Leveling instrument capable of intelligently marking and positioning

A technology of level and marking, applied in the field of level, can solve the problem of not being able to clamp synchronously, and achieve the effect of facilitating horizontal installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

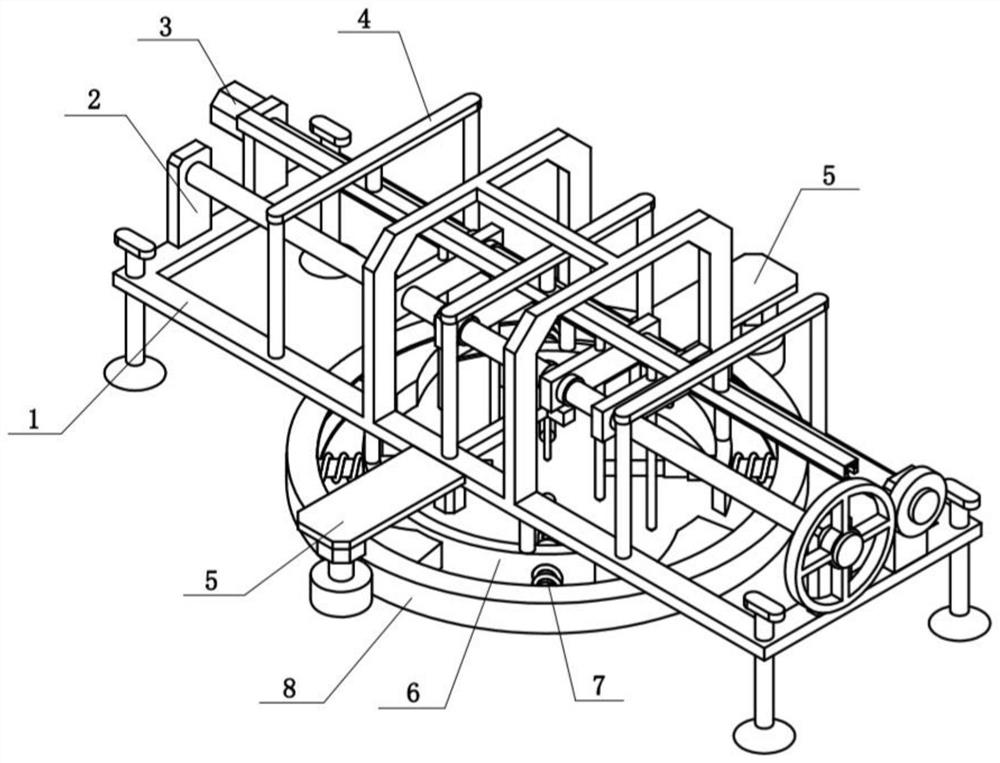

[0029] Combine below Figure 1-8 Describe this embodiment, the spirit level that can be intelligently marked and positioned includes a horizontal adjustment assembly 1, a synchronous adjustment assembly 2, a driving motor 3, a marking positioning assembly 4, a driving assembly 5, a guiding assembly 6, a fixing assembly 7 and a synchronous clamping assembly 8. The synchronous adjustment assembly 2 is fixedly connected to the horizontal adjustment assembly 1, the drive motor 3 is fixedly connected to the left side of the synchronous adjustment assembly 2, the mark positioning assembly 4 is fixedly connected to the horizontal adjustment assembly 1, and the drive assembly 5 has two , two driving assemblies 5 are respectively fixedly connected to the front and rear sides of the level adjustment assembly 1, there are two guide assemblies 6, the two guide assemblies 6 are respectively fixedly connected to the front and rear sides of the level adjustment assembly 1, and there are four ...

specific Embodiment approach 2

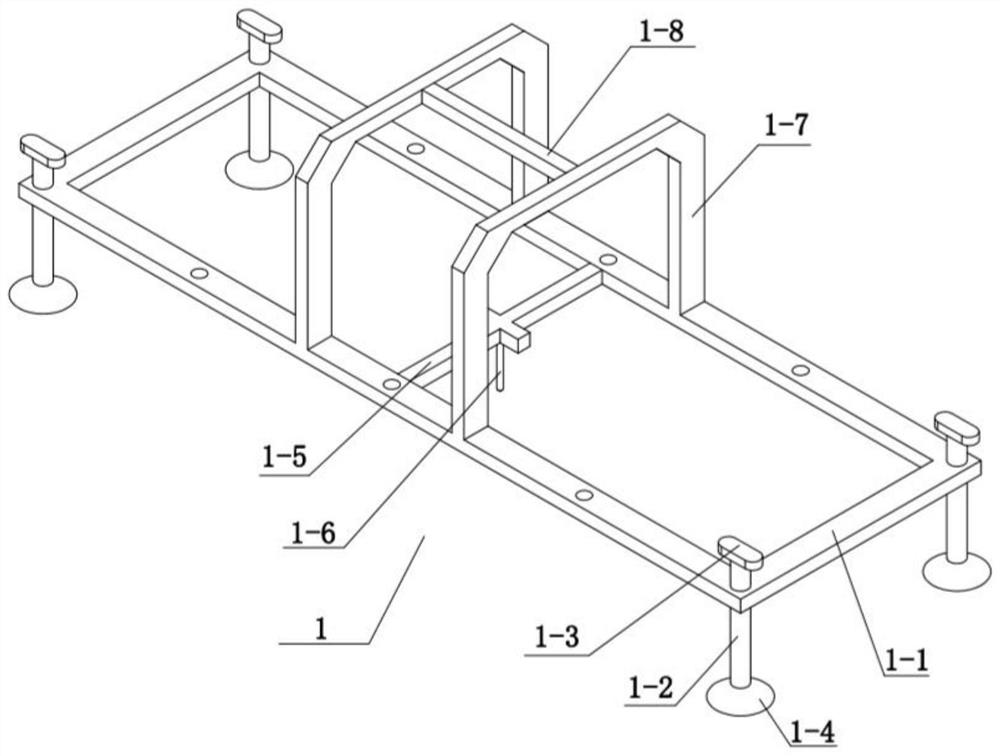

[0032] Combine below Figure 1-8To illustrate this embodiment, the level adjustment assembly 1 includes a back frame 1-1, a lifting screw 1-2, an adjustment handle 1-3, a suction cup 1-4, a cross level 1-5, and a midpoint marker 1-6 , double fixed frame 1-7 and beam 1-8, the four corners of back frame 1-1 are all threaded with lifting screw rod 1-2, and the upper ends of four lifting screw rods 1-2 are all fixedly connected with adjusting handle 1-3, the lower ends of the four lifting screws 1-2 are rotatably connected with a suction cup 1-4, the cross level 1-5 is fixedly connected to the middle of the back frame 1-1, and the midpoint marking pen 1-6 is threadedly connected to the cross The lower end of the spirit level 1-5, two double fixed mounts 1-7 are respectively fixedly connected to the left and right sides of the middle part of the word frame 1-1, and the crossbeam 1-8 is fixedly connected to the two double fixed mounts 1-7.

[0033] The four suction cups 1-4 are ads...

specific Embodiment approach 3

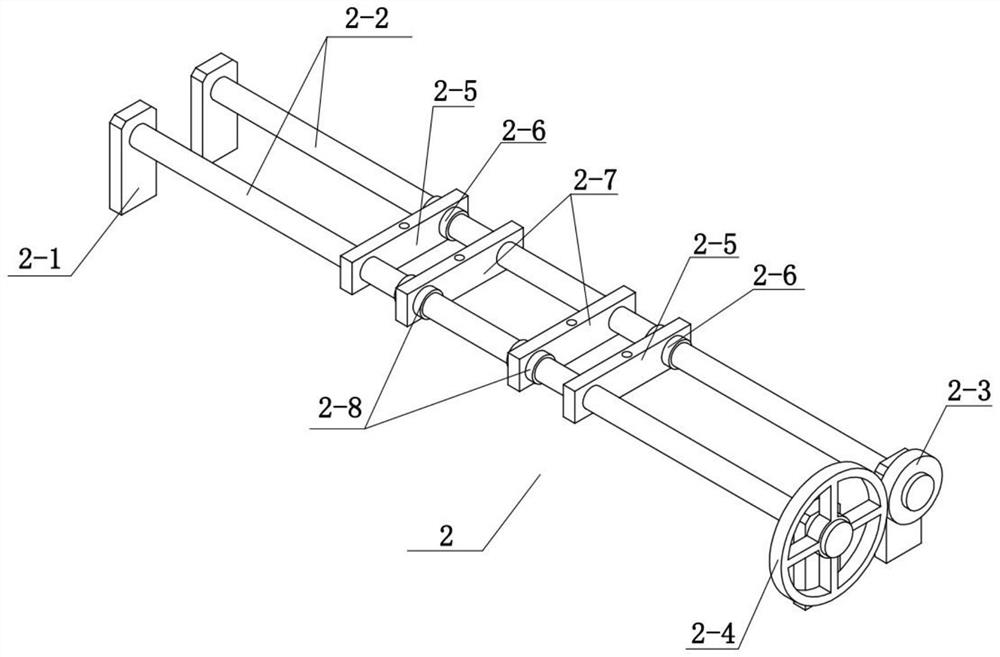

[0035] Combine below Figure 1-8 To illustrate this embodiment, the synchronous adjustment assembly 2 includes a screw fixing plate 2-1, a screw 2-2, a high-speed gear 2-3, a low-speed gear 2-4, a double transmission plate 2-5, and a high-speed threaded sleeve 2 -6, the low-speed drive plate 2-7 and the low-speed threaded sleeve 2-8, the left and right ends of the word frame 1-1 are fixedly connected with two screw fixing plates 2-1, and the two screw mandrels 2-2 rotate respectively Connected to the two pairs of screw fixing plates 2-1 corresponding to the left and right, the driving motor 3 is fixedly connected to the screw fixing plate 2-1 on the rear side of the left end, and the high-speed gear 2-3 is fixedly connected to the screw rod 2-2 at the rear end The screw rod 2-2 at the rear end is fixedly connected to the output shaft of the drive motor 3, the low-speed gear 2-4 is fixedly connected to the screw rod 2-2 at the front end, and the high-speed gear 2-3 and the low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com