A winding mechanism operation control device and control method

A winding mechanism and operation control technology, which is applied in the field of winding mechanism operation control devices, can solve problems such as the inability to monitor the running state of objects wound by the winding mechanism in real time, and achieve the goal of avoiding medium loss and abnormal state of the medium, improving reliability and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

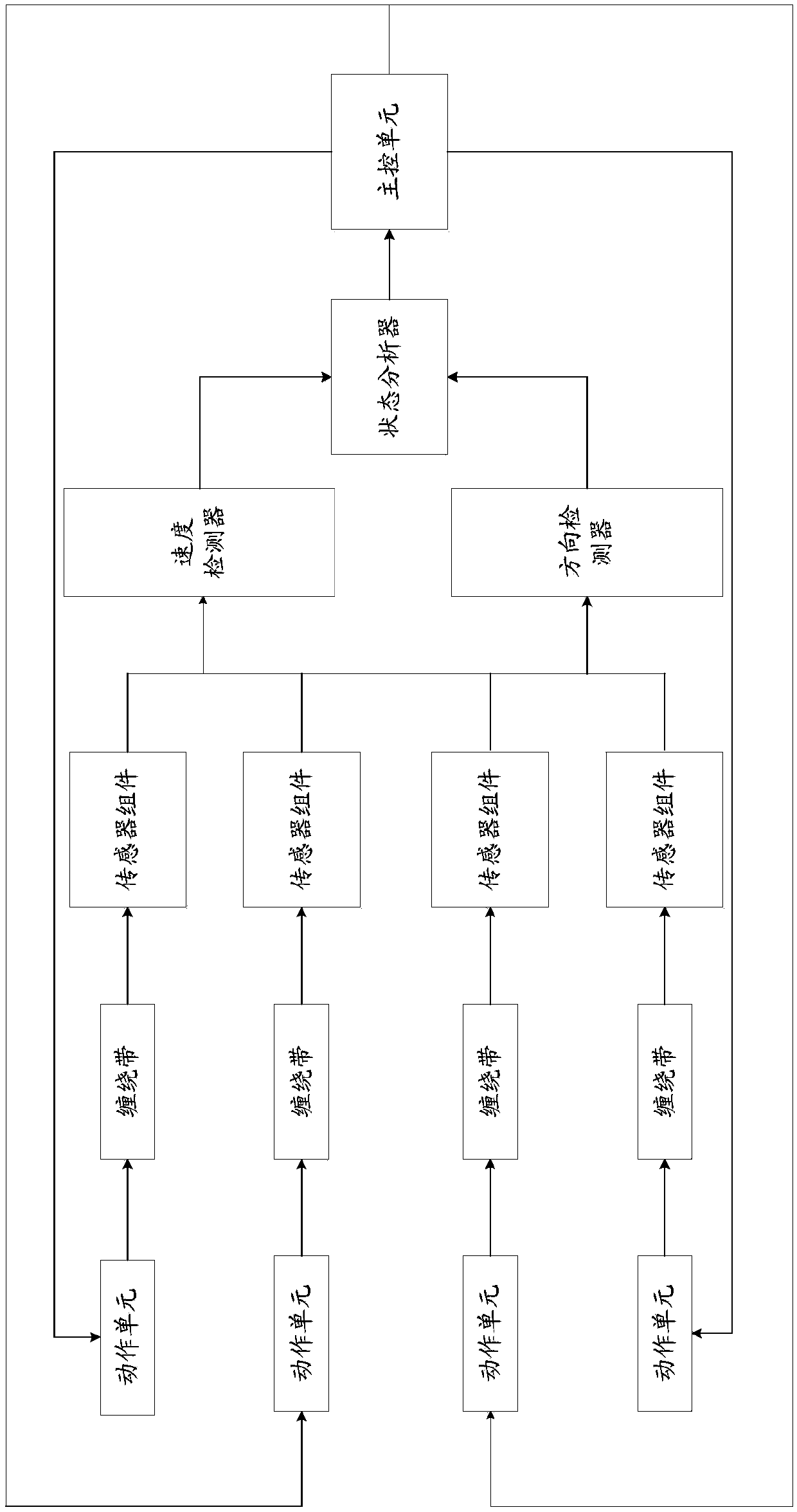

[0033] figure 1 It is a structural block diagram of the winding mechanism operation control device provided by the embodiment of the present invention, and is described in detail as follows:

[0034] A winding mechanism operation control device, including each action unit that drives the winding mechanism to run, and also includes:

[0035] The sensor component is used to collect the running information of the winding belt;

[0036] a speed detector connected to the sensor assembly, used for speed detection according to the operation information output by the sensor assembly;

[0037] a direction detector connected to the sensor component, used for direction detection according to the operation information output by the sensor component;

[0038] A state analyzer connected to the direction detector and the speed detector respectively, used to determine the operation of the winding mechanism based on the running speed information detected by the speed detector and the running...

Embodiment 2

[0085] Figure 6 It is an implementation flowchart of the control method provided by the embodiment of the present invention, and is described in detail as follows:

[0086] S601, the sensor assembly collects the running information of the winding belt;

[0087] S602. The speed detector performs speed detection according to the running information collected by the sensor component, and outputs the detected running speed information to the state analyzer;

[0088] S603. The direction detector performs direction detection according to the running information collected by the sensor component, and outputs the detected running direction information to the state analyzer;

[0089] S604, the state analyzer obtains the current winding belt running information according to the running speed information detected by the speed detector and the running direction information detected by the direction detector, and combines the current winding tape running information with the issued comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com