A kind of installation method of apron base and apron motor

A skirt board and trigger technology, which is applied in the installation field of skirt board bases and skirt board motors, can solve the problems of easy damage of skirt board bases, reduce time cost and replacement cost, not easy to swing, and simple maintenance methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

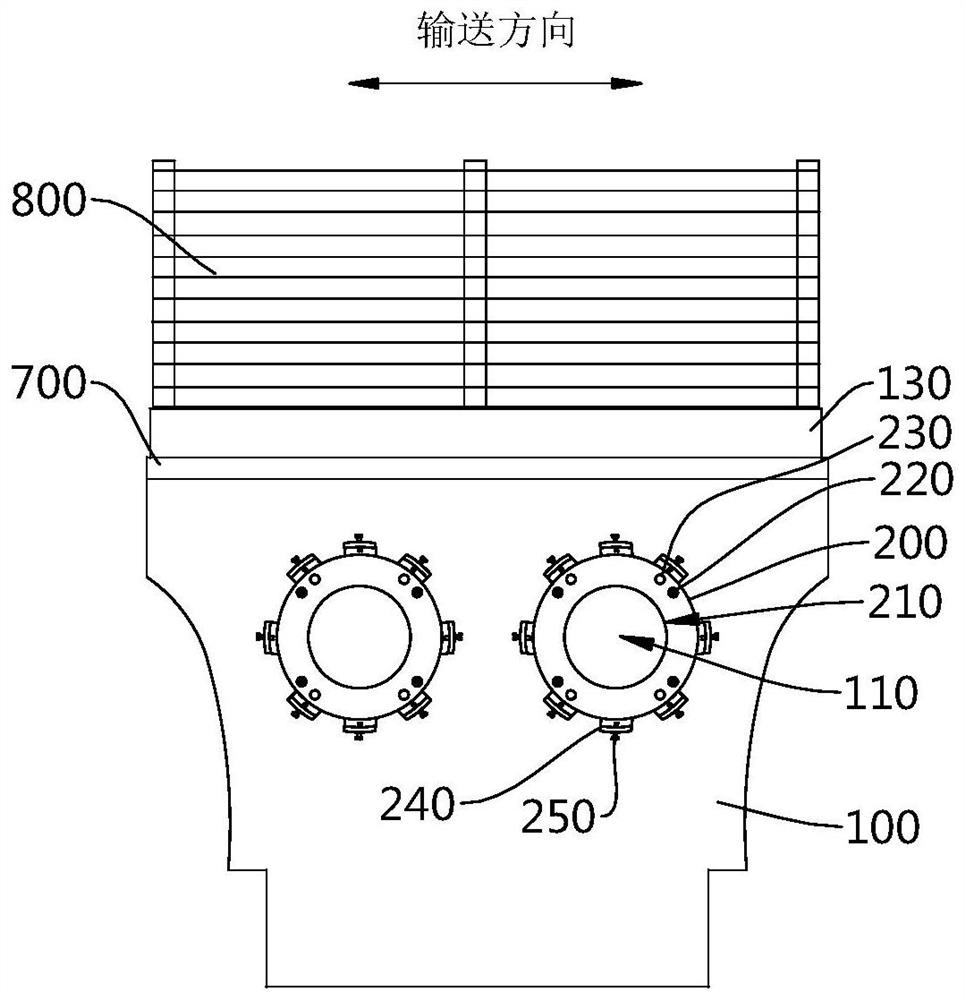

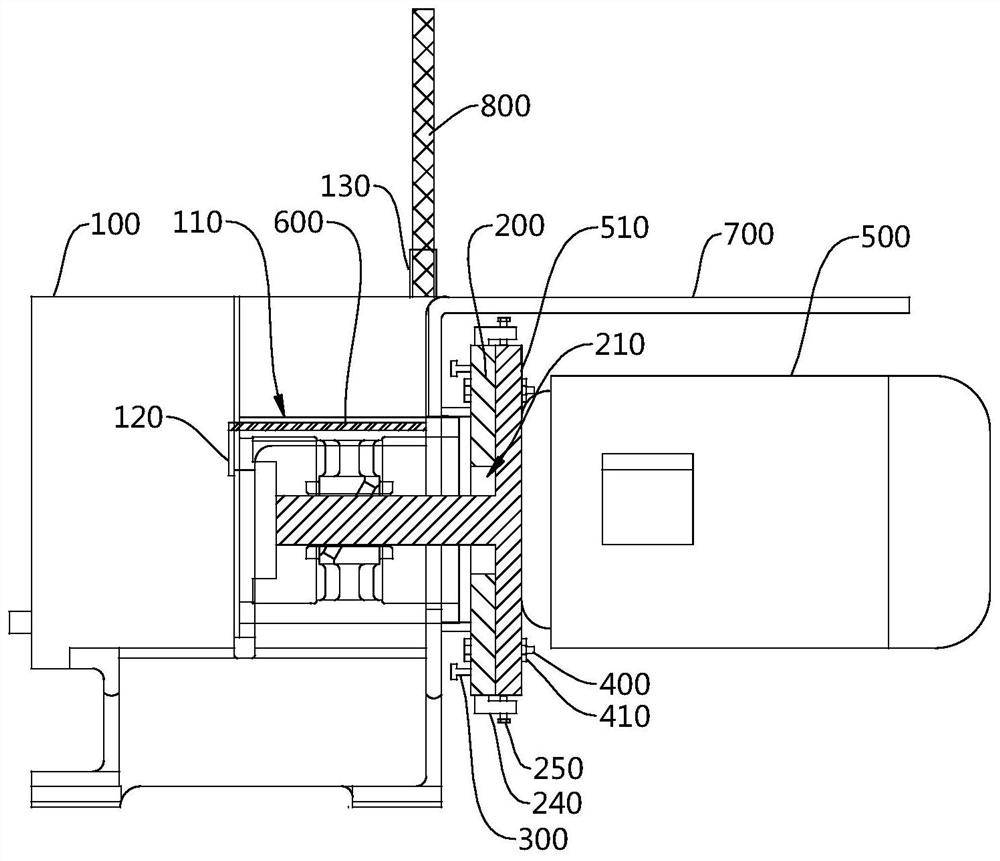

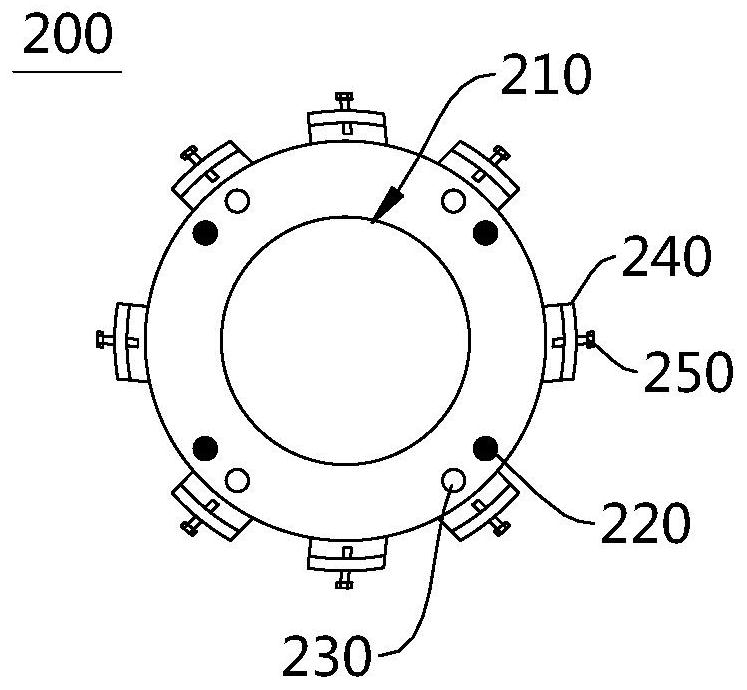

[0043] In the prior art, four bumps are formed on the skirt board base as mounting positions for the skirt board motor, screw holes are formed on the bumps, and screws are used to pass through the motor base of the skirt board motor to connect to the screw holes of the bumps. After working for a long time, the skirt board base is under tension for a long time, and the screw holes of the protrusions are subjected to torque for a long time, which is easy to be damaged, which will cause the motor seat to loosen, and when the skirt board motor vibrates, its overall swing relative to the skirt board base increase, which is more likely to cause damage to the apron machine seat, and the apron roller is also easy to swing or interfere with the inner wall of the apron channel, resulting in the unstable steel rod being transported on the apron roller, and the steel rod is easy to fly out of the apron machine seat, there is a greater security risk. Therefore, once the motor base is loose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com