A Harmonic Drive Reduction Mechanism

A deceleration mechanism and harmonic transmission technology, which is applied in the transmission device, transmission device parts, mechanical equipment, etc., can solve the problems of difficult replacement, wear of the outer ring gear of the flexible gear, rotation misalignment of the flexible gear and the rigid gear, etc., and achieve convenience The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

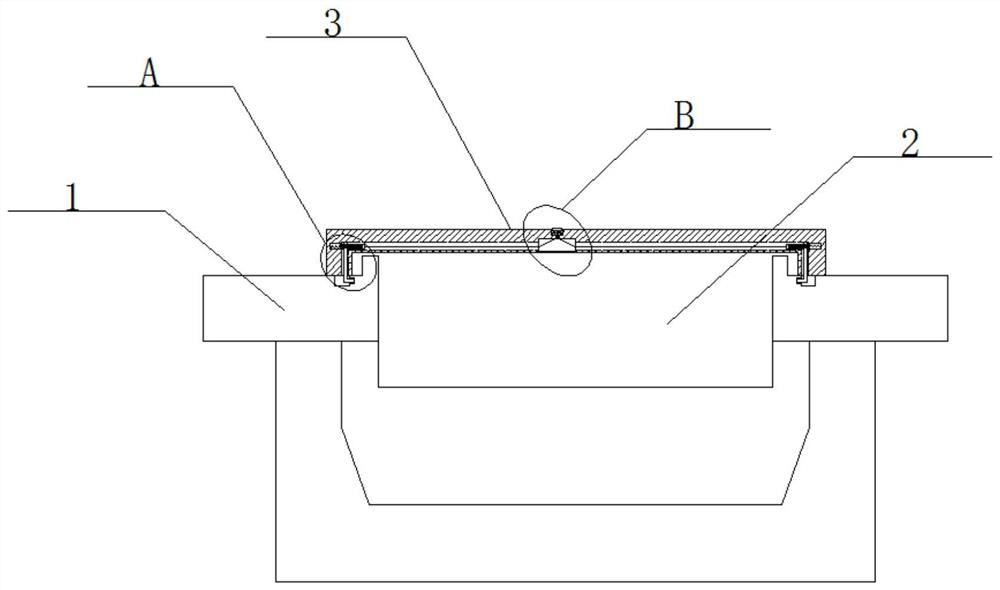

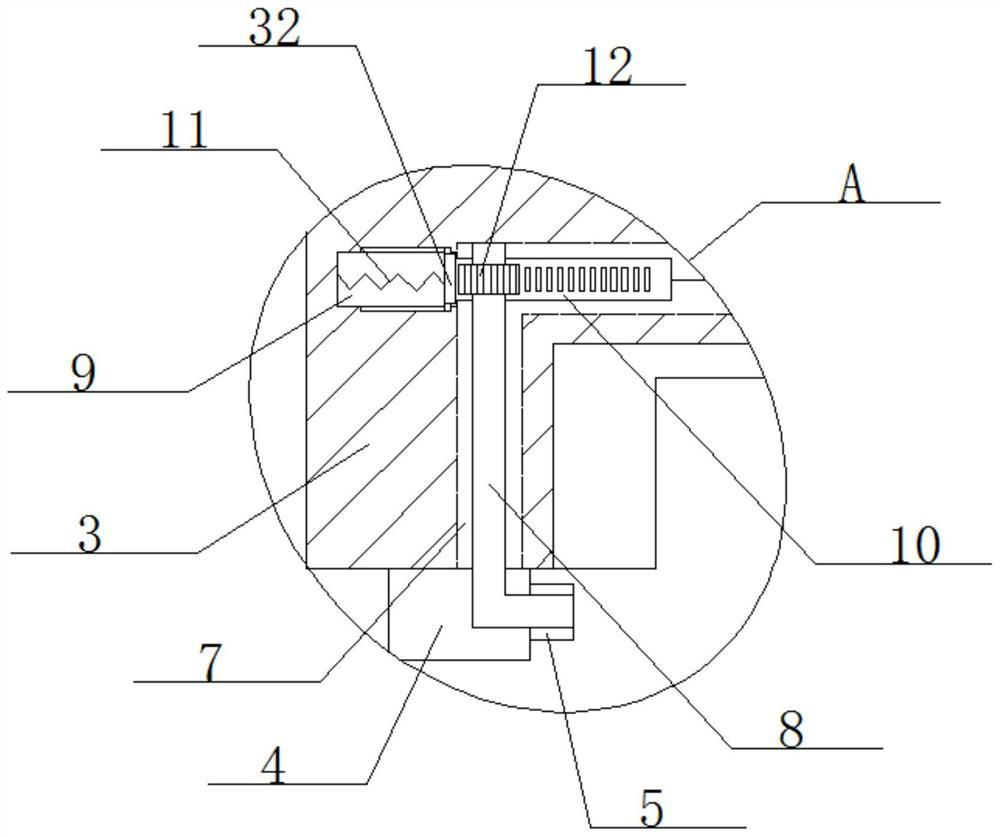

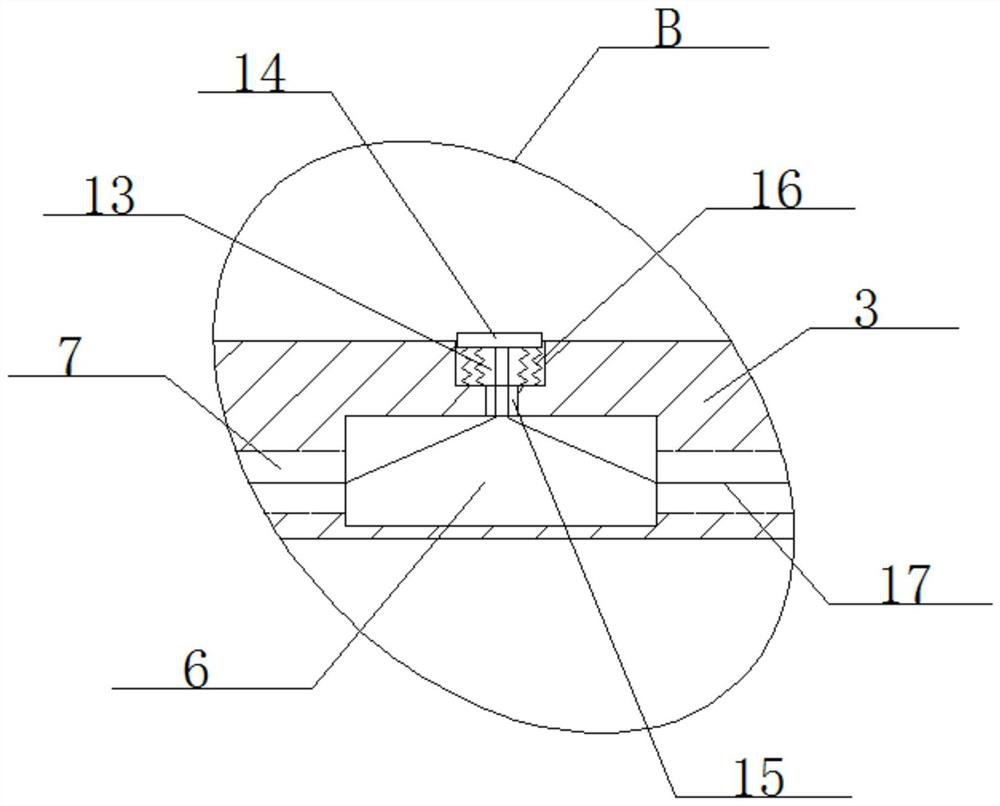

[0025] refer to Figure 1-5 , a harmonic drive reduction mechanism, including a rigid gear 1, a flexible gear 2 and an anti-displacement cover 3, two grooves 4 are respectively opened on the rigid gear 1, and the inner walls of the two grooves 4 are close to each other. An arc-shaped groove 5 is provided, and a cavity 6 is provided inside the anti-displacement cover 3, and an L-shaped hole 7 is provided on the inner wall of both sides of the cavity 6, and an L-shaped hole 7 is rotated on the inner wall of the top side of the L-shaped hole 7. Rod 8, and the bottom end of the L-shaped rod 8 extends into the arc-shaped groove 5, the L-shaped rod 8 is compatible with the arc-shaped groove 5, and two L-shaped holes 7 are provided with long grooves on the inner wall of the side away from each other 9, and a movable block 32 is slidably installed in the long groove 9, and a rack 10 is fixedly installed on the side where the two movable blocks 32 are close to each other, and a movable...

Embodiment 2

[0032] refer to Figure 1-5, a harmonic drive reduction mechanism, including a rigid gear 1, a flexible gear 2 and an anti-displacement cover 3, two grooves 4 are respectively opened on the rigid gear 1, and the inner walls of the two grooves 4 are close to each other. An arc-shaped groove 5 is provided, and a cavity 6 is provided inside the anti-displacement cover 3, and an L-shaped hole 7 is provided on the inner wall of both sides of the cavity 6, and an L-shaped hole 7 is rotated on the inner wall of the top side of the L-shaped hole 7. Rod 8, and the bottom end of the L-shaped rod 8 extends into the arc-shaped groove 5, the L-shaped rod 8 is compatible with the arc-shaped groove 5, and two L-shaped holes 7 are provided with long grooves on the inner wall of the side away from each other 9, and a movable block 32 is slidably installed in the long groove 9, and a rack 10 is fixedly installed on the side where the two movable blocks 32 are close to each other, and a movable ...

Embodiment 3

[0039] refer to Figure 1-5 , a harmonic drive reduction mechanism, including a rigid gear 1, a flexible gear 2 and an anti-displacement cover 3, two grooves 4 are respectively opened on the rigid gear 1, and the inner walls of the two grooves 4 are close to each other. An arc-shaped groove 5 is provided, and a cavity 6 is provided inside the anti-displacement cover 3, and an L-shaped hole 7 is provided on the inner wall of both sides of the cavity 6, and an L-shaped hole 7 is rotated on the inner wall of the top side of the L-shaped hole 7. Rod 8, and the bottom end of the L-shaped rod 8 extends into the arc-shaped groove 5, the L-shaped rod 8 is compatible with the arc-shaped groove 5, and two L-shaped holes 7 are provided with long grooves on the inner wall of the side away from each other 9, and a movable block 32 is slidably installed in the long groove 9, and a rack 10 is fixedly installed on the side where the two movable blocks 32 are close to each other, and a movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com