A connection structure between balance beams on a crane

A technology for connecting structures and balancing beams, applied to connecting components, mechanical equipment, load suspending elements, etc., can solve problems such as lowering the safety of the upper balancing beam, loosening nuts, and reducing the utility of the balancing beam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

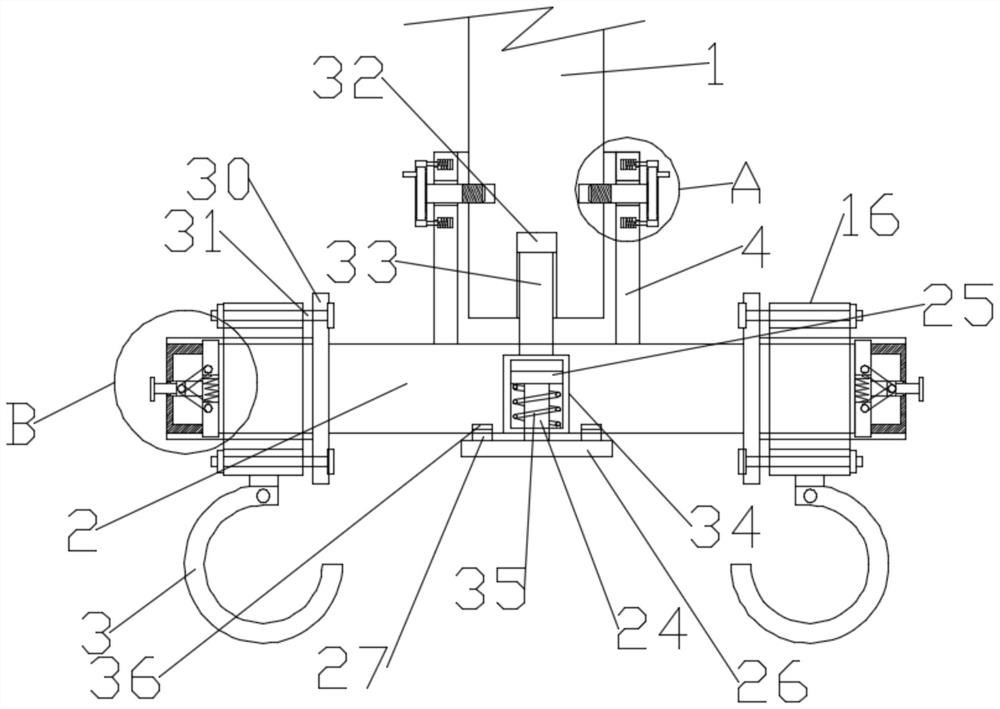

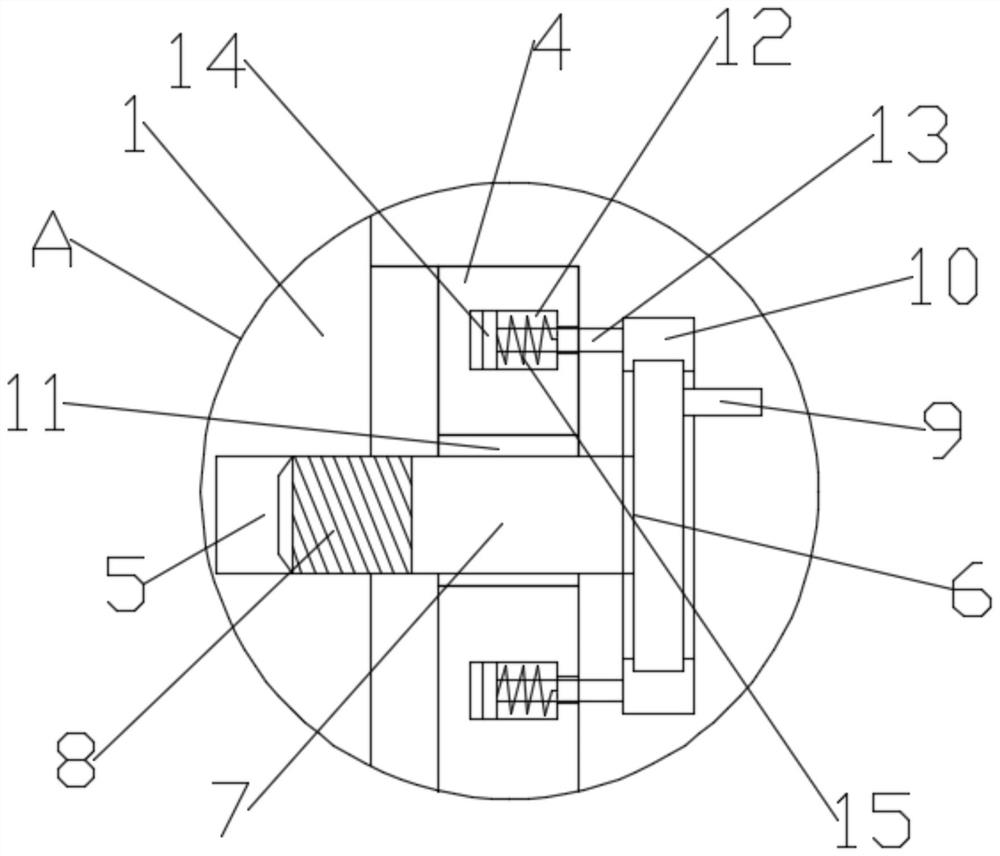

[0026] Such as Figure 1-5 As shown, in the embodiment provided by the present invention, a connection structure between balance beams on a crane includes a connecting column 1 and a balance beam main body 2, and a connection seat 4 is fixedly arranged on the upper surface of the balance beam main body 2, so that The bottom end of the connecting column 1 extends into the connecting seat 4, and the connecting column 1 extending into the connecting seat 4 is respectively connected and fixed through the first mounting assembly and the second mounting assembly; the balance beam main body 2 Supporting sliding sleeves 16 are detachably installed at both ends of the third mounting assembly, and the bottom ends of the two supporting sliding sleeves 16 are fixedly provided with a spreader 3 .

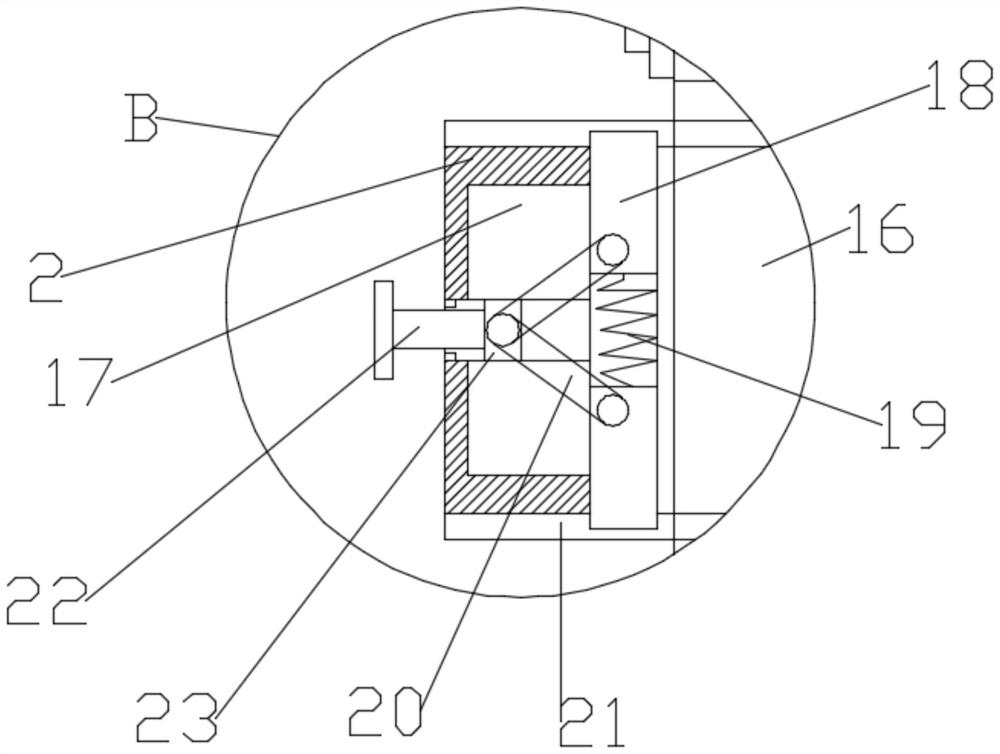

[0027] Specifically, in the embodiment provided by the present invention, the outer rings at both ends of the balance beam main body 2 are fixedly sleeved with fixed ring blocks 30, and the supp...

Embodiment 2

[0030] Such as Figure 1-5 As shown, in the embodiment provided by the present invention, a connection structure between balance beams on a crane includes a connecting column 1 and a balance beam main body 2, and a connection seat 4 is fixedly arranged on the upper surface of the balance beam main body 2, so that The bottom end of the connecting column 1 extends into the connecting seat 4, and the connecting column 1 extending into the connecting seat 4 is respectively connected and fixed through the first mounting assembly and the second mounting assembly; the balance beam main body 2 Supporting sliding sleeves 16 are detachably installed at both ends of the third mounting assembly, and the bottom ends of the two supporting sliding sleeves 16 are fixedly provided with a spreader 3 .

[0031]Specifically, in the embodiment provided by the present invention, the outer rings at both ends of the balance beam main body 2 are fixedly sleeved with fixed ring blocks 30, and the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com