Coupling lens capable of realizing incident light and return light detection

A coupling lens and lens technology, applied in the field of coupling lenses, can solve problems such as easy assembly tolerance, and achieve the effect of simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

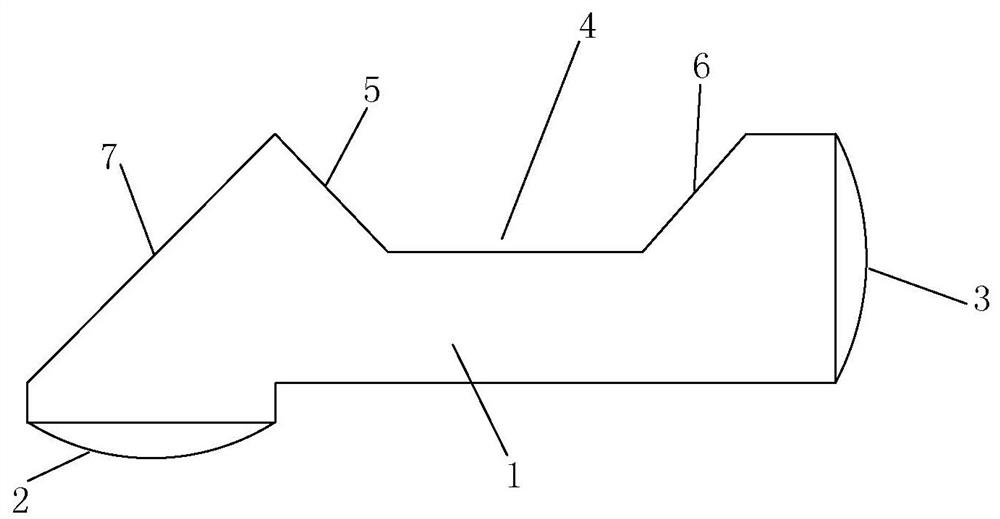

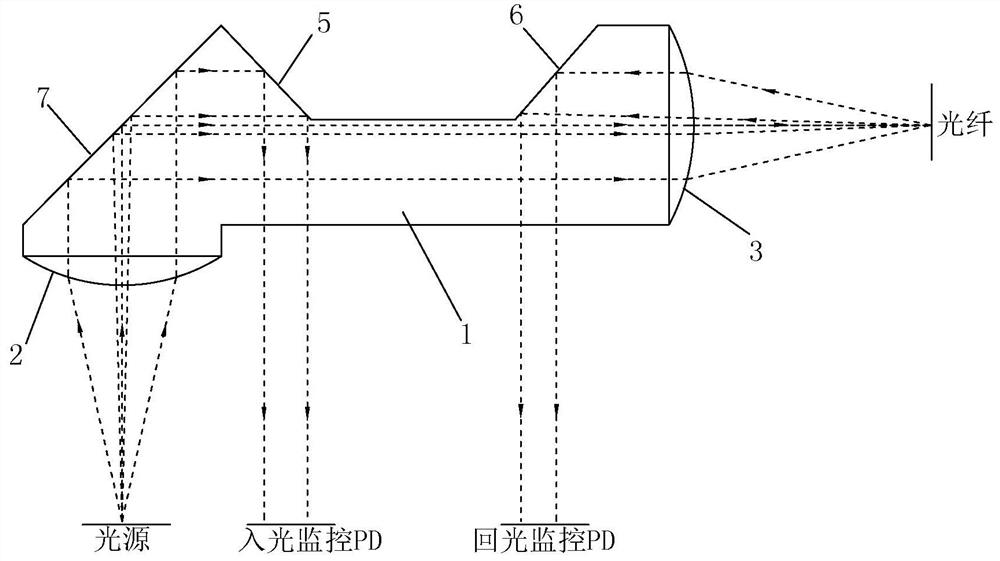

[0018] refer to figure 1 and figure 2 As shown in , the present invention discloses a coupling lens capable of detecting incident light and returning light, including a lens body 1, on which is provided a light incident collimator lens 2 corresponding to light incident from a light source, and used for The light-emitting focusing lens 3 that focuses the incoming light of the incoming light-collimating lens 2 and emits light; the lens body 1 is provided with a trapezoidal groove structure 4 that is recessed into the optical path; the trapezoidal groove structure 4 includes a The part of the incident light entered by the lens 2 is totally reflected and emitted to the second total reflection surface 5 on the incident light monitoring PD, and the part of the returned light returned by the outgoing light focusing lens 3 is totally reflected and emitted to the third total reflection surface 5 on the returned light monitoring PD. The reflection surface 6; the second total reflectio...

Embodiment 2

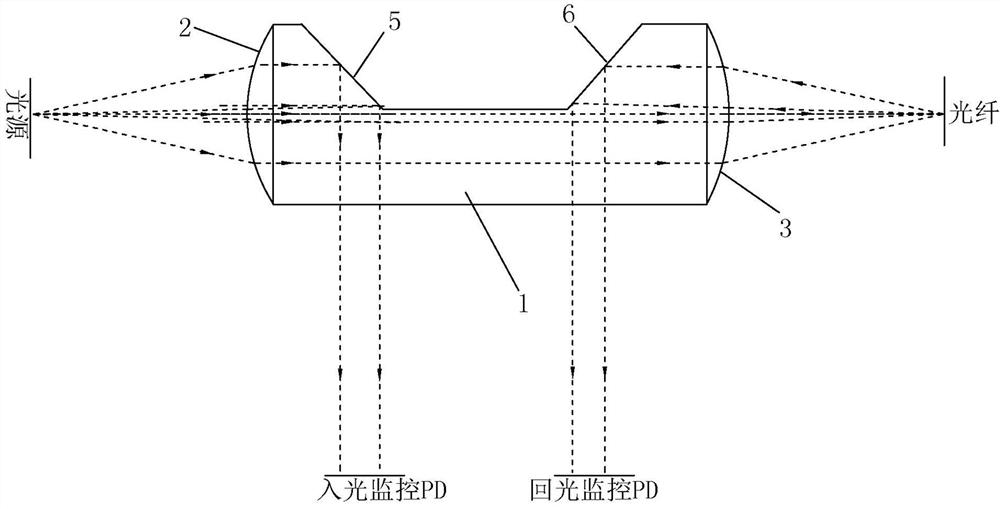

[0026] refer to image 3 As shown in , the difference between this embodiment and embodiment 1 is that the first total reflection surface 7 is cancelled, and other structural principles are the same as embodiment 1, that is, specifically the incident light collimating lens 2 and the light exit focusing lens 3 Located on opposite sides of the lens body 1, the axis of the incident light collimating lens 2 and the axis of the outgoing light focusing lens 3 are on the same straight line; part of the incident light of the incident light collimating lens 2 is directed to the second total reflection surface 5, The rest of the light exits directly onto the focusing lens 3 ; part of the returned light from the exiting focusing lens 3 directly strikes the third total reflection surface 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com