Cutting treatment device for building-used bars and pipes

A processing device and cutting device technology, applied in sawing machine devices, metal sawing equipment, metal processing equipment, etc., can solve the problems of bar or pipe pinching, different lengths, and poor adjustment of the inclination angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

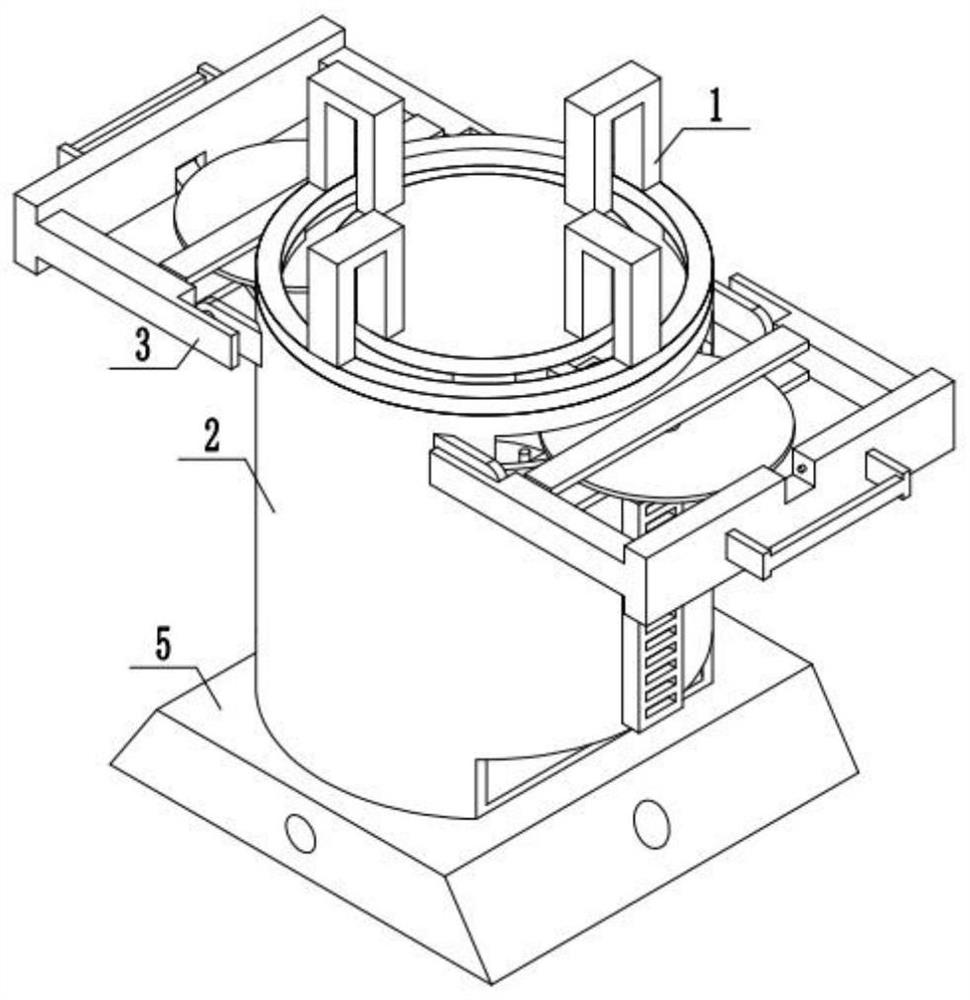

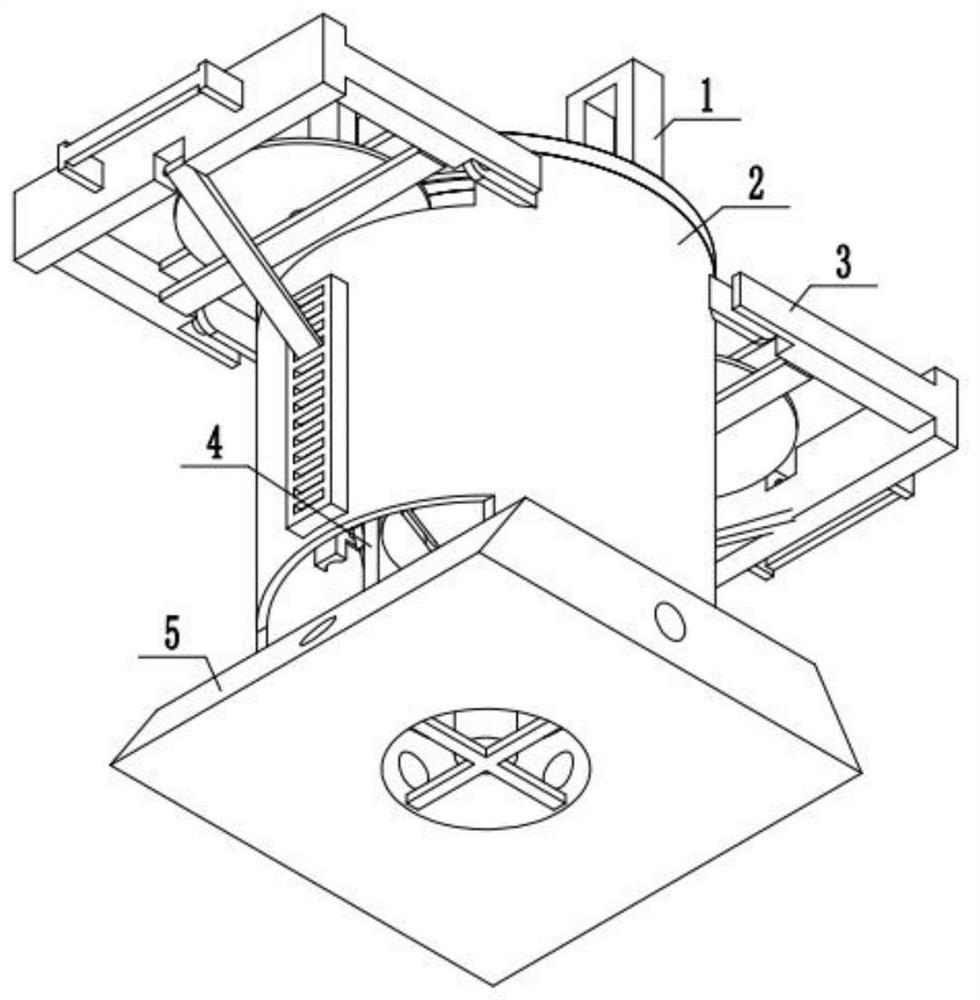

[0038] Combine below figure 1 , 2Description of this embodiment, a device for cutting and processing rods and pipes for construction, including a device upper cover body 1, a cutting outer shell 2, a cutting device 3, a rod and pipe driving device 4 and a device fixing base 5, and the device is installed on the fixing base 1 There is a protective outer shell 2, the device upper cover 1 is located above the cutting outer shell 2, the cutting device 3 is fixedly installed on the protective outer shell 2, the rod and pipe driving device 4 is fixedly installed above the device fixing base 5, and the cutting device 3 On the device fixed base 5.

specific Embodiment approach 2

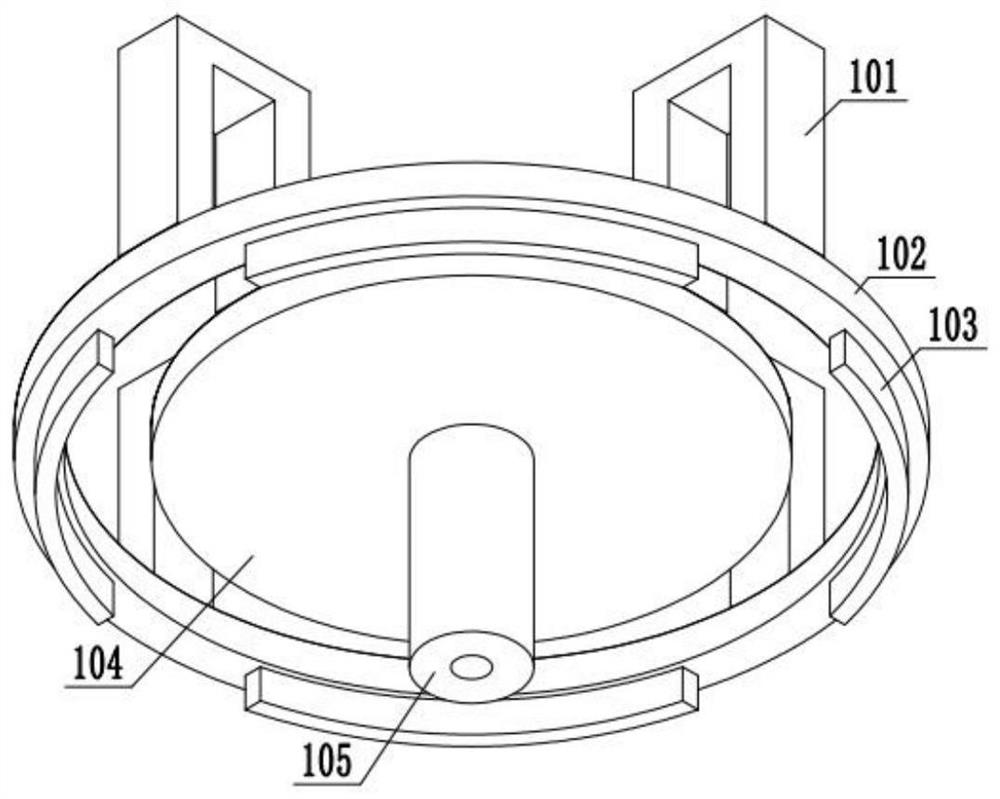

[0040] Combine below image 3 , 4 Describe this embodiment, this embodiment will further explain Embodiment 1, the upper cover body 1 of the device includes an avoidance connecting frame 101, an outer cover body 102, an arc-shaped block 103, an inner cover body 104, and a connecting shaft sleeve 105, The avoidance connecting frame 101 is fixedly installed on the outer cover body 102, and the below of the outer cover body 102 is fixedly equipped with an arc-shaped block 103, and the inner cover body 104 is fixedly installed on the avoiding connecting frame 101, and the avoiding connecting frame 101 is provided with four, each The cloth is installed on the inner cover body 104, and the connecting shaft sleeve 105 is fixedly installed under the connecting shaft sleeve 105. The connecting shaft sleeve 105 is set on the rod and pipe driving device 4, which can prevent the vibration of the rod and pipe driving device 4 and avoid the connection. The frame 101 is set in an arched sha...

specific Embodiment approach 3

[0042] Combine below Figure 5 , 6 Describe this embodiment, this embodiment will further explain Embodiment 1. The cutting device 3 includes a connecting block 301, a driving frame 302, a driving handle 303, a fixed connecting frame 304, a power motor A305, a cutting saw blade 306, and an adjusting rod 307, fixed clamping plate 308, connecting block 301 is fixedly installed on the protective shell body 2, two connecting blocks 301 are provided, the driving frame 302 is installed on the connecting block 301 through the movement of the shaft, and the driving frame 302 is fixedly installed with a driving handle 303 , the fixed connecting frame 304 is fixedly installed on the driving frame 302, the power motor A305 is fixedly installed on the driving frame 302, the output end of the power motor A305 is equipped with a cutting saw blade 306, and the cutting saw blade 306 is installed on the fixed connecting frame 304 through the shaft. On the top, the adjusting rod 307 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com