Keyless lock cylinder

A keyless lock, lock cylinder technology, applied in the direction of turning key locks, combination locks, building locks, etc., can solve the problems of easy to be unlocked by tools, lost, easy to damage keys, etc., to achieve good anti-theft effect, solve easy damage and easily lost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

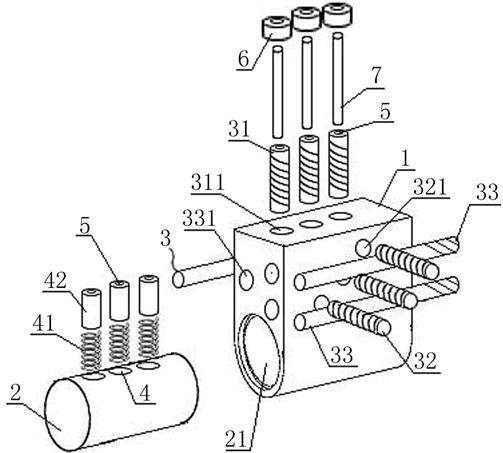

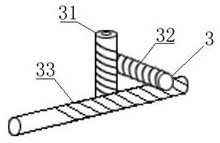

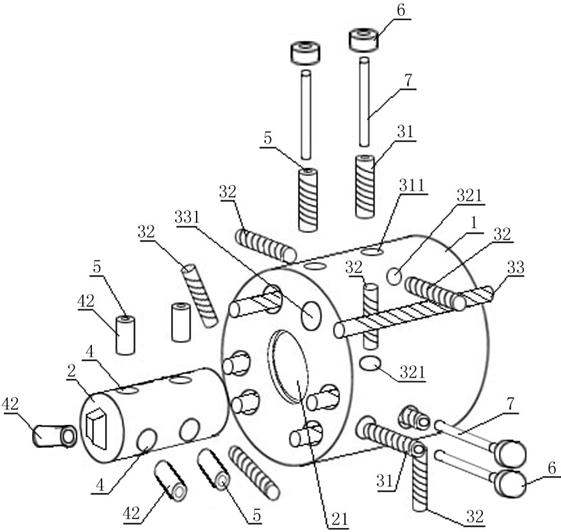

[0021] A keyless lock cylinder such as figure 1 , 2 , 3, including a lock case 1, a lock cylinder 2, and an unlocking assembly 3; the lock case 1 is provided with a cylinder hole 21, and the lock cylinder 2 is rotatably arranged in the cylinder hole 21; the lock case 1 is provided with a round hole 311 , the transmission hole 321, the unlocking hole 331, one end of the round hole 311 is connected with the lock cylinder hole 21, the other end runs through the lock housing 1, the transmission hole 321 is connected with the round hole 311, the unlocking hole 331 runs through the lock body and connects with the transmission hole 321 The unlocking assembly 3 includes a lock case pin 31, a transmission rod 32, and an unlocking rod 33, the lock case pin 31 is arranged in the circular hole 311, the transmission rod 32 is arranged in the transmission hole 321, and the unlocking rod 33 is arranged in the unlocking hole 331; The shell pin 31, the transmission rod 32, and the unlocking r...

Embodiment 2

[0028] As the preferred scheme of embodiment 1, such as figure 1 , 2 , 3, the transmission hole 321 is vertically connected to the circular hole 311; the unlocking hole 331 runs through the lock housing 1 and is vertically connected to the transmission hole 321.

[0029] The transmission hole 321 and the lock hole 21 are straight lines in different planes, and the angle between the transmission hole 321 and the lock hole 21 is 0-180 degrees, preferably 90 degrees, and the transmission hole 321 is connected with the round hole 311, and The included angle is from 0° to 180°, preferably 90° and vertically connected. The transmission hole 321 can also pass through the lock housing 1 and connect with the round hole 311 .

[0030] The unlocking hole 331 and the lock hole 21 are straight lines on different planes, and the angle between the unlocking hole 331 and the lock hole 21 is 0° to 90°, preferably 0°, parallel to each other, and the unlocking hole 331 and the transmission hole...

Embodiment 3

[0033] As the specific scheme of embodiment 1, such as figure 1 , 3 As shown, the number of the unlocking components 3 is at least one group, and the positions of the round hole 311, the transmission hole 321, and the unlocking hole 331 are set in one-to-one correspondence with the lock shell pin 31, the transmission rod 32, and the unlocking rod 33.

[0034] When there are multiple groups of unlocking components 3, each group of unlocking components 3 is arranged staggeredly, and the lock shell pins 31 in different unlocking components 3 adopt different lengths respectively. By setting the lock shell pins 31 of different lengths, different lock shell pins 31 The travel distances in the circular holes 311 are different, and then relative to the corresponding inner pin hole 4, the unlocking lever 33 needs to be rotated by different angles to control the stroke of each individual lock shell pin 31, thereby realizing a single lock. When the shell pin 31 is inserted into the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com