Device of preventing screw from inclining

A screw and bushing technology, used in screwdrivers, manufacturing tools, wrenches, etc., can solve the problems of screw tilt, low efficiency, unqualified batches, etc., and achieve the effect of ensuring the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

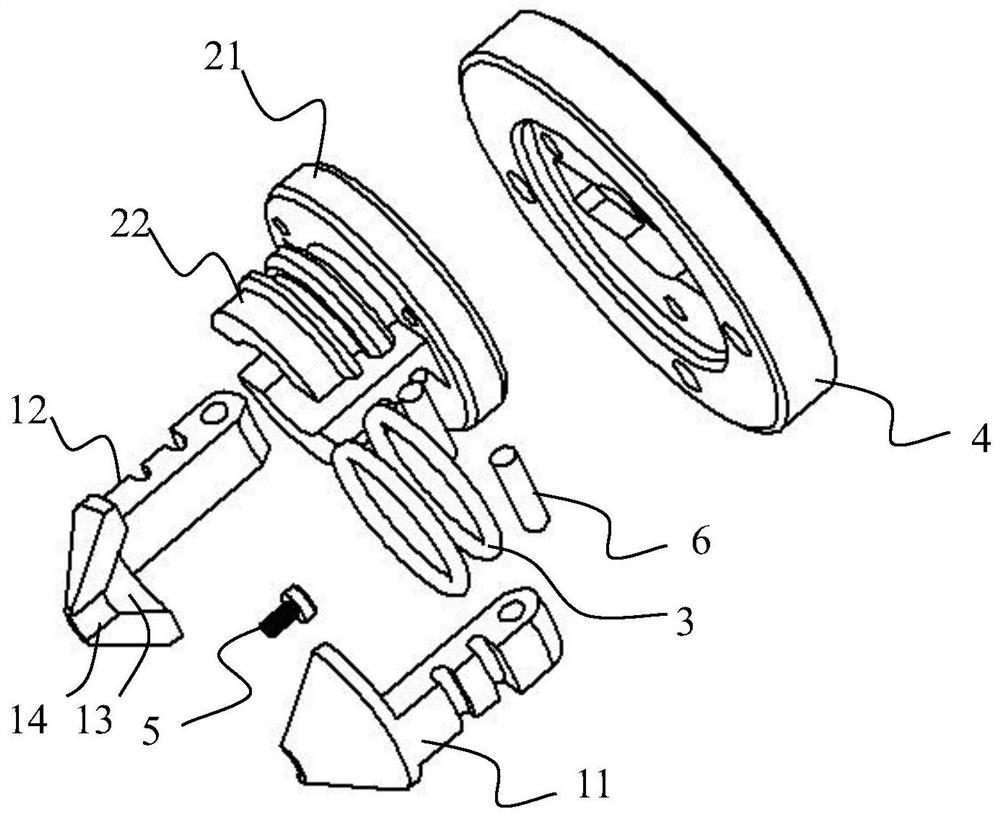

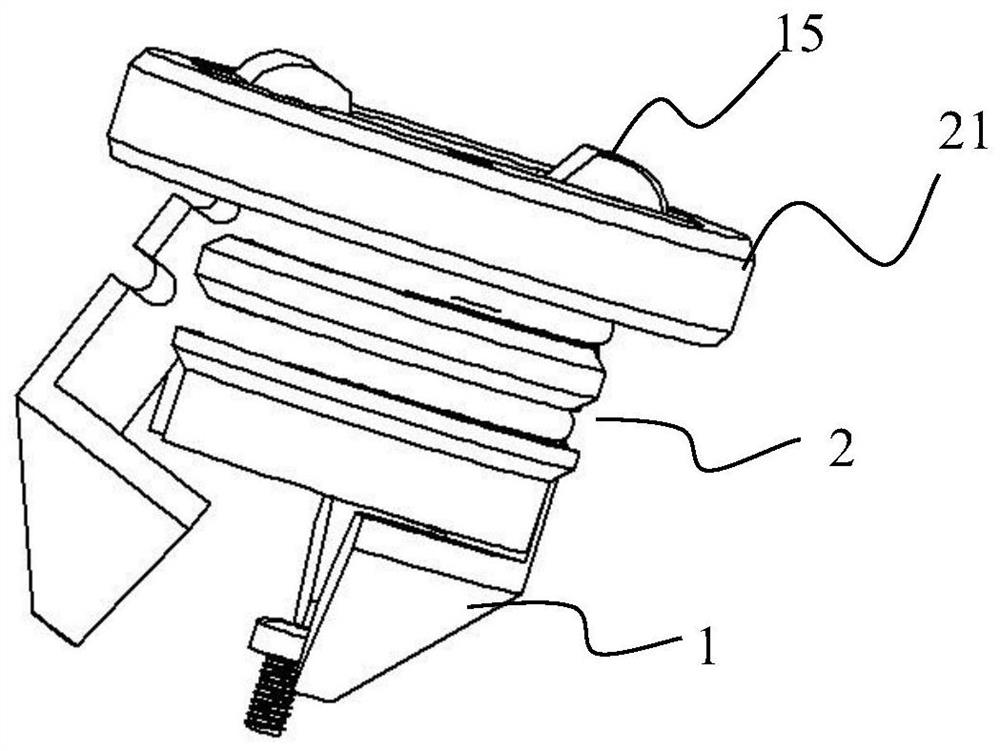

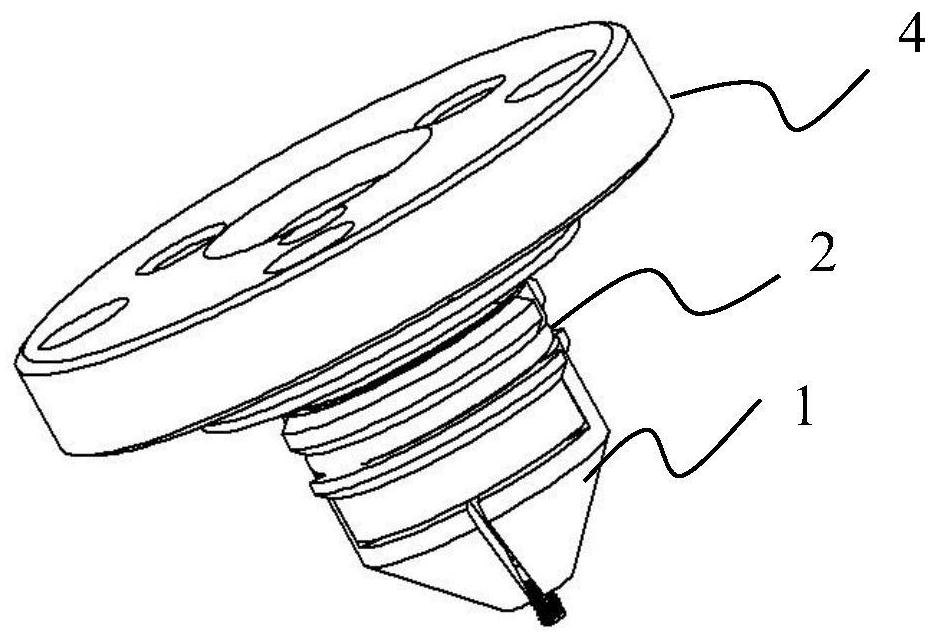

[0027] refer to Figure 1 to Figure 6 , which includes a bushing wall 1, a bushing body 2, an elastic clamping member, and a fixing ring 4, wherein the bushing wall 1 is oppositely arranged for clamping a screw 5, and the bushing body 2 and the The elastic clamping part is used to control the bushing wall to provide a certain pressure when changing its position relative to the bushing body 2 .

[0028] Specifically, the bushing wall 1 has two, respectively a first bushing wall 11 and a second bushing wall 12, the first bushing wall 11 and the second bushing wall 12 are arranged oppositely, and The screw part of the screw 5 is clamped from the opposite side of the screw 5.

[0029] The inner middle part of the lower half of the bushing wall has a first groove 13, and the first groove 13 is adapted to the outer diameter of the screw rod of the screw 5, and the first bushing wall 11 and the The second bushing wall 12 clamps the screw from different parts of the outer diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com