A damage repair method for large-scale holes in complex metal structures

A metal structure and damage repair technology, applied in metal processing equipment, manufacturing tools, machine tools suitable for grinding workpiece edges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

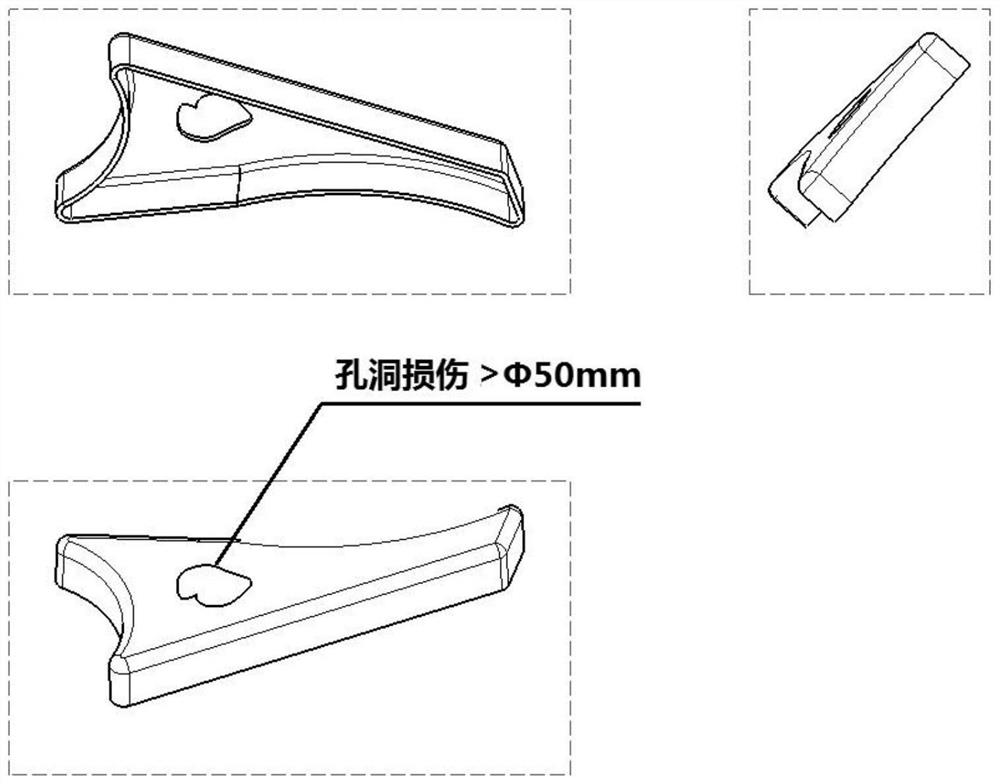

[0047] Such as figure 1 As shown, the typical part structure of a certain type of aircraft is made of cast aluminum alloy (ZL116) material, and holes are damaged due to accidents, and the size is larger than Φ50mm.

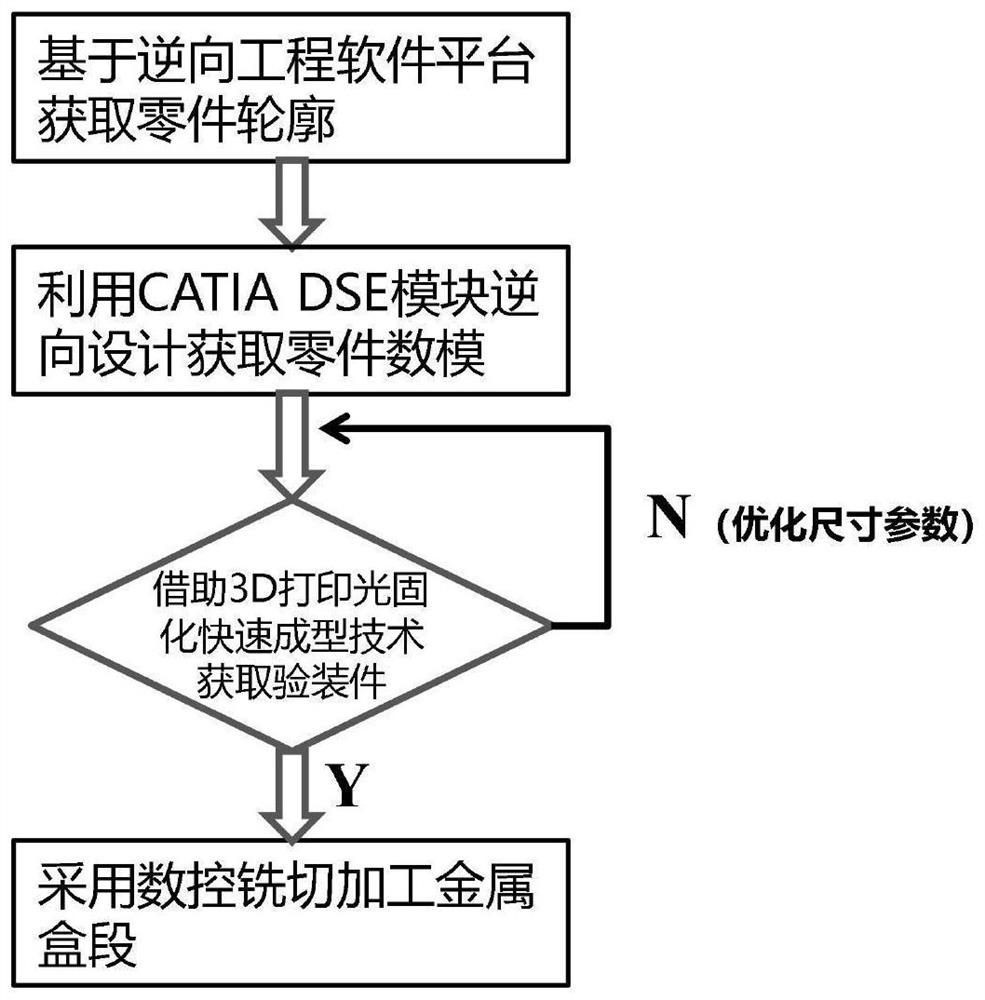

[0048] The invention implements a method for repairing the damage of the large-sized hole in the complex metal structure, so as to meet the requirements of structural function and load-bearing use. Specific steps are as follows:

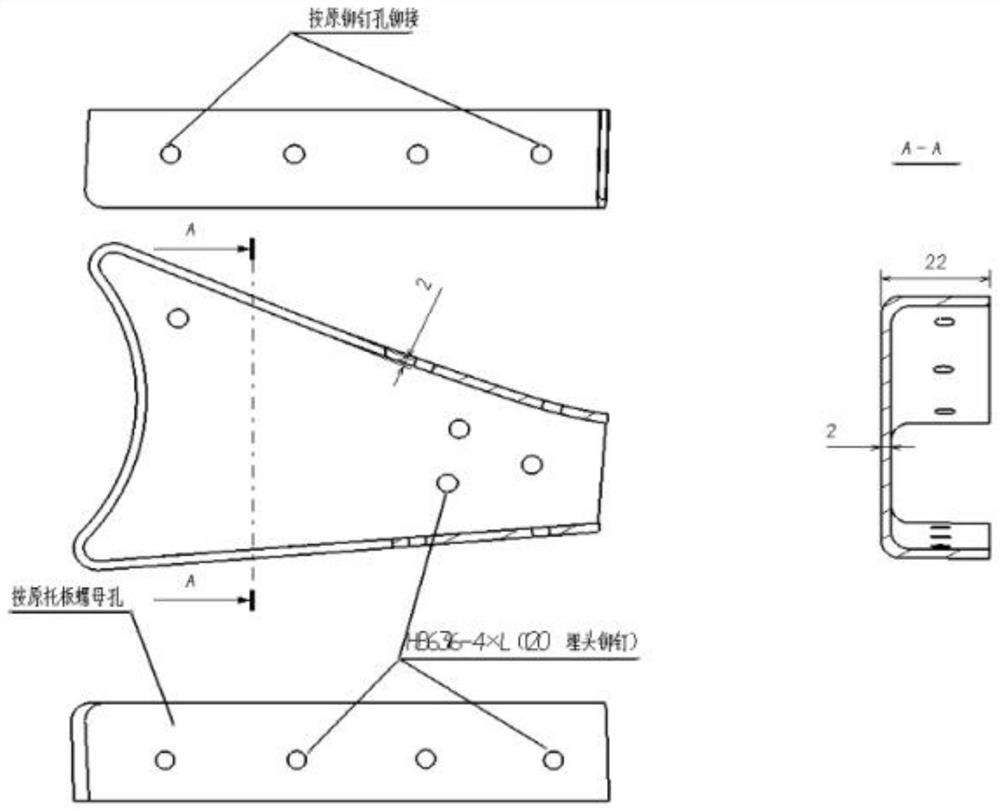

[0049] (1) Determine the number of cladding layers and the thickness of the reinforced box section for composite material bonding repair by consulting the structural drawings or the web thickness parameters of the bulkhead determined by the digital model, and according to the remaining...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com