Paint uniform brushing device for iron bucket

A technology for paint and iron buckets, which is applied in the field of iron bucket paint brushing devices, which can solve the problems of uneven manual painting and waste of paint, and achieve the effect of conveniently putting in and taking out iron buckets and saving paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

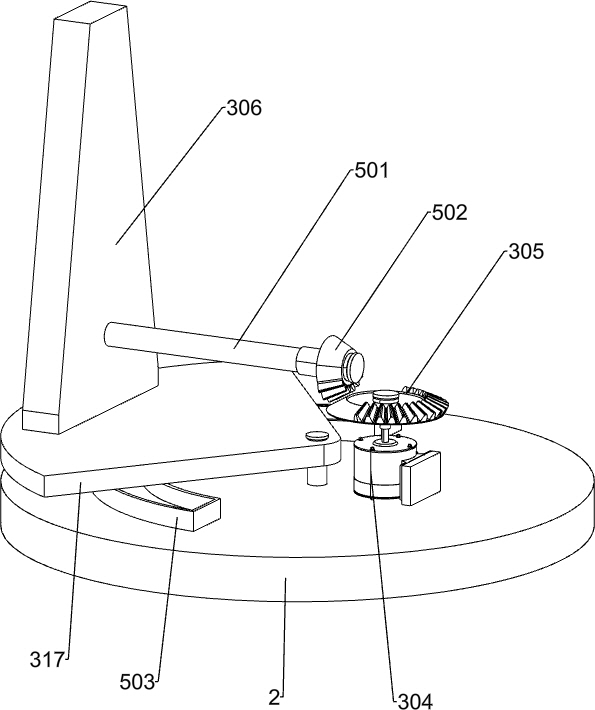

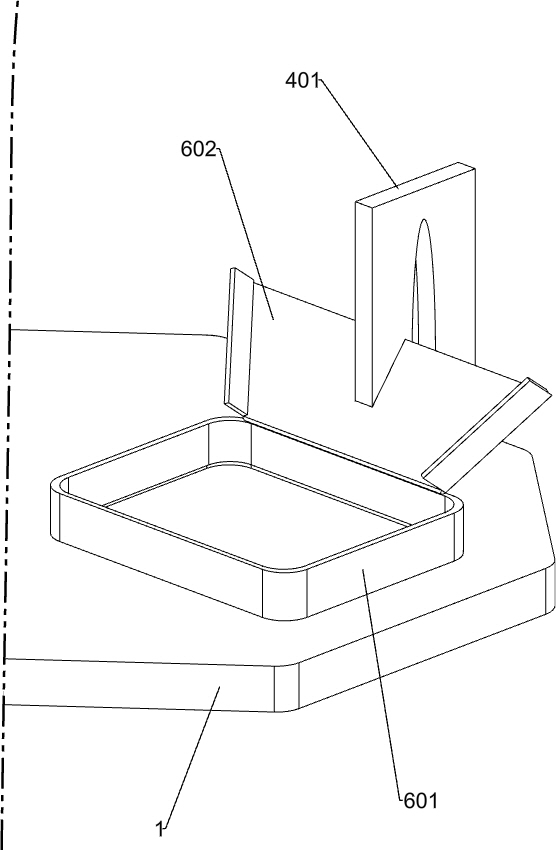

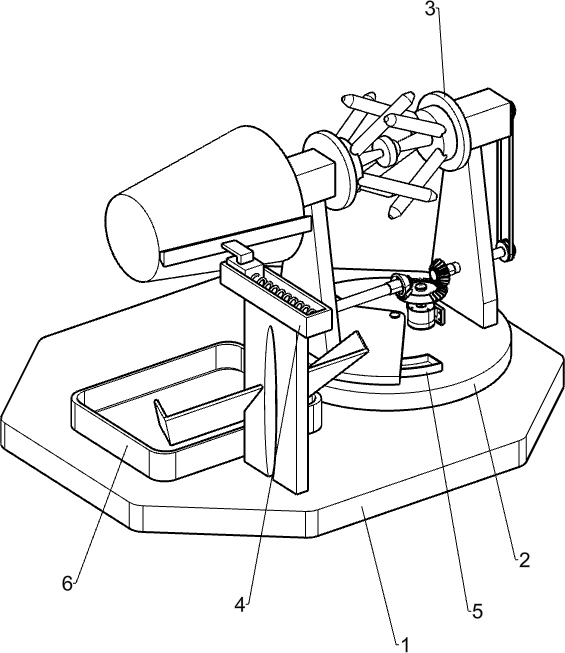

[0027] A kind of iron barrel paint evenly brushing device, such as Figure 1-9 As shown, it includes a base plate 1, a fixed plate 2, a rotating placement mechanism 3 and a brushing mechanism 4. The upper right side of the base plate 1 is provided with a fixed plate 2, and the left and right sides of the upper part of the fixed plate 2 are provided with a rotating placement mechanism 3. A brushing mechanism 4 is provided on the front side of the left part.

[0028] When people need to paint the iron barrel, first fix the iron barrel on the rotating placement mechanism 3, then start the rotating placing mechanism 3, and the brushing mechanism 4 continuously paints the iron barrel, and when the iron barrel is painted, turn off the rotating Place the mechanism 3, just take off the iron bucket, if you need to paint the iron bucket again, repeat the above steps.

[0029] The rotating placement mechanism 3 includes a first mounting plate 301, a rotating rod 302, a first bevel gear ...

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 and Figure 7-9As shown, a swing mechanism 5 is also included. The upper left side of the fixed plate 2 is provided with a swing mechanism 5. The swing mechanism 5 is in contact with the bottom of the swing plate 317. The swing mechanism 5 includes a cross bar 501, a third bevel gear 502, and an arc guide rail. 503, the second slide block 504 and the second spring 505, the second mounting plate 306 bottom () rotation type is provided with a crossbar 501, the right end of the crossbar 501 is provided with a third bevel gear 502, the third bevel gear 502 and the second bevel Gear 305 cooperates, and the left side of fixed plate 2 top is provided with arc guide rail 503, and arc guide rail 503 is positioned at pendulum plate 317 below, and the inner sliding type of arc guide rail 503 is provided with second slide block 504, and the front end of second slide block 504 and arc A second spring 505 is connected between the inner fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com