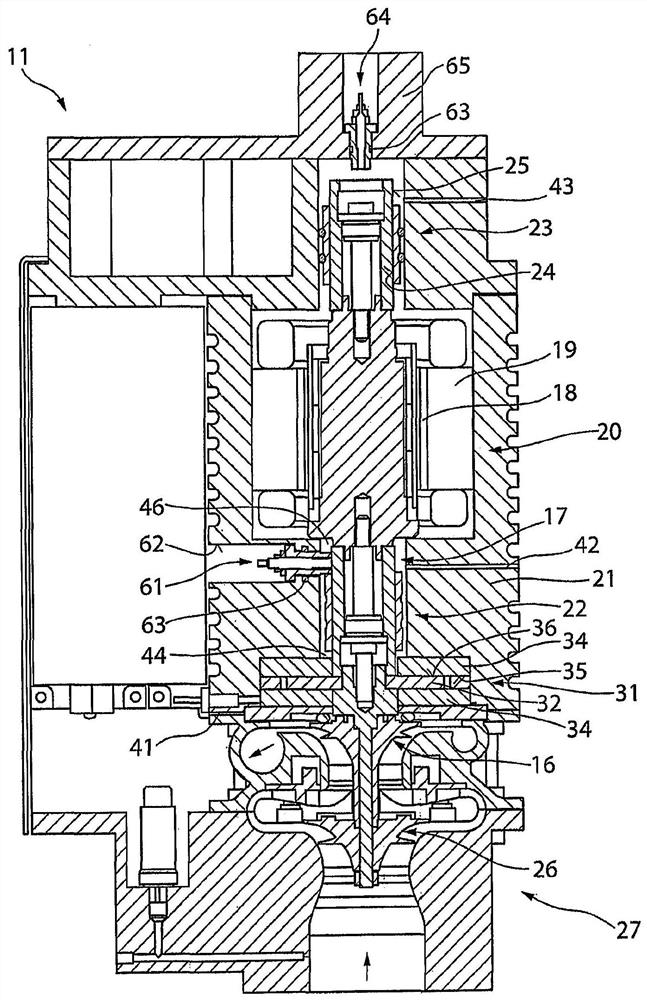

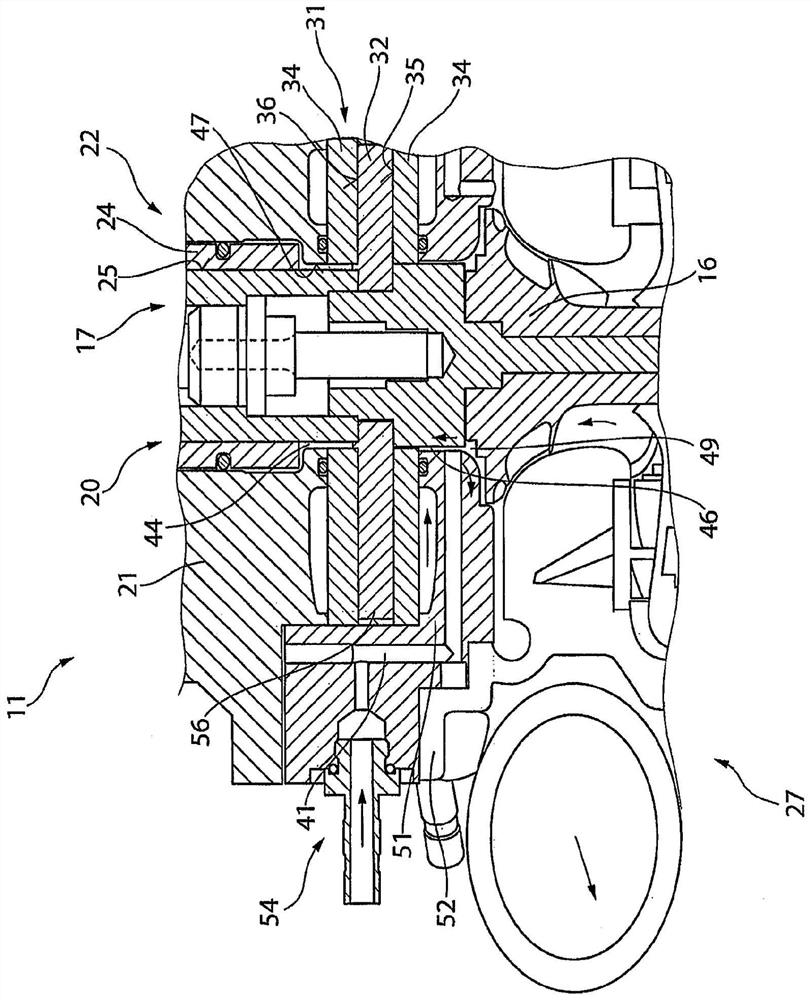

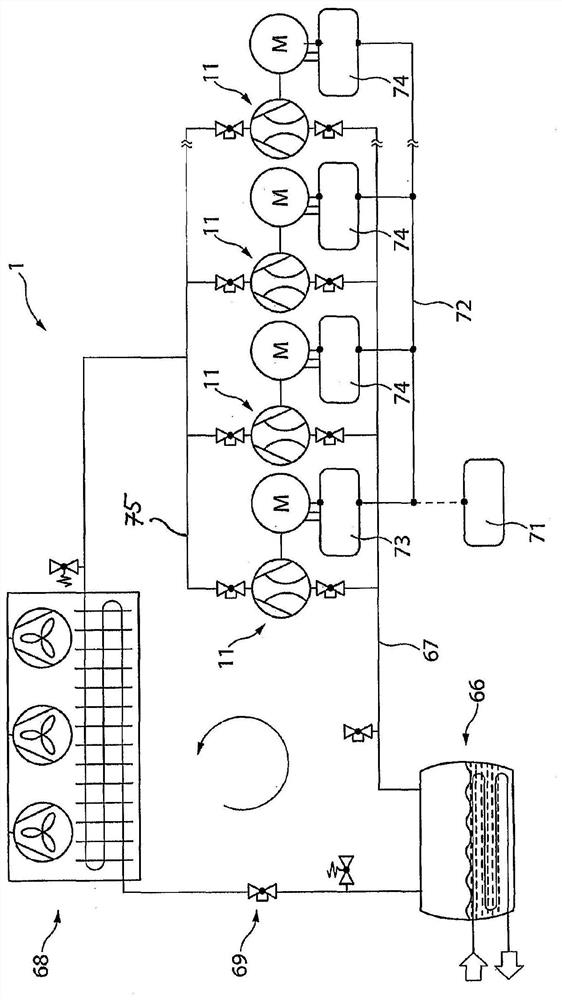

[0023] exist figure 1 , a schematic cross-sectional view of a radial fan 11 is shown. Via the radial fan 11 , the refrigerant is accelerated radially by at least one impeller 16 , 26 of the compressor 27 and deflected into the circuit of the refrigeration plant 1 , for example in image 3 shown in .

[0024] Via the radial fan 11 , the cooling medium is accelerated radially by at least one impeller 16 , 26 of the compressor 27 and guided compressed into the gas pressure line 75 on the compression side of the refrigeration device 1 ( image 3 ). The impellers 16 , 26 are located on a shaft 17 which is driven by a motor 20 in the central region of the motor housing 21 . The motor 20 consists of a rotor 18 connected to a shaft 17 and a stator 19 fastened to a motor housing 21 . The area arranged outside the impellers 16 , 26 as viewed from the shaft 17 forms the pressure side of the blower. Radial bearings 22 , 23 , in particular a lower radial gas bearing 22 and an upper ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com