Converter valve trigger architecture for realizing live-line fault processing

A live treatment and converter valve technology, applied in the direction of power transmission AC network, output power conversion device, electrical components, etc., can solve the problems of inaccessibility, trigger pulse interruption, etc., to improve reliability, improve safety, reduce The effect of the risk of forced outage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

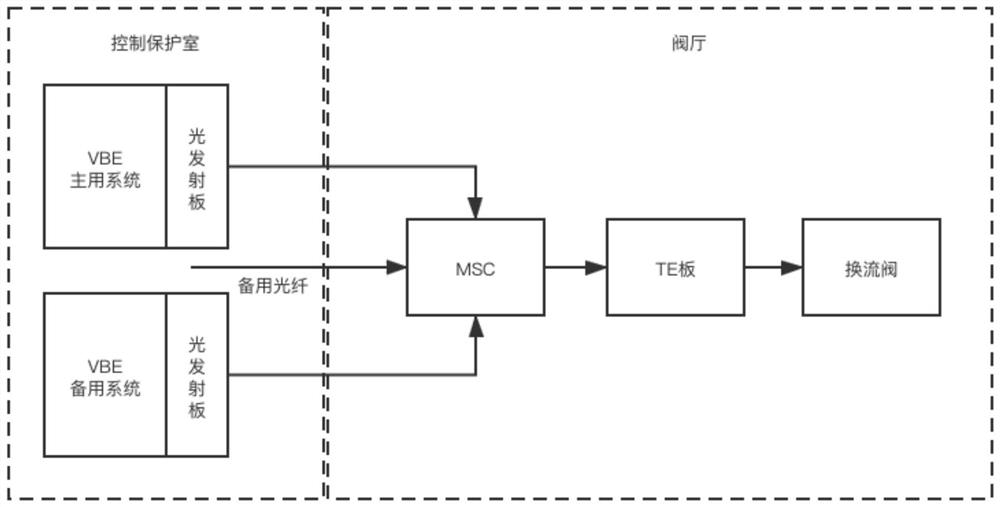

[0017] like figure 1 As shown in the figure, the present invention is a converter valve triggering structure for realizing live processing of faults, including a thyristor electronic board connected to the converter valve signal, and the thyristor electronic board is located in the valve hall; it also includes a VBE main system and a VBE backup system, the VBE The main system and the VBE backup system are located in the control protection room, and the VBE main system and the VBE backup system are respectively installed with a first light emitting board and a second light emitting board.

[0018] The thyristor electronic board is connected with the MSC module of the optical fiber coupler through the optical fiber signal, the entrance of the MSC module is respectively preset with the main optical fiber, the standby optical fiber and the preset op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com