Sweepback wing type propelling efficiency improving device

A technology of propulsion efficiency and swept wings, applied in the direction of rotary propeller, rotary propeller, etc., can solve the problem of weakening energy saving effect, and achieve the effect of good energy saving effect, overcoming drag reduction, and short design cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

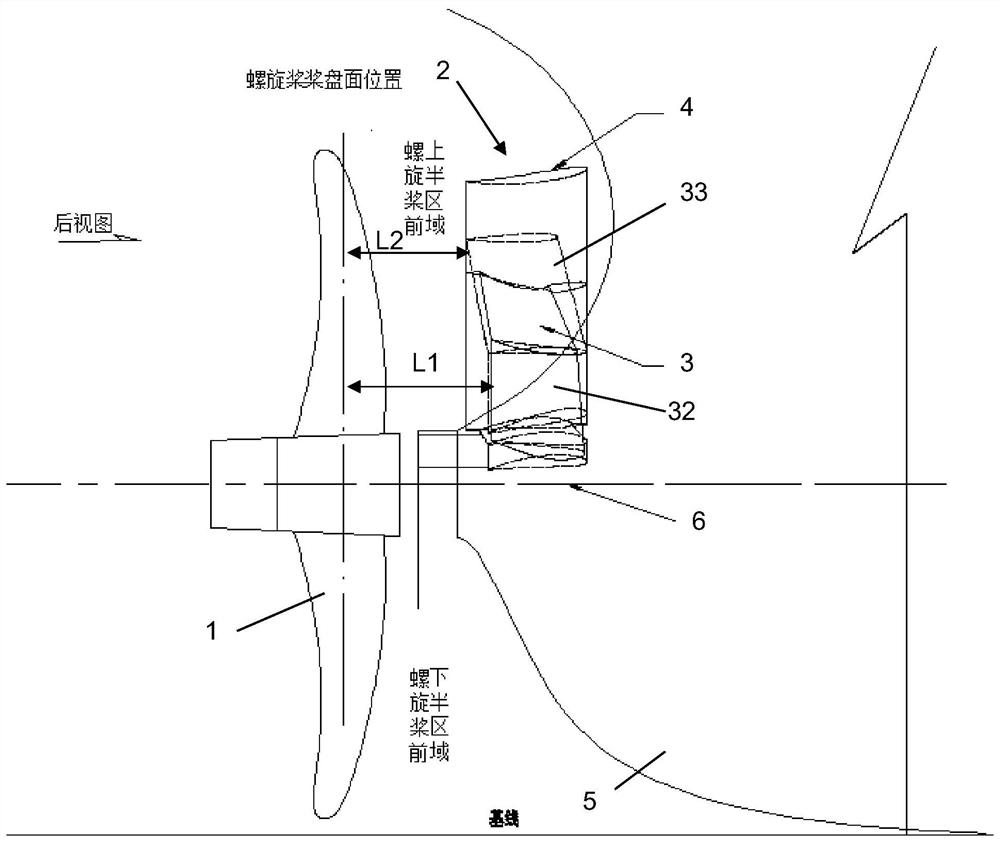

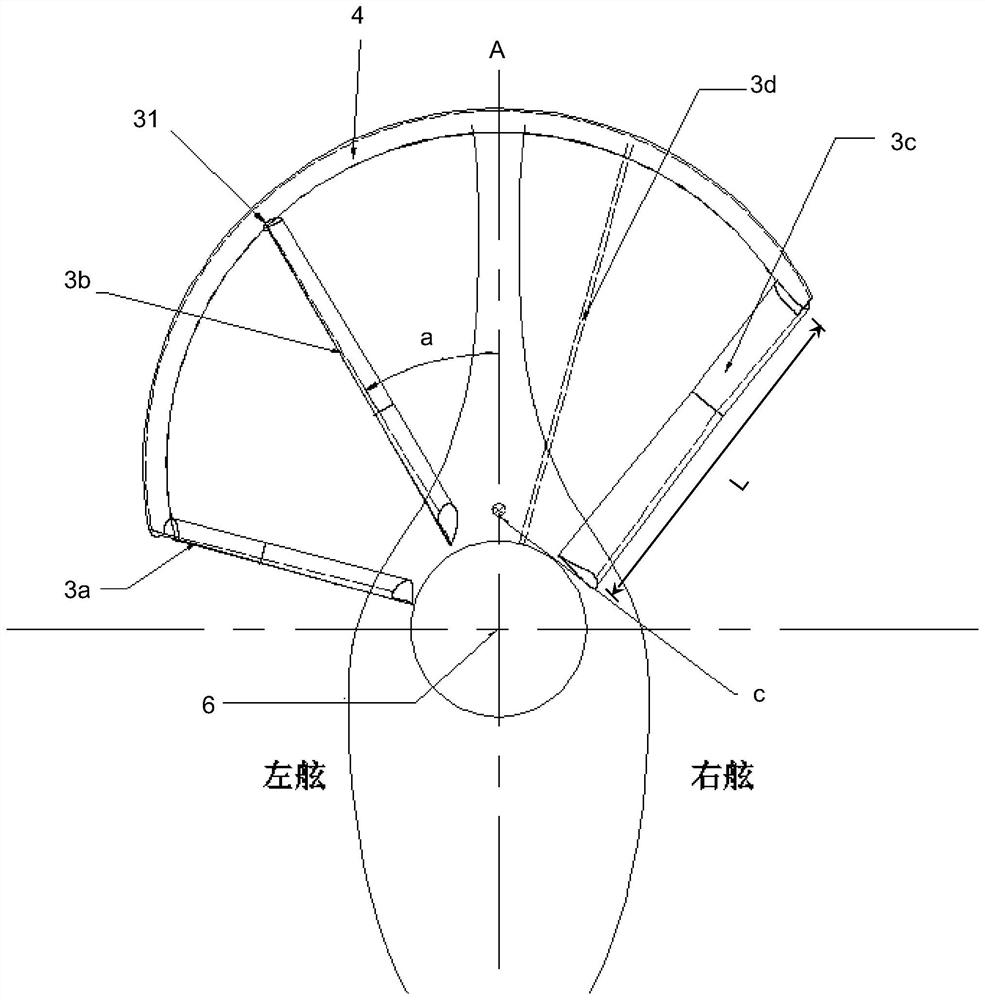

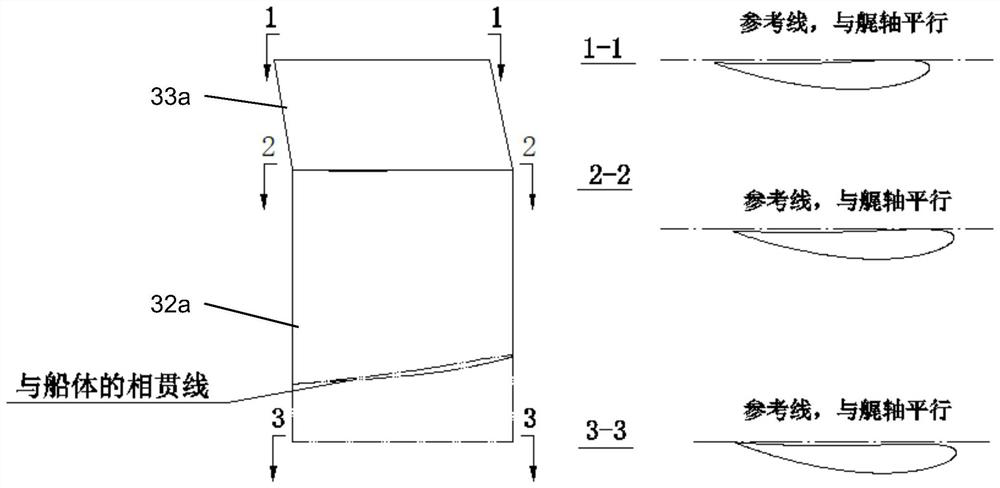

[0022] The swept wing propulsion efficiency improvement device of the present invention is as Figure 1-Figure 2 As shown, the same as the prior art, it also includes the propeller 1 located at the stern and the front guide wheel 2 located in the front area of the propeller 1. The difference is that the front guide wheel 2 includes several pieces of swept back Wing guide vanes 3 and arc ducts 4 installed on the tips 31 of the guide vanes 3, each swept wing guide vane 3 includes front wings 32 arranged radially along the stern axis 6 of the hull 5 and connected to the hull 5, The rear wing 33 is connected to the upper end of the front wing 32 and is inclined backward (that is, toward the propeller 1 located behind). The front wing 32 is connected to the hull 5 by welding, and the connection position is near the stern shaft 6 of the hull 5. The front wing 32 is relatively far away from the propeller 1, and the distance between it and the surface of the propeller 1 is 15%-25% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com