Automobile generator rotor size measuring device

A technology of automobile generator and measuring device, applied in the field of machinery, can solve problems such as affecting efficiency, complicated operation, etc., and achieve the effects of improving measurement accuracy, avoiding interference, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

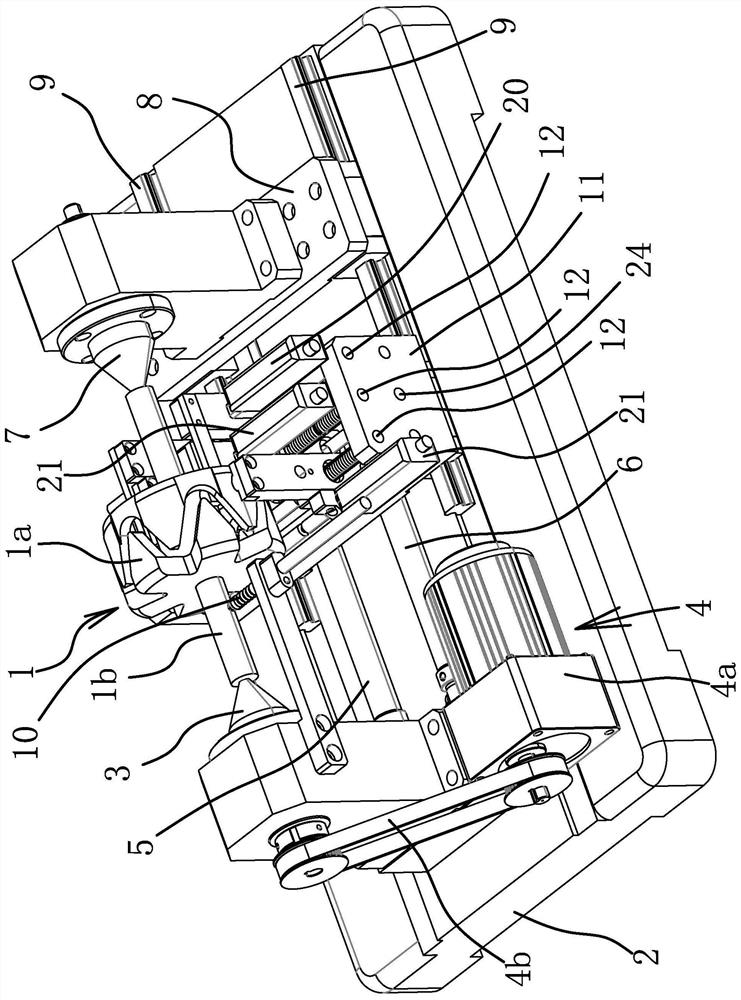

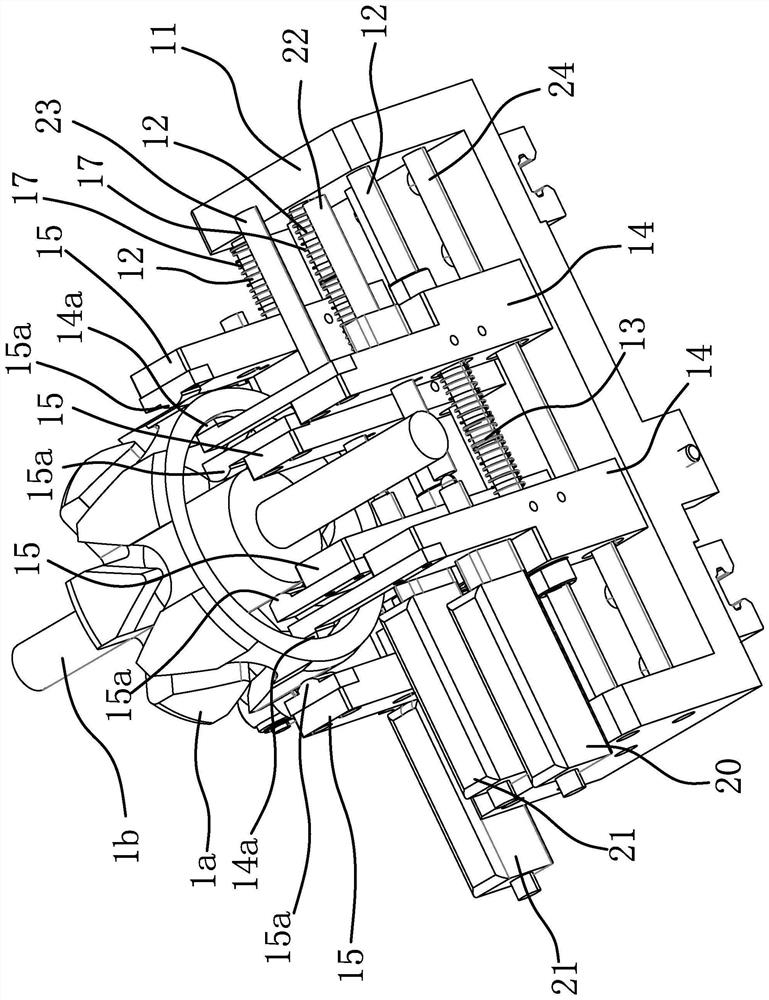

[0034] Such as figure 1 As shown, the automobile generator rotor includes an annular claw pole 1a and a shaft body 1b penetrating the claw pole 1a. The device for measuring the rotor size of an automobile generator includes a base 2, a top 3 arranged on the base 2, and a driving source 4 for driving the top 3 to rotate.

[0035] Wherein, the top 3 is rotatably connected with the base 2, and in this embodiment, the rod of the top 3 is rotatably connected with the base 2 through multiple sets of bearings. The driving source 4 includes a motor 4a fixed on the base 2 and a driving mechanism for connecting the motor 4a and the center 3. In this embodiment, the motor 4a is arranged on one side of the center-1, and the driving mechanism includes a driving wheel fixed on the main shaft of the motor 4a and a driven wheel fixed on the end of the center-1, and the driving wheel and the driven wheel are synchronized With 4b connection. Naturally, the driving source 4 can also be a motor 4a...

Embodiment 2

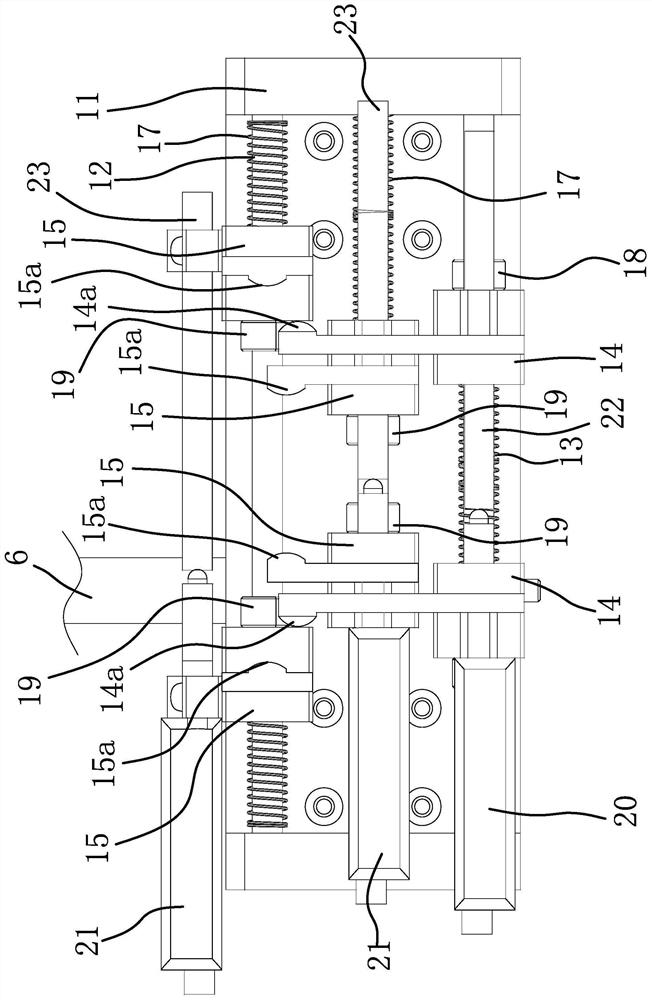

[0052] The structure and principle of the second embodiment are basically the same as those of the first embodiment. The difference lies in: the limiting structure one includes the ring body one fixed on the corresponding guide rod 12 and the convex ring one and two formed on the guide rod 12 The base block 14 is located between the convex ring one and the ring body one, and under the action of the spring 13, the two base blocks 14 press against the ring body one and the convex ring one respectively.

Embodiment 3

[0054] The structure and principle of the third embodiment are basically the same as those of the first embodiment. The difference lies in: the limiting structure one includes two convex rings two formed on the corresponding guide rod 12, and the two convex rings two are located in a pair of base blocks 15 Under the action of the spring assembly, the two base blocks 15 respectively press against the two convex rings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com