Bending die for electric control box of air conditioner outdoor unit

A bending mold and electric control box technology, applied in the field of mold manufacturing, can solve the problems of large capital investment and poor practicability, and achieve the effect of improving safety, high safety, reducing capital investment and inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

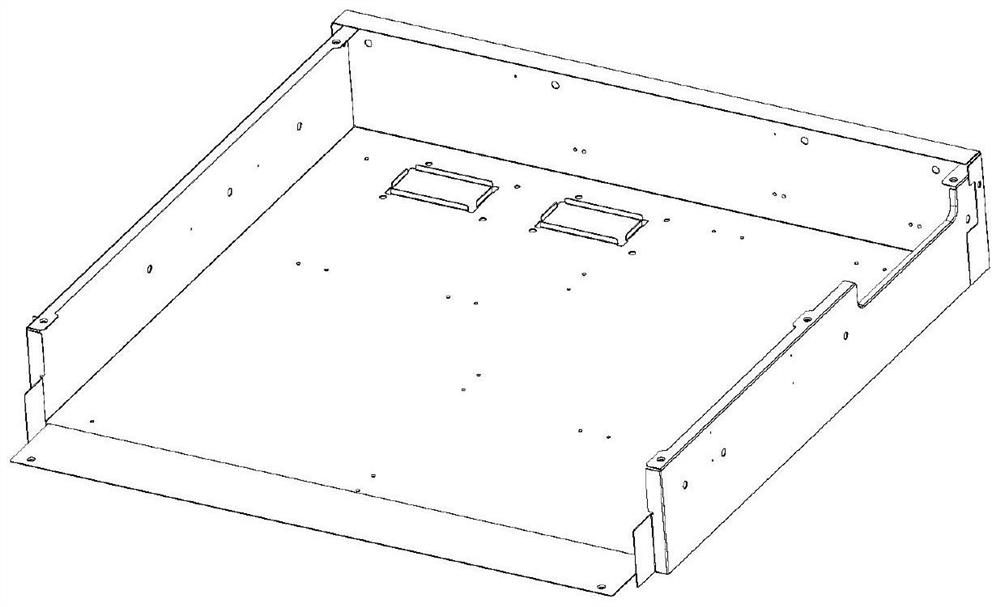

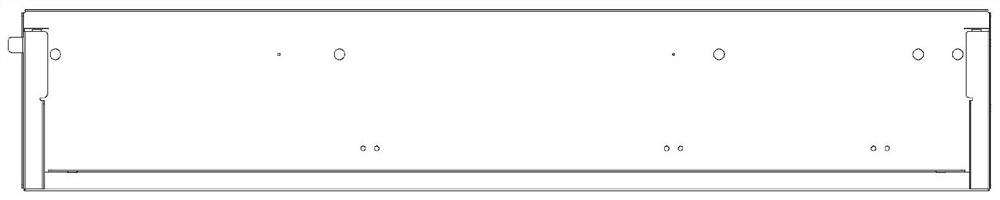

[0031] A bending die for an external electric control box of an air conditioner, which is used to bend a prefabricated board 11 of the electric control box to obtain an electric control box shell, the structure of which is as follows: Figure 4 and Figure 5 As shown, it includes an upper pallet 1, an upper foot 2, an upper die base 3, an upper backing plate 4, an upper formwork 5, a lower release plate 6, a lower die base 7, a lower foot 8 and a lower pallet 9 and the installation A guide unit 10 is provided between the upper die base 3 and the lower die base 7. Both ends of the guide unit 10 are connected to the upper die base 3 and the lower die base 7 respectively. The electric control box prefabricated board 11 is installed on the lower release board 6, and the upper The template 5 is a detachable structure.

[0032] The structure of the upper template 5 is as follows Image 6 and Figure 7 As shown, it includes an intermediate fixing block 501, a first bending block 5...

Embodiment 2

[0037] The lower release plate 6 is provided with a positioning convex point 601 , and the electric control box prefabricated board 11 is provided with a positioning concave point, and the positioning convex point 601 corresponds to the position of the positioning concave point.

Embodiment 3

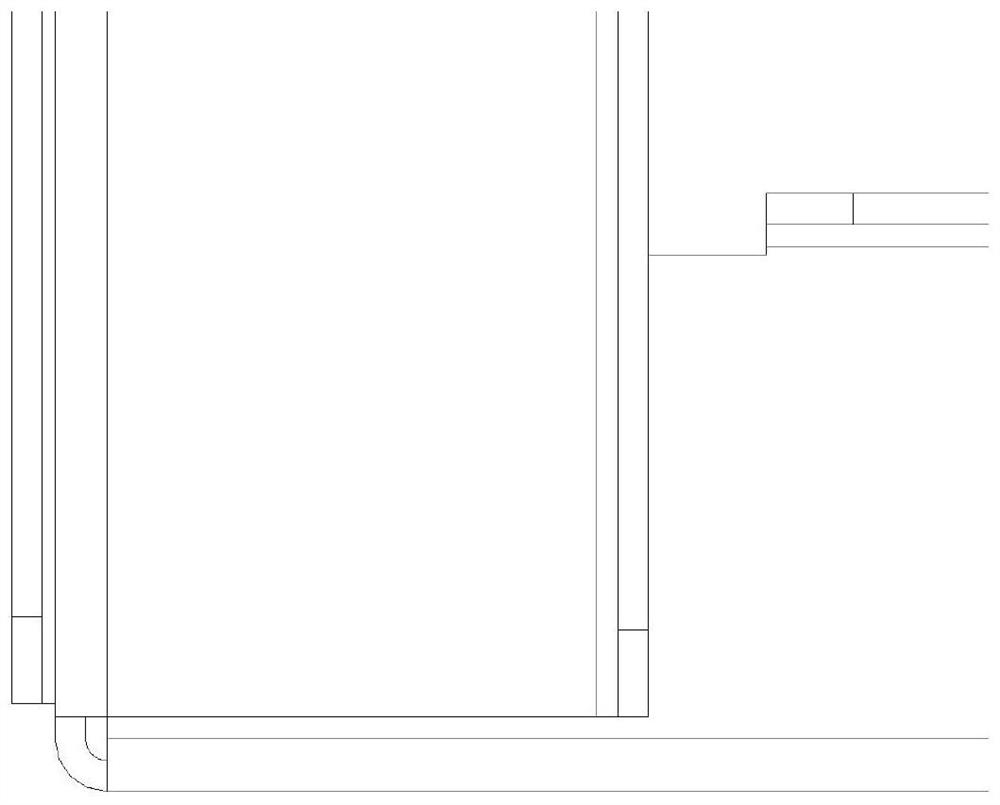

[0039] The guide unit 10 includes a guide unit base 1001, a guide post 1002, a guide sleeve 1003 and a return spring 1004. The guide unit base 1001 is fixed on the upper die base 3, the guide post 1002 is fixed on the guide unit base 1001, and the guide sleeve 1003 is fixed on the lower die On the seat 7 , the guide sleeve 1003 is sleeved on the guide post 1002 , and the return spring 1004 is sleeved on the guide post 1002 , and is installed between the guide unit base 1001 and the guide sleeve 1003 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com