A material feeding structure for an extruder used in the production of plastic steel profiles

A technology of extruder and profile, which is applied in the field of new feeding structure of extruder for plastic steel profile production, can solve the problems of reducing labor force, difficult maintenance, low mixing uniformity of raw and auxiliary materials, etc., to achieve uniform mixing and reduce labor force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

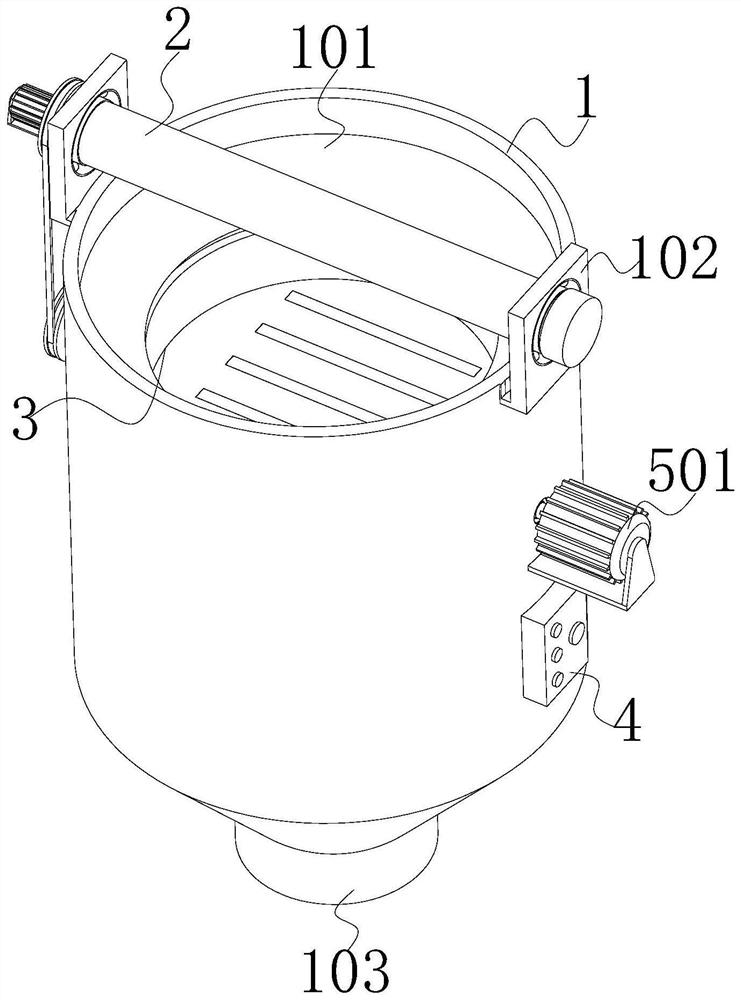

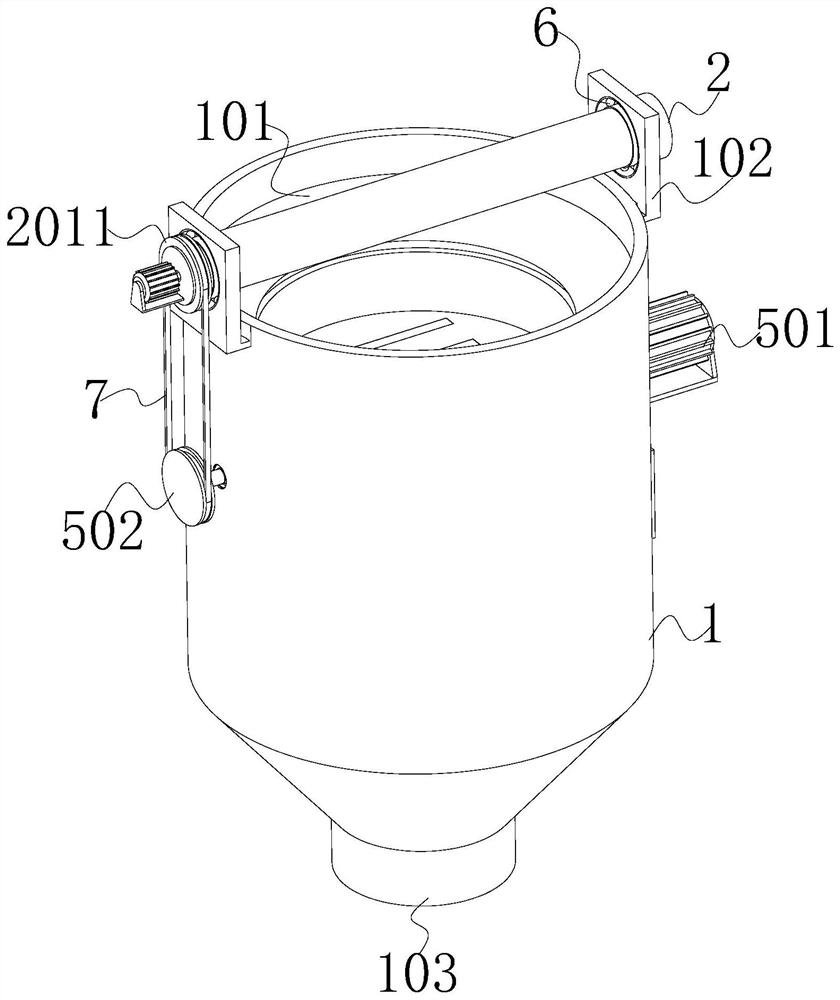

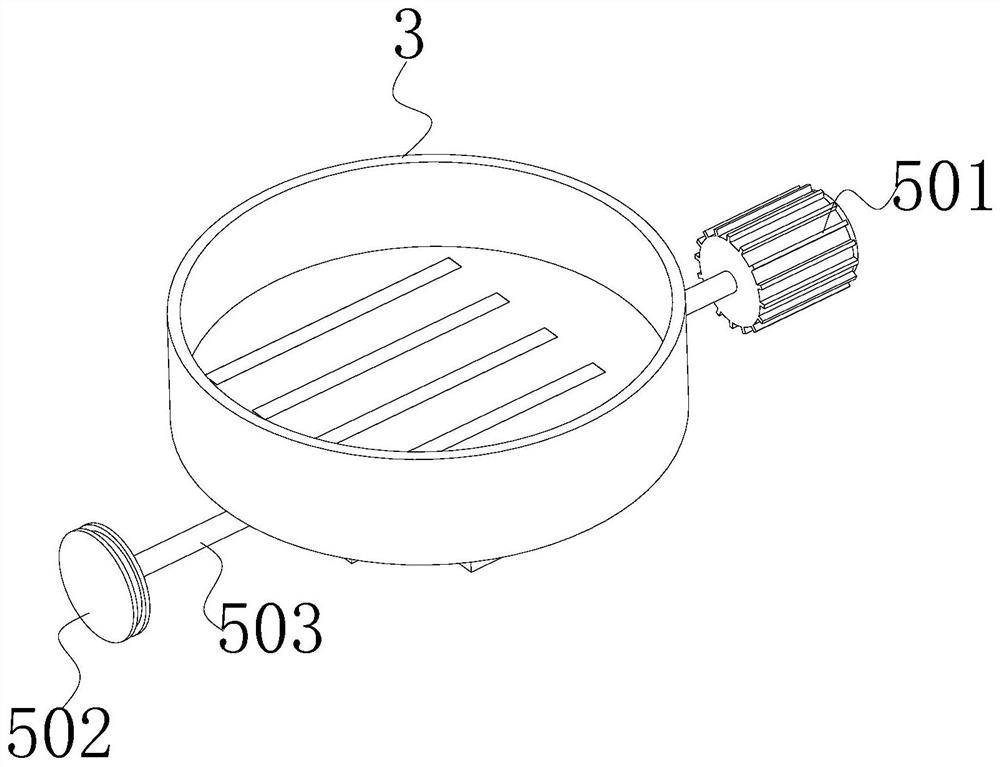

[0053] see Figure 1-2 As shown in and 7, the present invention is a new type of feeding structure for an extruder used in the production of plastic steel profiles, including a feeding hopper 1, an auxiliary material adding mechanism 2 and a mixing barrel 3, and the upper part of the feeding hopper 1 is fitted with a mixing barrel 3 , the setting of the mixing cylinder 3 is used for the mixing of raw and auxiliary materials. An auxiliary material adding mechanism 2 is arranged directly above the center line of the hopper 1, and a plurality of discharge grooves 301 are arranged side by side on the bottom surface of the mixing cylinder 3, and the discharge grooves 301 and The auxiliary material adding mechanism 2 is arranged in parallel, which can realize that the swing direction of the mixing cylinder 3 is parallel to the direction of the auxiliary material adding mechanism 2, so that the raw and auxiliary materials can be mixed more evenly;

[0054] The bottom surface of the f...

Embodiment 2

[0076] Based on the new material feeding structure of the extruder used for the production of plastic-steel profiles described in Example 1, a feeding mechanism is provided on the upper side of the feeding hopper 1 to facilitate the addition of raw materials into the mixing cylinder 3 .

[0077] In addition, in order to reduce the frequency of fillers in the auxiliary material adding mechanism 2, the staff can increase the number of partition plates 2031 according to needs, thereby increasing the number of placement slots, realizing the number of times of automatic addition of auxiliary materials, while the corresponding number of placement slots increases, The discharge holes 2032 and the second discharge grooves 2041 increase in the same number.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com