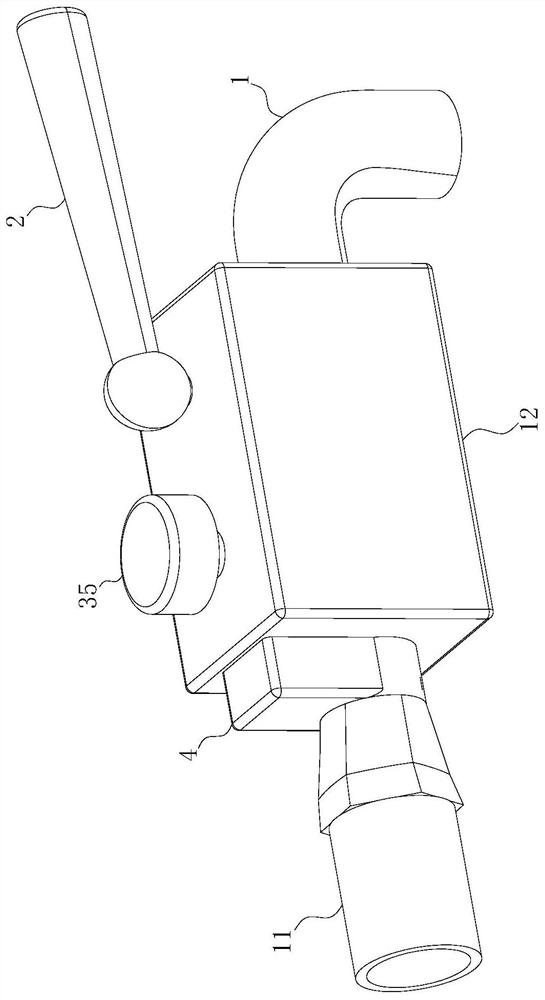

A plastic pipe fitting valve

A technology of plastic pipe fittings and valves, which is applied in the field of pipe fittings and valves for packaging products, can solve the problems of poor valve control effect, weak water pressure and flow rate effect, lightly turning the switch, etc., to avoid water leakage, avoid excessive water pressure, and reduce opening The effect of closing times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

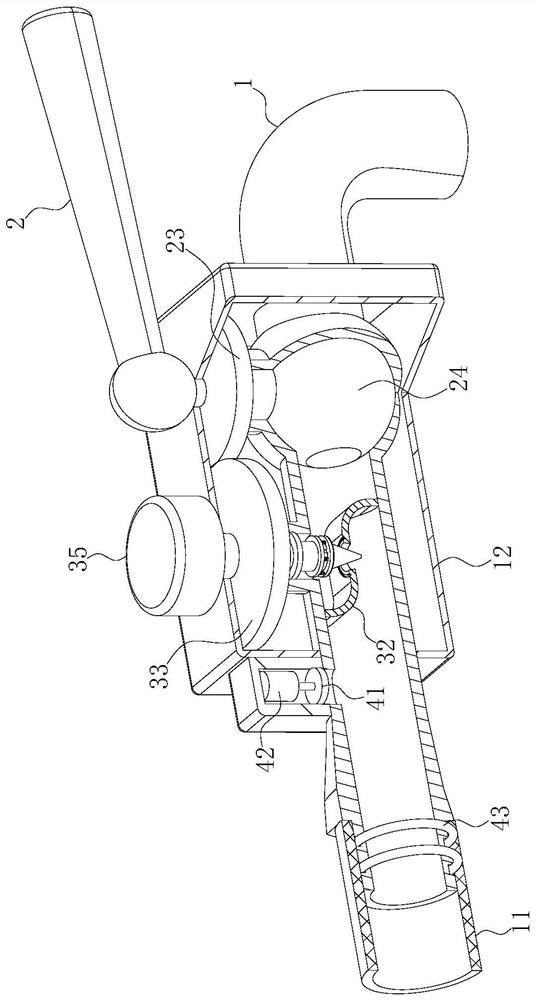

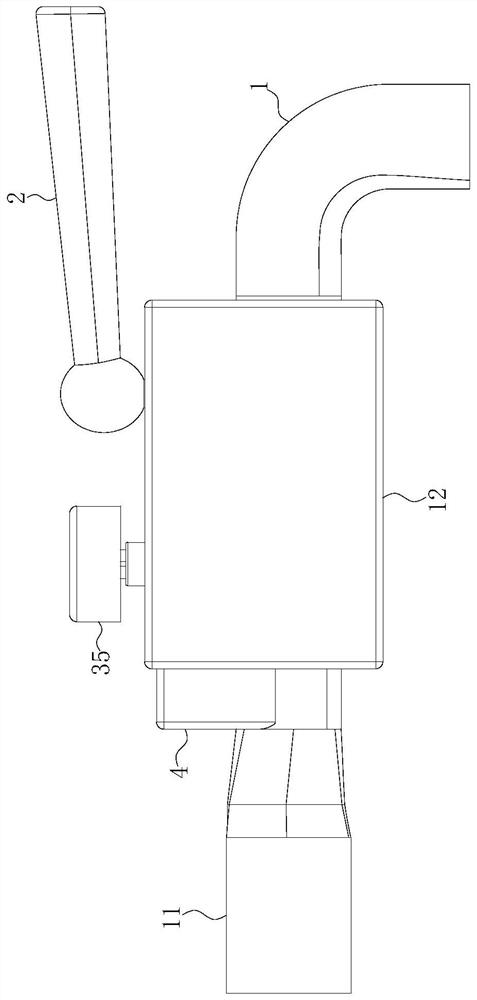

[0027] As an embodiment of the present invention, the inner arc surface of the second regulating pipe 31 is tapped with a second threaded hole below the first regulating pipe 21; the internal thread of the second threaded hole is connected with a spool 34 The axial position of the spool 3 is provided with a perforation that penetrates up and down, and the upper end surface of the valve core 34 passes through the perforation and extends to the outside of the installation box 12; Cap 35; when working, because the linkage between the spool 3 and the rotating handle 2 is realized through the meshing connection between the first gear 23 and the second gear 33, the spool 3 cannot be adjusted independently. , the flow resistance cannot be further reduced, and when the linkage mechanism is not installed in place, the problem that the two control valves cannot be closed synchronously will easily occur. Therefore, by setting the spool 34 and connecting the spool 34 with the internal thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com